Lithium batteries mainly consist of the anode, cathode, separator, electrolyte, binder, conductive agent, current collector, and packaging materials. According to material form classification, the anode, cathode, binder, and conductive agent are powder materials in Lithium batteries. Some solid-state electrolytes are powder materials, and some modified separators also contain powder materials.

Positive Electrode

Commercialized positive electrode materials include Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (LiMn2O4), NCM (LiNixMnyCozO2), and Lithium Iron Phosphate (LiFePO4).

- Lithium Cobalt Oxide (LiCoO2): A black solid at room temperature. It is an inorganic compound known for its stability, simple synthesis, high electrochemical performance, and long cycle life. It is the first commercially successful cathode material for lithium-ion batteries and is mainly used in 3C batteries.

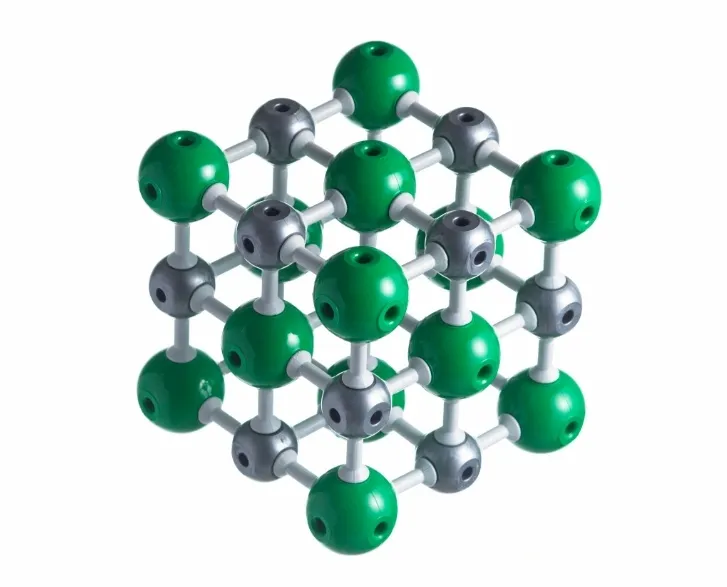

- Lithium Manganese Oxide (LiMn2O4): A black-grey powder with a cubic spinel crystal structure. It contains three lithium ion transport channels, enabling faster ion diffusion. This makes it suitable for high-rate charge lithium-ion batteries.

- Ternary Positive Material (LiNixMnyCozO2): A ternary cathode material where Ni and Mn partially replace Co in LiCoO2. It inherits the stability of LiCoO2, high reversible capacity of LiNiO2, and safety of LiMnO2. The lower Co content reduces costs, making it a promising cathode material.

- Lithium Iron Phosphate (LiFePO4): With an olivine structure, it does not contain expensive elements like Co or Ni. It is cost-effective, with abundant raw materials. It has a moderate working voltage (3.2V), high specific capacity (170 mAh/g), large discharge power, fast charging capability, and long cycle life.

Negative Electrode

Common negative electrode materials include graphite, hard carbon, soft carbon, lithium titanate, and silicon-based materials. Graphite is the most widely used, and silicon-based materials have the most potential.

