When graphite anodes approach their theoretical capacity limit, who will become the “energy engine” of next-generation lithium batteries? With an ultra-high specific capacity of 1800 mAh/g, silicon-carbon anode is accelerating from laboratory research to large-scale industrialization—this is not just a material upgrade, but a revolution in energy density.

Core Types of Anode Materials and Technical Features

Graphite-Based Anodes

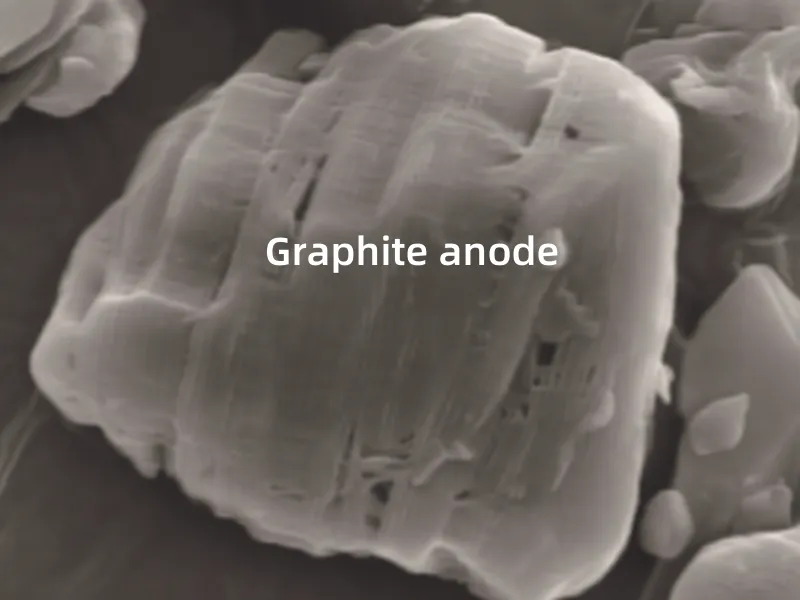

Natural Graphite

- Features: Theoretical capacity of 340–370 mAh/g, low cost, but low initial Coulombic efficiency (~80%) and solvent co-intercalation risks leading to structural peeling.

- Application: Mainly in consumer electronics (3C).

Artificial Graphite

- Features: Produced by graphitizing petroleum coke/needle coke at high temperatures (2800°C). Uniform structure, cycle life >2000 cycles, initial efficiency >90%.

- Application: Power batteries (over 70% of the anode market).

Silicon-Based Anodes

Technical Routes:

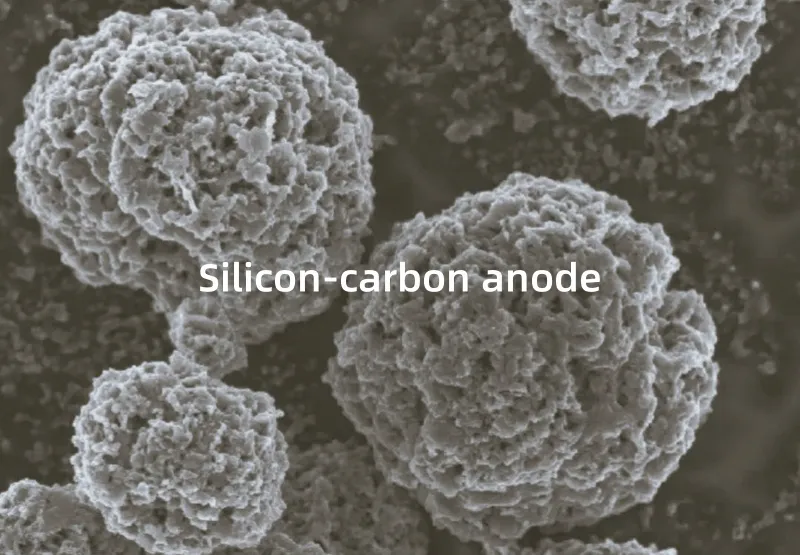

- Silicon-Carbon Anode: Nano-silicon particles embedded in a carbon matrix, capacity 400–600 mAh/g, volume expansion reduced to 30% (vs. 300% for pure silicon).

