Gum arabic (Gum arabi, Acacia senegal, Acacia seyal), also known as Sudan gum, acacia gum, Senegal gum, and Indian gum, is an exudate from the trunks of trees in the genus Acacia of the legume family. It is also called acacia gum (legume family, Acacia genus). It is mainly distributed in Pakistan, Taiwan, tropical Africa, Arabia, and India, and has been artificially introduced and cultivated.

Gum arabic primarily consists of high-molecular polysaccharides and their salts of calcium, magnesium, and potassium. The main components include arabinose, galactose, and glucuronic acid. It is a harmless thickening agent that naturally solidifies in the air into tree gum. The gum is pale white to light yellow-brown, semi-transparent, in block form, or in white to orange-brown granular or powder form. It has a molecular weight of 220,000 to 300,000 and is a high-molecular electrolyte. It is odorless, tasteless, and flammable.

Growth and Process of Gum Arabic

Gum Arabic Growing and Harvesting

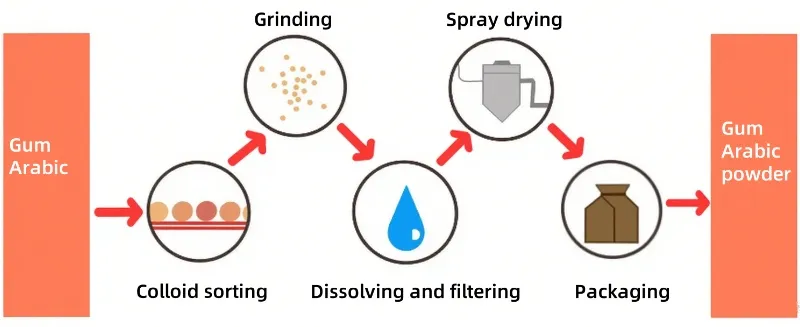

Gum Arabic Production Process

Gum Arabic Properties

Solubility

Soluble acacia senegal dissolves slowly at room temperature. As the temperature increases, the dissolution speed accelerates until it is completely dissolved. When cooled to room temperature, it remains stable, without gelation or precipitation. It has high solubility in water and relatively low solution viscosity. It can easily dissolve in both cold and hot water, and a 50% concentration solution still remains fluid. This is one feature that other hydrophilic colloids lack. However, it is insoluble in organic solvents like ethanol.

Stability

Acid Stability: Arabic gum has acidic groups in its structure. Its natural pH is weakly acidic. The pH range of 4-8 does not significantly affect its properties, making it stable in acidic environments.

Emulsifying Stability: Acacia senegal contains some proteins and rhamnose on its outer structure, which gives it excellent hydrophilic-lipophilic balance. This makes it a very good emulsifying agent for water-in-oil emulsions.

Heat Stability: Heating the gum solution generally does not alter its properties. However, prolonged high-temperature heating can cause the gum molecules to degrade, reducing its emulsifying performance.

Viscosity

The viscosity of gum arabic varies in different environments. It is mainly influenced by factors such as the source of the material, temperature, pH, and salt content.

Temperature: At temperatures ranging from 25 to 80°C, the viscosity of acacia senegal decreases as the temperature increases. The decrease is rapid between 30 to 70°C, and slows down after 70°C.

pH and Salt: The viscosity of acacia senegal is affected by pH and sodium chloride concentration. pH influences the dissociation of the carboxylic acids on the molecular chain, affecting its viscosity.

- Below pH 2.5 (when the acid is undissociated) and above pH 10 (where sodium ions shield the carboxylic acids, causing the molecules to fold), viscosity decreases.

- Between pH 2.5 and 10, as dissociation increases, repulsion between charged groups and the expansion of folded molecules lead to an increase in viscosity.

Emulsification

Arabic gum can also act as an emulsifier. Its emulsifying effect is mainly due to the strong cohesive force and elasticity of the interfacial membrane it forms. Its film-forming properties help prevent oxidation in capsule products, as well as prevent fats and moisture from separating.

Fragrance Retention

As a fragrance fixative, acacia senegal forms a protective film around the fragrance particles. This prevents oxidation and evaporation of the fragrance. It also prevents the fragrance from absorbing moisture from the air. With the development of advanced microencapsulation technologies, acacia senegal has found broader applications in fragrance retention.

Market Application of Gum Arabic

Application in Flavorings, Fragrances, and Encapsulation Powders

Arabic gum has the following advantages in flavorings, fragrances, and encapsulation powders:

- Ensures better encapsulation of oil droplets (essential oils, oleoresins, vitamins, fragrances, colorants).

- Increases stability by protecting powders from moisture, preventing the release of essential oils, volatile compound loss, and oxidation.

- Acts as an effective neutral binder.

Application in Frozen Foods

In frozen foods, such as ice cream and non-dairy frozen desserts. Arabic gum is used as a stabilizer. Arabic gum has strong water-absorbing properties, binding large amounts of water. The hydrated form of acacia senegal keeps moisture inside, forming a finer structure within ice cream and preventing the formation of ice crystals.

Application in Beverages

Arabic gum is used as a foam stabilizer in beverages like beer. It gives beverages, such as fruit juices, an appealing cloudy appearance. In carbonated drinks. acacia senegal is used for emulsifying and dispersing flavors and colors, preventing color rings at the bottle neck. It is also used as a clouding agent in drinks and stabilizing beer foam.

Application in Bakery Products

Arabic gum is widely used in the bread industry due to its viscosity and adhesive properties. It gives a smooth finish to the surface of bread.

Application in Confectionery Products

Acacia senegal is extensively used in candy manufacturing due to its ability to prevent sugar crystallization. It also thickens and intensifies. It acts as an anti-crystallizing agent in candy, preventing sucrose crystallization. It emulsifies milk fat in milk candies to prevent spillage. Arabic gum is also used to glaze chocolate surfaces, ensuring it melts in the mouth, not the hand. This edible gum is used in transparent candy coatings, chewing gums, and diamond-shaped candies. Gumdrops are made from Arabic gum.

Application in Snacks

Arabic gum offers the following benefits in snacks:

- Forms a protective outer film.

- Helps evenly distribute salt, herbs, or spices.

- Acts as a binder, improving the cohesion and stability of grains.

- Extends product shelf life.

Application in Pet Treats and Instant Noodles

Arabic gum is used in pet treats and instant noodles for the following reasons:

- Increases the viscosity of mixtures.

- Enhances taste and appetite.

- Improves the texture of noodles after rehydration.

- Enhances thermoplasticity and lubricity.

Epic Powder

Epic Powder’s advanced powder processing technologies, including grinding, classifying, and surface modification equipment, play a crucial role in optimizing the functionality of Arabic gum in various industries. By leveraging our precision equipment, we ensure consistent powder quality. Whether it’s enhancing stability in food products or improving emulsification in beverages, Epic Powder’s solutions provide the perfect synergy to meet the evolving demands of the market. Our expertise in fine powder processing guarantees that Arabic gum retains its superior performance, providing manufacturers with reliable, high-quality ingredients for diverse applications.