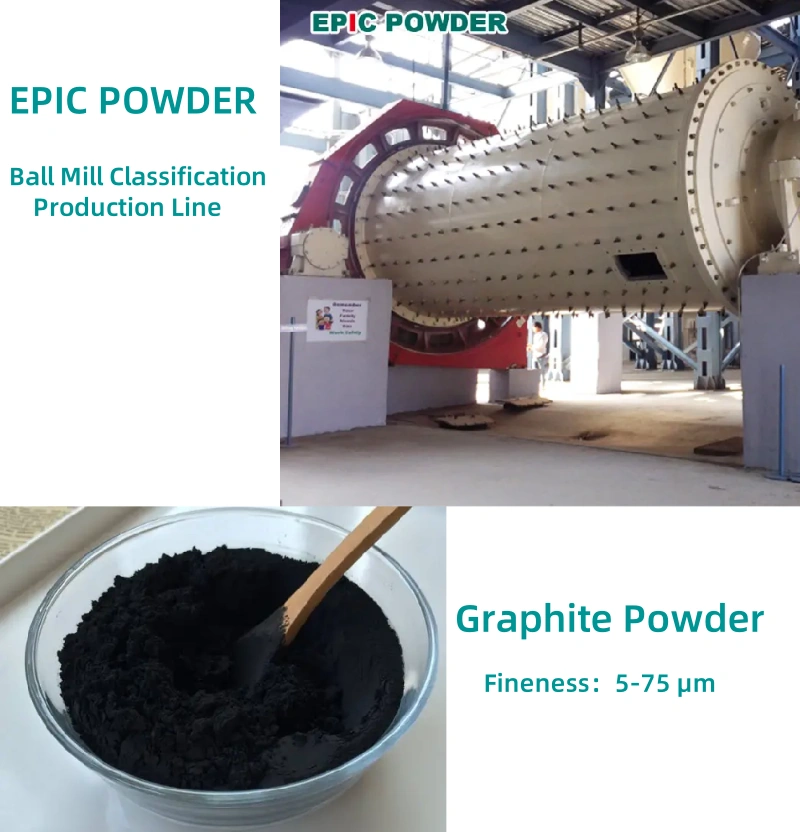

- Graphite: Mainly composed of graphite, it has high conductivity, energy density, chemical stability, and low manufacturing costs. It is available in natural and artificial forms.

- Hard Carbon: It is carbon that does not graphite at high temperatures. It has disordered internal crystal arrangements and a large interlayer spacing, allowing more charge storage, which enhances energy density and battery life.

- Soft Carbon: This material is easily graphitized above 2500°C. It has a high degree of order and provides a low, stable charging/discharging voltage. It offers large capacity, high efficiency, and good cycling performance. Its structure depends on sintering temperature. Soft carbon materials prepared at temperatures below 1000°C have a large number of defects, providing a large number of active sites for lithium storage, which is conducive to the smooth insertion and extraction of lithium ions.

- Lithium Titanate: A white powder with a high lithium ion extraction voltage (1.55V vs Li/Li+). It has high safety and “zero-strain” properties, ensuring minimal structural change during lithium ion insertion and extraction. This offers an unlimited theoretical cycle life. Therefore, it has great research value and commercial application prospects as a negative electrode material for energy storage and power lithium batteries.

- Silicon-Based Materials: Includes nano-silicon and silicon suboxide. These materials are used for silicon-carbon or silicon-oxide anodes. Silicon-based anodes offer much higher specific capacity and energy density than carbon-based materials, making them the most promising next-generation anode materials.

Binders

Binders like Polyvinylidene Fluoride (PVDF) and Styrene-Butadiene Rubber (SBR) are used. PVDF can be used for both the anode and cathode, while SBR is typically used for the anode.

- Polyvinylidene Fluoride (PVDF): PVDF has excellent chemical stability and corrosion resistance. It effectively resists the corrosive effect of electrolyte solvents. It also offers good bonding properties, mechanical performance, and processability. PVDF’s flexibility ensures that active substances do not detach during expansion and contraction.

- Styrene-Butadiene Rubber (SBR): SBR is widely used as a water-based binder, especially in anode binders, where its application accounts for 98%. It offers strong adhesion, mechanical stability, and operational ease. It helps bind particles together and enhances battery dynamics, reducing impedance and improving cycling stability.

Conductive Agents

- Conductive agents are used to ensure good charge/discharge performance by collecting microcurrents and directing them to the current collector (aluminum or copper foil). Common conductive agents include carbon black, vapor-grown carbon fibers (VGCF), and carbon nanotubes (CNT).

- Carbon Black: An amorphous carbon that is a fine, loose black powder. It is produced by the incomplete combustion of organic substances and high-temperature treatment to improve conductivity and purity. It is the most commonly used conductive agent in lithium batteries, improving contact between particles and forming a conductive network.

- Vapor-Grown Carbon Fibers (VGCF): These fibers have high bending modulus and low thermal expansion. Adding VGCF improves flexibility and mechanical stability, making it suitable for long-life, high-output batteries like those used in electric vehicles.