- Silicon-Oxide Anode (SiOx): Silicon suboxide composite with graphite, capacity 450–500 mAh/g, volume expansion <50%, better cycling performance.

Advantages: Theoretical specific capacity of 4200 mAh/g (10× graphite), excellent fast-charging performance, abundant resources.

Production Processes and Core Technologies

Artificial Graphite Production

Process: Raw material crushing → mechanical milling → granulation/coating → high-temperature graphitization → sieving & shaping

Core Steps:

- Crushing: Break petroleum coke into suitable particle size.

- Granulation: Refine into secondary particles, uniform powder (6–10 μm).

- Graphitization: Transform carbon atoms into ordered graphite crystalline structures.

Silicon-Based Anode Production

Process: Silicon source → thermal decomposition → amorphous nano-silicon + porous carbon skeleton → vapor deposition silicon-carbon → CVD carbon coating

Core Steps:

- Silicon Nano-sizing: Ball mill/ultrasonic dispersion to <100 nm.

- Composite Coating: CVD carbon coating, graphene doping to suppress volume expansion.

- Structural Design: Porous silicon, core–shell architectures to enhance conductivity.

Technical Challenges and Breakthrough Directions

High Volume Expansion

- Silicon expands by >300% during cycling, causing particle pulverization and electrode failure.

- High-silicon content (>15%) exacerbates the issue, limiting practical applications. Current content is usually kept below 10%.

Low Initial Coulombic Efficiency (ICE)

- Repeated SEI film formation on silicon consumes lithium ions. ICE only 70%–85% (vs. >95% for graphite).

High Costs

- CVD silicon-carbon costs ~¥500,000/ton (vs. ¥20,000/ton for artificial graphite).

- Main reasons: high cost of porous carbon (resin-based up to ¥500,000/ton) and silane (~¥100,000/ton), plus complex and hazardous processes.

Immature Supporting Materials

- Current binders and electrolytes are not well-suited for silicon-carbon’s high expansion, requiring customized solutions.

Innovation Directions for Silicon-Carbon Anodes

1. Structural Design Innovations

- Porous carbon skeleton + CVD deposition: Nano-silicon (5–10 nm) is deposited inside pores, mitigating expansion.

- Case: Spherical silicon-carbon with improved compressive strength (3–5× higher), wrinkled surface for better electrolyte wetting; 6th-gen products achieved <20% expansion, >1000 cycle life, ICE >90%.

2. Process Optimization

- CVD Upgrades: Scaling from 20 kg to 100 kg per furnace, localization of equipment, and mass-production lines (5000-ton plants stable, new lines exceeding 10,000 tons/year). Industry average cost reduced to ~¥220,000/ton.

- Pre-lithiation Breakthroughs: Using LiF–Li₂C₂O₄ composite SEI films, ICE improved from 75% to 88% (close to graphite’s 95%), with 50% lower interfacial resistance.

3. Performance Benchmarking

- Optimized CVD silicon-carbon: Specific capacity 1800–2000 mAh/g, cycle life >1000 cycles, electrode expansion controlled at 25%–27%.

- Performance significantly outperforms conventional SiOx anodes (capacity ~1500 mAh/g, ICE 75%–80%).

Epic Powder

With silicon-carbon anodes driving the next leap in lithium battery energy density, advanced material processing has become the key to industrialization. Epic Powder, with its expertise in ultra-fine grinding, ball milling, and powder classification technologies, provides tailored equipment solutions to prepare nano-silicon and high-performance carbon composites—paving the way for scalable, cost-effective, and reliable silicon-carbon anode production.