Ultra-Fine Grinding is a cornerstone technology in modern manufacturing, critical to sectors like chemicals, pharmaceuticals, and food production. However, it faces unique challenges when applied to Heat-Sensitive Materials, such as certain drugs, food additives, fragrances, and polymers. These materials are prone to undesirable physical, chemical, or biological changes at elevated temperatures. Consequently, the specialized field of ultra-fine grinding of heat-sensitive materials has emerged as a vital discipline, essential for preserving the quality and integrity of the final product.

Characteristics of Heat-Sensitive Materials

Heat-sensitive materials typically have the following characteristics:

- Easily Decomposed: Many heat-sensitive materials decompose or degrade at high temperatures, leading to the loss of active components.

- High Chemical Reactivity: Some chemical components may change at elevated temperatures, affecting their stability.

- Volatility: Some heat-sensitive materials, such as fragrances and pharmaceutical, are highly volatile and may evaporate under high temperatures.

- Stickiness: Some heat-sensitive materials tend to adhere to equipment during grinding, causing material loss or equipment blockages.

The Impact of Ultra-Fine Grinding on Heat-Sensitive Materials

In the ultra-fine grinding of heat-sensitive materials, temperature increase is a key issue. High temperatures not only cause a reduction in the material’s quality but also make the production process unstable. Common issues include:

- Heat Accumulation: Traditional grinding equipment, such as ball mills and vibration mills, often generate significant heat during grinding, leading to excessive heating of materials.

- Material Loss: Heat-sensitive materials may evaporate or degrade due to high temperatures during grinding, leading to a loss of active ingredients and reduced product quality.

- Increased Equipment Wear: High temperatures may cause materials to stick to equipment surfaces, increasing wear and maintenance costs.

Ultra-Fine Grinding Technologies for Heat-Sensitive Materials

To address the characteristics of heat-sensitive materials, modern grinding technology has developed several effective solutions aimed at reducing temperature rise and maintaining the material’s original quality. Here are some common technologies:

Air Jet Mill Technology

The jet mill is a common ultrafine grinding device. It uses high-speed airflow to create intense collisions within the grinding chamber, achieving pulverization. The main advantage of a jet mill is that it generates virtually no external heat during the pulverization process, resulting in minimal temperature rise in the material. This makes it ideal for ultrafine grinding of heat-sensitive materials. Furthermore, jet mills achieve high dispersion and a narrow particle size distribution, meeting stringent process requirements.

Cryogenic Grinding

Cryogenic milling technology uses cooling gas or liquid nitrogen to lower the material temperature during the milling process. This prevents material deterioration or degradation caused by high temperatures. Cryogenic milling is often used in industries where material properties (such as active ingredients and fragrances) must be preserved. It is particularly suitable for heat-sensitive pharmaceuticals and natural extracts.

Wet Milling

Wet milling involves mixing the material with a liquid (such as a solvent or water) before milling to lower the material temperature and protect it from the effects of high temperatures. Wet milling is generally effective in minimizing the loss of volatile components in heat-sensitive materials. It is particularly suitable for milling materials that are sensitive to humidity.

Cooling System Design

In addition to choosing the right grinding equipment, a well-designed cooling system is crucial to protect heat-sensitive materials. By enhancing the cooling system of the equipment, the heat generated during grinding can be minimized, reducing the thermal damage to the material.

Applications of Ultra-Fine Grinding for Heat-Sensitive Materials

- The ultra-fine grinding technology for heat-sensitive materials has wide applications in industries that require strict quality control. Major application areas include:

- Pharmaceutical Industry: Ultra-fine grinding of pharmaceutical not only improves their dissolution rate but also enhances their bioavailability. Many pharmaceutical ingredients are highly temperature-sensitive, and air jet mills or cryogenic grinding technologies can effectively preserve their activity.

- Food Industry: Many food additives, fragrances, and natural extracts are heat-sensitive. Ultra-fine grinding improves their dispersion in food products while preventing temperature-related degradation of flavor and nutritional value.

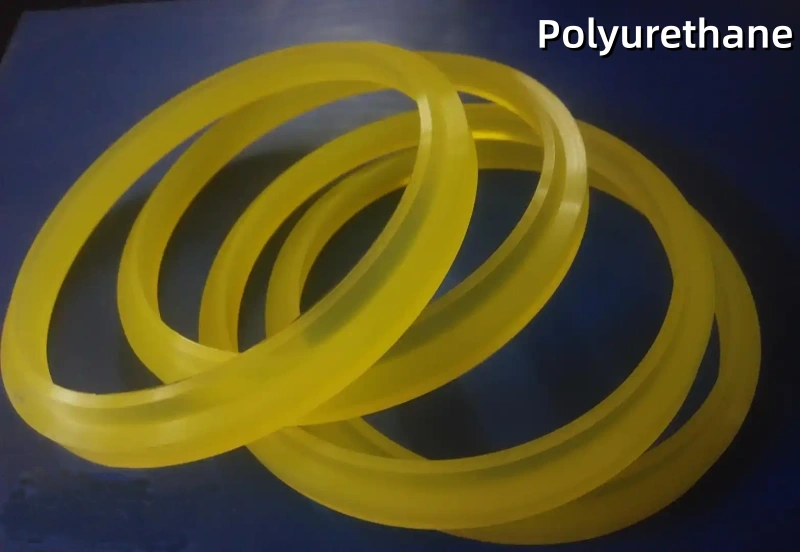

- Chemical Industry: In the chemical industry, ultra-fine grinding enhances the reactivity and dispersion of certain materials. Heat-sensitive raw materials, such as specific polymers or synthetic resins, need precise temperature control during grinding.

- Environmental Protection Industry: Some materials used in environmental protection, such as high-performance filtration media or catalysts, are also heat-sensitive, and ultra-fine grinding improves their efficiency.

Conclusion

The ultra-fine grinding of heat-sensitive materials plays a critical role in modern high-value industries. To efficiently address the challenge of material degradation due to heat generated during the milling process, key industry techniques include jet milling and cryogenic grinding. Taking EPIC Powder Equipment as an example, their advanced Fluidized Bed Opposed Jet Mills (such as the MQW series) are an ideal choice for processing heat-sensitive and low-melting point materials. This is due to their design, which eliminates mechanical friction heat, utilizes the cooling effect of expanding gas, and offers optional inert gas protection. As technology continues to advance, specialized powder solution providers (like EPIC Powder) will further refine ultra-fine grinding techniques for heat-sensitive materials, delivering more stable and optimized solutions to relevant industries.