In this case study, we will examine how calcium carbonate powder is used. We will also showcase a successful production line that employs an ultrafine pin mill grinding technique. The case study looks at a chemical plant in Taiwan. They’ve used a new process to improve the quality and efficiency of calcium carbonate production.

Application of Calcium Carbonate Powder:

Calcium carbonate powder is widely used in various industries due to its versatile properties. It serves as a vital ingredient in the manufacturing of paper, paints, plastics, rubber, ceramics, and many other products. Its unique characteristics, including high whiteness, chemical stability, and low oil absorption, make it an ideal choice for a wide range of applications.

Case Study Description:

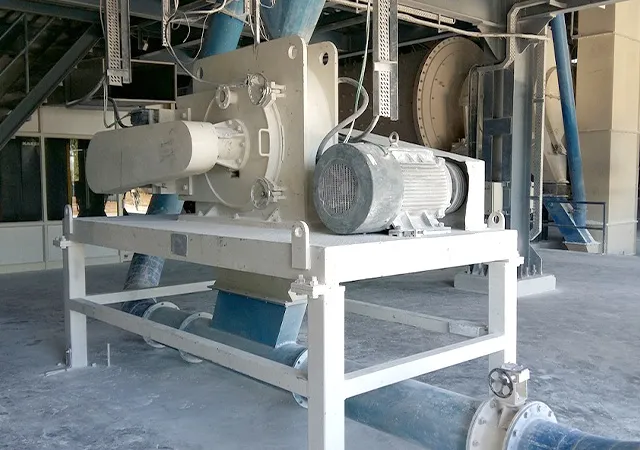

The chemical plant in Taiwan province has revolutionized its calcium carbonate production process by incorporating an ultrafine pin mill grinding production line. This cutting-edge technique utilizes a pin mill grinder to achieve ultrafine particle sizes, ensuring superior quality and enhanced performance of the final product.

The ultrafine pin mill grinding line has boosted calcium carbonate production at the chemical plant. The pin mill grinder crushes raw calcium carbonate into ultrafine particles. This process boosts dispersion and increases surface area. This leads to better product performance. For example, paints have increased opacity, papers show improved gloss, and plastics gain strength.

calcium carbonate ultrafine pin mill grinding related parameters

Materials:

Calcium carbonate

Granularity:

D90:4μm

Output:

2t/h