Silicon is the second most abundant element on Earth, after oxygen. Its abundance and low cost make it one of the most readily available inorganic materials. In contemporary technological developments, nanomaterialization can significantly improve silicon’s various properties. This has broad potential for applications in silicon-based anode materials, photovoltaic cells, luminescence, biomedicine, and other fields. Nano-silicon refers to silicon particles on the nanoscale. Nano-silicon powder features high purity, small particle size, and uniform distribution. It also has a large surface area, high surface activity, and low bulk density. The product is non-toxic and odorless. At present, the main methods for preparing nano-silicon powder include mechanical ball milling, chemical vapor deposition (CVD), and plasma evaporation condensation.

Mechanical Ball Milling Method

This method involves mechanical rotation and particle interaction. This generates mechanical grinding pressure and shear force. It grinds larger silicon materials into nano-sized powder. The process typically uses wet sand milling combined with spray drying. Grinding aids are added during the grinding process. Post-treatment procedures are also required. The resulting nano-silicon particles are around 100 nm in size. This can be further reduced to 75-80 nm. Industry experts believe that, before the silicon-carbon anode material volume increase period arrives, optimizing the process chain and equipment in the ball milling process will be key. This will help achieve the best balance between product performance and cost.

Chemical Vapor Deposition Method

Chemical vapor deposition (CVD) uses silane (SiH4) as the reaction material. It is used to produce nano-silicon powder. Depending on the energy source used to induce SiH4 pyrolysis, CVD can be divided into plasma-enhanced chemical vapor deposition (PECVD), laser-induced chemical vapor deposition (LICVD), and fluidized bed reactors (FBR). Among these, PECVD and LICVD are the most widely used industrial production technologies for nano-silicon powder.

Plasma Evaporation Condensation Method

This method has been used in the past decade to produce high-purity, ultra-fine, spherical, and high-value-added powders. It is a safe and efficient method. Plasma heat sources are used to vaporize the raw material into gaseous atoms, molecules, or partially ionized ions. Then, they are rapidly condensed into solid powder. This method is suitable for preparing various metal nanomaterials. It is also ideal for carbide and nitride nanomaterials. The nano-silicon powder produced by this method has high purity, controllable particle size, and high production efficiency. It is the mainstream technology used by leading foreign manufacturers. However, its introduction in China has been relatively late. Research in this area is still in its early stages. Challenges remain in areas such as fundamental theoretical research and nanoparticle performance studies. Issues related to yield and production rate also remain. High-performance nano-silicon powder production has yet to be fully independently controlled in China.

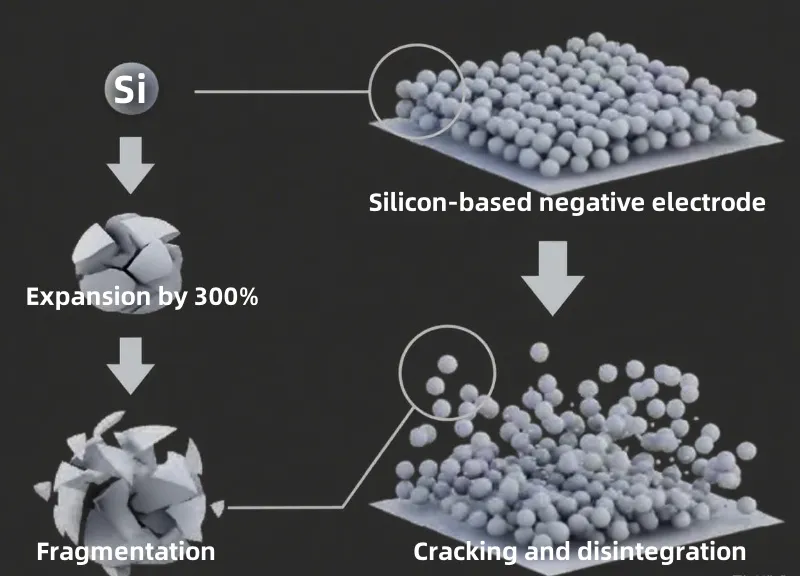

Silicon-Based Anode Materials

In recent years, the rapid development of lithium batteries has placed a focus on silicon anode materials. Silicon anode materials are an essential component for next-generation high-energy-density lithium batteries. However, silicon undergoes significant volume expansion during lithiation. This expansion requires optimization of the active material to maintain reversible alloying and de-alloying processes. This optimization prevents fragmentation or degradation of the active material. Therefore, nano-structuring silicon anodes can achieve long-term stability in performance. This is in contrast to traditional micron-sized silicon anodes.

Photovoltaic Cell Field

Nano-silicon is used in the production of second-generation silicon-based thin-film photovoltaic cells. Specifically, it is used in microcrystalline silicon thin-film cells. Nano-silicon-based thin-film cell technology has unique advantages over other second-generation silicon-based technologies. However, the preparation of nano-silicon and its application in photovoltaic cells are still immature. Second-generation photovoltaic cells have a relatively low market share. They are not yet the mainstream technology.

High-purity nano-crystalline silicon is used to make silicon electronic paste. This paste is coated onto the surface of solar cell substrates. It enhances the conversion efficiency of silicon solar cells. This has become an important direction in the solar industry.

Lighting Field

By controlling the diameter of nano-silicon particles, a full-spectrum emission from blue to red light can be achieved. Additionally, electro-controlled electroluminescence can be supported.

Biomedicine Field

Due to its low toxicity and biocompatibility, silicon-based biomaterials have long played an indispensable role in biomedicine. Since 2001, mesoporous silicon nanoparticles have been ingeniously used as drug delivery carriers. Zero-dimensional silicon-based nanomaterials have seen extensive development in biomedical applications. For example, silicon quantum dots with good biocompatibility have been developed as novel biological imaging probes. This is inspired by the photoluminescent properties of semiconductor quantum dots caused by quantum confinement effects.

Other Applications

In addition to the applications mentioned above, nano-silicon is used to prepare high-power rectifiers, high-power transistors, diodes, switching devices, semiconductor discrete devices, power devices, integrated circuits, and epitaxial substrates. It is also used as raw material for high-temperature coatings and refractory, corrosion-resistant, and anti-static materials. Nano-silicon, when mixed under high pressure with diamonds, forms silicon carbide-diamond composite materials. These are used for cutting tools. Additionally, nano-silicon is used in the preparation of high-silicon cast iron, silicon steel, and various organosilicon compounds.

Epic Powder

The state-of-the-art grinding solutions of Epic Powder are at the forefront of the nano-silicon production process. By integrating high-performance equipment such as ball mills and air classifiers, Epic Powder ensures the precision required to produce nano-silicon with optimal particle size distribution and purity. Whether for use in advanced lithium battery anodes, photovoltaic cells, or biomedical applications, Epic Powder’s customized grinding equipment can help maximize production efficiency while minimizing energy consumption. Through continuous research and development, Epic Powder contributes to the global advancement of nano-silicon applications. The company offers essential support in achieving the best performance at cost-effective prices.