ModifiedStarch and ACM Grinding: Key to Enhancing Food and Industrial Applications

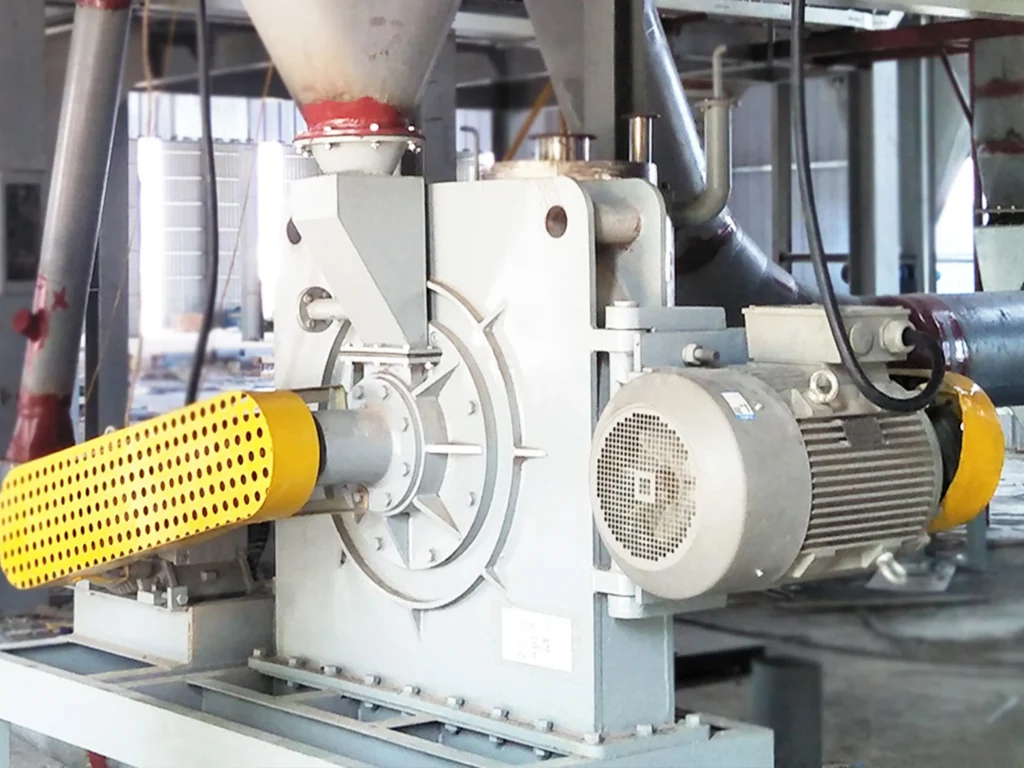

Starch, a crucial natural polysaccharide, is widely used in food processing, papermaking, textiles, pharmaceuticals, and chemicals. However, traditional starch often cannot meet the physical and