Porous carbon has a high specific surface area, excellent conductivity, and chemical stability. It is widely used in energy storage, catalysis, adsorption, and electrochemical applications. However, powder agglomeration is a common and challenging issue during its preparation and application. To achieve uniform particle size distribution, better dispersion, and enhanced performance, Pin Mill (needle mill) dispersing technology has become a key solution in the post-processing of porous carbon.

Why is it Necessary to Disperse Porous Carbon?

After synthesis, porous carbon materials often exist in block or strongly agglomerated powder forms due to:

- High surface energy from the large specific surface area causing particles to attract each other;

- Agglomeration during drying or thermal treatment processes;

- Electrostatic forces and van der Waals forces.

Agglomerated porous carbon not only affects the material’s flowability and dispersion but may also cause partial collapse of the pore structure and reduction in specific surface area, ultimately impacting its performance in applications like lithium-ion batteries, capacitors, and catalysts. Therefore, precise and gentle dispersing becomes a crucial step in improving the material’s performance.

How Does the Pin Mill Work?

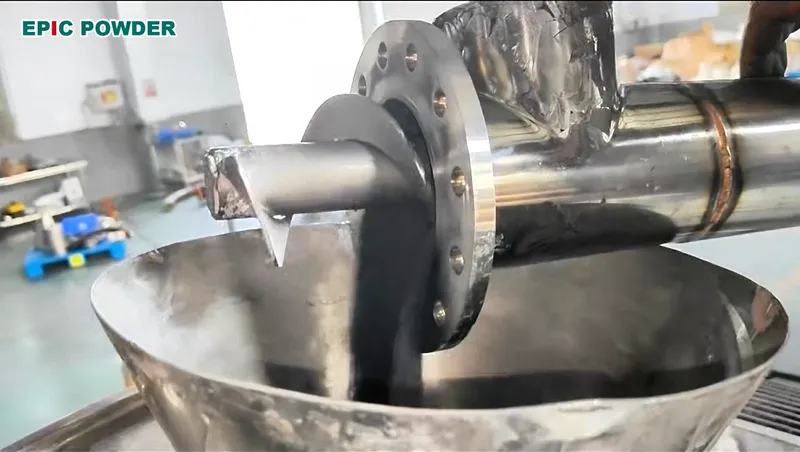

The Pin Mill is a fine grinding device that achieves particle size reduction through high-speed rotating pin plates. The core structure includes two sets of pin plates arranged oppositely, with one or both rotating at high speed, creating a strong airflow and shear force field.

In the grinding of porous carbon, the Pin Mill mainly achieves the following effects:

- Impact force: Breaks weak agglomerates and causes particle separation;

- Shear force: Mildly grinds the particle surface without damaging the pore structure;

- Airflow dispersion: Forms a uniform air-solid flow to prevent secondary agglomeration.

Compared to traditional ball mills or vibration mills, the Pin Mill offers a gentler and more controllable grinding process, making it ideal for preserving the original pore structure and specific surface area of porous carbon.

Advantages of Pin Mill Dispersing

Maintains Pore Structure Integrity

The energy input of the Pin Mill is relatively focused, and the momentary impact is brief, preventing the collapse of pore structures that could occur with long-duration high-energy grinding.

Efficient Dispersion and Uniform Particle Size Distribution

The system has adjustable rotational speed and airflow. It can precisely control grinding intensity. This achieves a concentrated particle size distribution and uniform particle morphology.

Low Contamination and Low Temperature

By using air as the medium for high-speed impact, the temperature rise is limited, making it suitable for heat-sensitive carbon materials.

Suitable for Continuous and Large-Scale Production

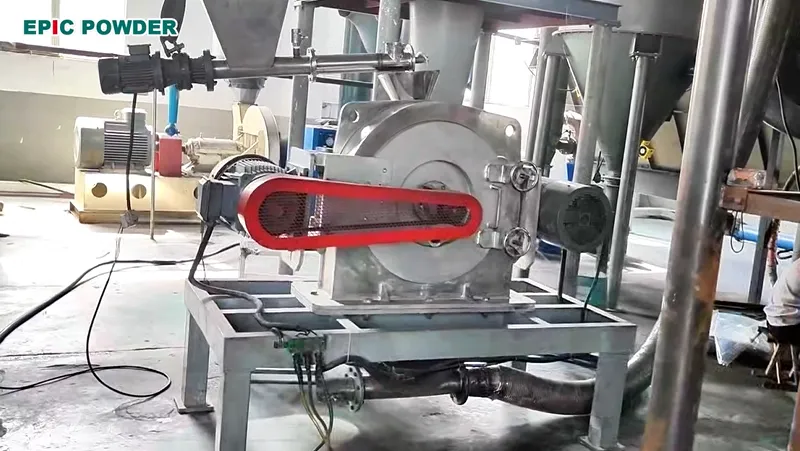

The Pin Mill can be integrated with air classifiers and dust collection systems to form a complete closed-circuit grinding production line, enabling stable, efficient, and automated production.

EPIC Powder‘s Porous Carbon Pin Mill Grinding System

With over 20 years of powder engineering experience, EPIC Powder has developed a dedicated Pin Mill dispersing system tailored for porous carbon, activated carbon, graphene, and other light agglomerative materials.

Key features of this system include:

- Precise energy control: Ensures complete dispersion without damaging the pore structure;

- Adjustable pin plate design: Adapts to different particle sizes and agglomeration strengths;

- Integrated classification and collection system: Prevents over-grinding and secondary agglomeration;

- Low-temperature operation and metal-free design: Meets the strict requirements for electrochemical and high-purity materials.

In practical applications, EPIC’s porous carbon grinding system has helped customers achieve:

- A reduction in particle size from d50 25 μm → 10 μm;

- A 98% retention of specific surface area;

- Significant improvements in powder flowability and dispersion.

Conclusion

The Pin Mill dispersing technology provides an efficient, controllable, and structure-friendly solution for the post-processing of porous carbon. By adjusting energy input and classification parameters, the technology ensures thorough agglomerate breakdown and uniform dispersion. It also maintains the integrity of the pore structure. With advanced powder engineering technology and extensive application experience, EPIC Powder’s porous carbon Pin Mill dispersing system is an essential tool. It enhances the performance and value of materials in energy, catalysis, and adsorption industries.