In the era of rapid growth in new energy vehicles and energy storage technology, lithium-ion batteries—serving as the core power source—are pivotal to the industry’s future. As the “star player” among cathode materials, Lithium Nickel Cobalt Manganese Oxide (NCM) has become the first choice for electric vehicles and high-end consumer electronics, thanks to its high energy density, long cycle life, and cost advantages.

Lithium Nickel Cobalt Manganese Oxide (NCM) Materials: Why It’s the “Heart” of Lithium-Ion Batteries

NCM (LiNiₓCoᵧMn₁₋ₓ₋ᵧO₂) is a layered ternary oxide material with key advantages:

- High Energy Density – By adjusting the ratio of nickel (Ni), cobalt (Co), and manganese (Mn) (e.g., NCM523, NCM622, NCM811), the capacity and stability of the material can be precisely controlled.

- Cost Optimization – Manganese is abundant and reduces cobalt usage, effectively lowering material costs.

- Safety Balance – Manganese enhances thermal stability, reducing safety risks under overcharge or high-temperature conditions.

Applications: Electric vehicles, 3C electronics, home energy storage systems, and more.

Full NCM Synthesis Process: Transformation from Atoms to Electrodes

Raw Material Preparation: Precision Ratio is Key

- Metal Salts: Sulfates, nitrates, or chlorides of Ni, Co, Mn (industrial-grade purity ≥99%).

- Lithium Sources: Lithium hydroxide (LiOH·H₂O) or lithium carbonate (Li₂CO₃) with strict particle size and impurity control.

- Solvents & Additives: Deionized water, ammonia solution (pH adjustment), and surfactants (to prevent agglomeration).

Key Point: The molar ratio of raw materials directly impacts the final chemical stoichiometry and must be verified with ICP-OES or similar instruments.

Co-Precipitation: Creating a Nano-Scale Precursor

Steps:

- Prepare Mixed Salt Solution: Dissolve Ni, Co, Mn salts in the required proportions.

- Reactor Precipitation: Under nitrogen protection, feed the salt solution and NaOH/ammonia mixture into a reactor. Control pH (10–12), temperature (50–60°C), and stirring speed to produce spherical hydroxide co-precipitate NiₓCoᵧMn₁₋ₓ₋ᵧ(OH)₂.

- Washing & Drying: Wash thoroughly with deionized water, then dry at 120°C.

Technical Challenges:

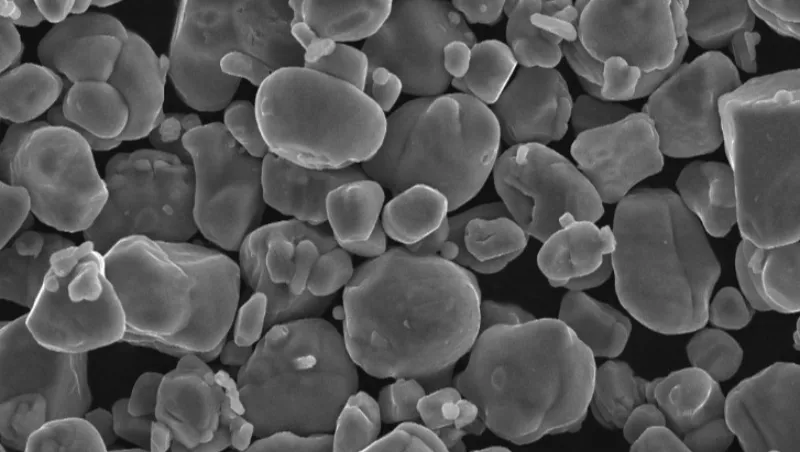

- Controlling particle size distribution (D50: 5–15 μm).

- Optimizing sphericity (affects coating uniformity in later steps).

High-Temperature Solid-State Reaction: Lithiation and Crystallization

Steps:

- Mixing & Milling: Combine precursor and lithium source in stoichiometric ratio, add flux (e.g., LiF), ball mill to <1 μm.

- Pre-Sintering: Heat in oxygen atmosphere at 500–600°C for 4–8 hours to remove water and organics.

- High-Temperature Sintering: Ramp to 750–1000°C in stages, hold for 10–20 hours for lithiation and layered structure formation.

- Grinding & Sieving: Use jet milling to reach D50 = 3–8 μm, sieve to remove oversized particles.

Process Comparison:

- Traditional Solid-State Method: Low cost, uneven particle size.

- Sol-Gel Method: Uniform particle size, complex process, high cost.

Surface Modification: “Black Technology” for Longer Cycle Life

- Coating Technology: Use ALD (Atomic Layer Deposition) or wet-chemical methods to coat Al₂O₃, ZrO₂, etc., to prevent electrolyte corrosion.

- Doping Modification: Introduce Al, Mg, and other elements to stabilize crystal structure and reduce phase transitions.

Performance Results: Coated NCM materials can maintain capacity retention above 90% after 500 cycles at 45°C (compared to 80% without coating).

Future Trends

High-Nickel NCM: Moving from NCM811 to NCM9½½, pushing energy density above 300 Wh/kg.

Single-Crystal NCM: Controlling sintering conditions to produce single-crystal NCM, reducing particle fracture and side reactions.

Cobalt-Free Materials: Developing lithium-rich manganese-based materials (LMR) to eliminate dependence on cobalt.

Epic Powder

With over 20 years of expertise in ultra-fine grinding and classification, Epic Powder provides advanced milling, classification, and surface modification equipment tailored for Lithium Nickel Cobalt Manganese Oxide (NCM) :cathode material production. From precise precursor grinding to controlled particle shaping, Epic Powder ensures consistent particle size distribution, optimized surface properties, and enhanced electrochemical performance—helping battery manufacturers achieve higher energy density, longer cycle life, and greater production efficiency.