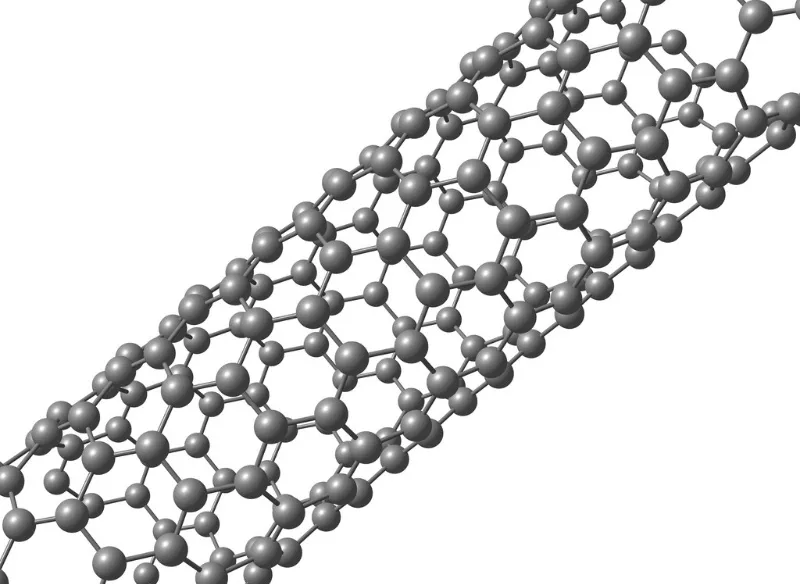

- Carbon Nanotubes (CNT): The impedance of CNT is only half of that of carbon black. Low impedance brings good conductivity, improves polarization, and makes the cycle performance better. The amount of carbon black added is about 3% of the weight of the positive electrode material, while the amount of CNT added is only 0.8%~1.5%. The low addition amount can save space for active materials, thereby increasing energy density. However, CNT is not easy to disperse. At present, the industry generally uses high-speed shearing, adding dispersants, and ultra-fine grinding beads electrostatic dispersion to process it.

Solid-State Electrolytes

Some solid-state electrolytes are also in powder form:

- High Purity Germanium Disulfide (GeS2): A white powder with high ionic conductivity, chemical stability, and long life. It can reach 99.99% purity.

- Lithium Lanthanum Zirconium Oxide (LLZO): This material has excellent ionic conductivity (1.5×10-4S/cm) and is used for solid-state lithium battery preparation. It can be synthesized by sol-gel, low-temperature combustion, microemulsion, and other methods.

- Lithium Lanthanum Zirconium Tantalum Oxide (LLZTO): It offers high ionic conductivity, chemical stability, and thermal stability. By optimizing the preparation process and crystal structure, its electrical properties can be further improved to meet the needs of high-performance solid-state batteries.

Other solid-state electrolyte powders include barium sulfate, lithium phosphorus sulfur chloride (high-stability sulfide), and lithium germanium phosphorous sulfur sulfide.

Battery Separator

Traditional separators have poor stability at high temperatures, impacting safety. To improve safety, separators are modified by adding powder coatings. These modified separators contain powder materials.

- Aluminum Oxide (Al2O3):Aluminum oxide is abundant in nature, with excellent chemical inertness, thermal stability, and mechanical properties. It is commonly used in ceramic separators to improve the overall performance of polyolefin separators. It is also the inorganic powder used in the modification of lithium battery diaphragms in large quantities.

- Boehmite (AlOOH): Boehmite, also known as monohydrated aluminum oxide, is a type of aluminum oxide with crystal water. It is an irreplaceable aluminum oxide precursor. The production of AlOOH is easier than α-Al2O3. In industry, boehmite slurry is obtained by gibbsite hydrothermal method, and then AlOOH ultrafine powder is obtained by filtering, drying and crushing.

- Titanium Dioxide (TiO2): TiO2 is non-toxic, stable, and easy to control in preparation. It enhances separator thermal stability, electrolyte wettability, and reduces interface impedance, thus improving lithium-ion transport. It is a good material for modifying organic polymer separators.

- Silicon Dioxide (SiO2): SiO2 is a common inorganic filler used to modify polymers. Its large surface area and hydroxyl groups (Si-OH) improve separator wettability, enhance lithium-ion transport, and improve electrochemical performance. SiO2 also strengthens the separator’s mechanical strength and prevents dendrite growth, reducing thermal short circuits. Unlike Al2O3, TiO2, and AlOOH, SiO2 is easier to control and modify.

Epic Powder

Epic Powder specializes in providing advanced grinding solutions that are crucial for the production of powder materials in lithium batteries. With our state-of-the-art equipment, such as jet mills, ball mills, and air classifiers, we ensure precise control over particle size and distribution, optimizing the performance of critical battery materials like cathodes, anodes, and conductive agents. Our cutting-edge technologies not only enhance the efficiency of battery manufacturing but also support the development of next-generation solid-state and high-performance batteries. Partnering with Epic Powder means unlocking the potential of your powder materials in lithium batteries for superior energy storage solutions.