In the research and application of lithium batteries, selecting and designing anode materials is crucial for enhancing battery performance. Among these materials, porous carbon has gained widespread attention. This is due to its excellent electrochemical properties, good conductivity, and adjustable pore structure. This article will explore the significant role of the “small pores” in porous carbon materials. It will also discuss how controlling pore volume can improve the performance of lithium batteries.

Overview of Porous Carbon Materials

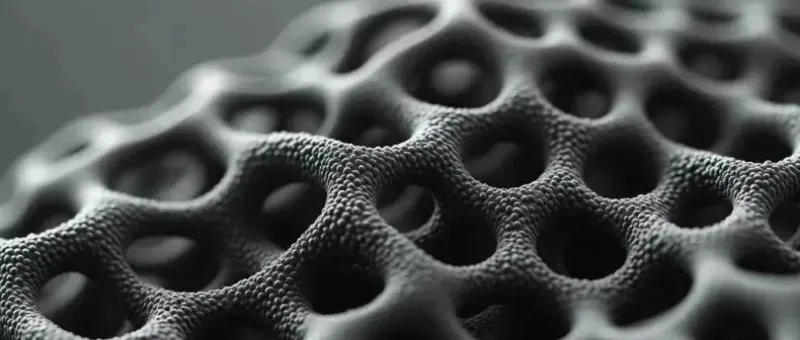

Porous carbon materials are carbon materials with numerous pores. These pores can vary in size and distribution, which determines their performance in battery applications. Based on pore size, porous carbons are classified into three categories: micropores (pore diameter less than 2 nm), mesopores (2 nm to 50 nm), and macropores (greater than 50 nm). These pore structures increase the material’s specific surface area and enhance the adsorption of electrolytes, providing enough space for the insertion and extraction of lithium ions.

The Role of Pore Volume

Pore volume refers to the total volume of all the pores in the material, directly affecting the lithium storage capacity of the anode. During charge and discharge cycles, lithium ions need to “insert” and “extract” within the anode material. The size of pore volume directly influences the reversible storage and transport efficiency of lithium ions. Porous carbon materials provide more lithium storage space through their large pore volume, enhancing battery capacity and cycling stability.

Pore Volume and Energy Storage Performance

Larger pore volumes allow more lithium ions to embed into the carbon material, increasing battery capacity. However, more pore volume is not always better. If the pore volume is too large, it can lead to uneven diffusion of lithium ions, affecting charge and discharge efficiency. Therefore, the pore volume needs to be precisely controlled when designing porous carbon materials to achieve optimal energy storage performance.

Pore Volume and Conductivity

An increase in pore volume typically accompanies an increase in specific surface area, which, in turn, improves material conductivity. Conductivity is crucial for high-power performance in lithium batteries. During fast charge and discharge, the electrode material must have good conductivity to enable rapid charge transfer. Pore volume adjustment can effectively enhance this property.

In-depth Analysis of Pore Volume Classification and Functional Differences

The pore volume of porous carbon can be classified into three categories based on pore diameter, each with distinct functions:

- Micropores (<2 nm):

Specific surface area can reach 2500 m²/g (e.g., activated carbon), with a theoretical lithium storage capacity of 372 mAh/g (1.1 times that of graphite).

Drawback: Mechanical stress (>50 MPa) generated during silicon particle expansion can lead to pore wall fracture.

Recent Progress: Introducing wrinkle structures into micropore walls through CO₂ activation increases compressive strength by 3 times. - Mesopores (2-50 nm):

The optimal pore diameter is about 1.5 times the diameter of silicon particles (e.g., 20 nm pores for 12 nm silicon particles).

Experimental Data: Mesoporous carbon with 50% silicon composite electrode maintains 89.6% first-cycle efficiency and 92% capacity retention after 500 cycles.

Innovative Application: A “core-shell” structure design reserves 30% expansion space. - Macropores (>50 nm):

These serve as highways for ion transport, reducing electrode impedance by 40%.

Drawback: Each 100 m²/g increase in specific surface area results in a 0.05 g/cm³ decrease in electrode density.

The Impact of Pore Structure on Battery Performance

Beyond pore volume, pore structure and distribution also significantly impact battery performance. For example, uniformly distributed small pores can promote rapid insertion and extraction of lithium ions, while large pores help improve the overall pore volume. During the preparation of porous carbon materials, adjusting the pore size, shape, and distribution allows precise control over lithium battery performance.

Pore Structure and Battery Cycling Stability

The design of the pore structure in porous carbon materials affects not only the initial charge/discharge capacity but also the cycling stability of the battery. A well-designed pore structure can mitigate volume expansion during long-term use, slowing material degradation, and enhancing cycling stability. Especially during high-rate charge/discharge, a good pore structure can alleviate electrode material pulverization, maintaining long-term battery performance.

Conclusion

The tiny pores hold enormous potential. These microscopic structures give porous carbon materials their unique advantages. In future battery technologies, how to precisely design and control pore volume and structure will be key to enhancing battery performance. As materials science continues to advance, porous carbon materials will continue to play a crucial role in high-efficiency energy storage technologies, providing more stable and durable energy support for the future of renewable energy.