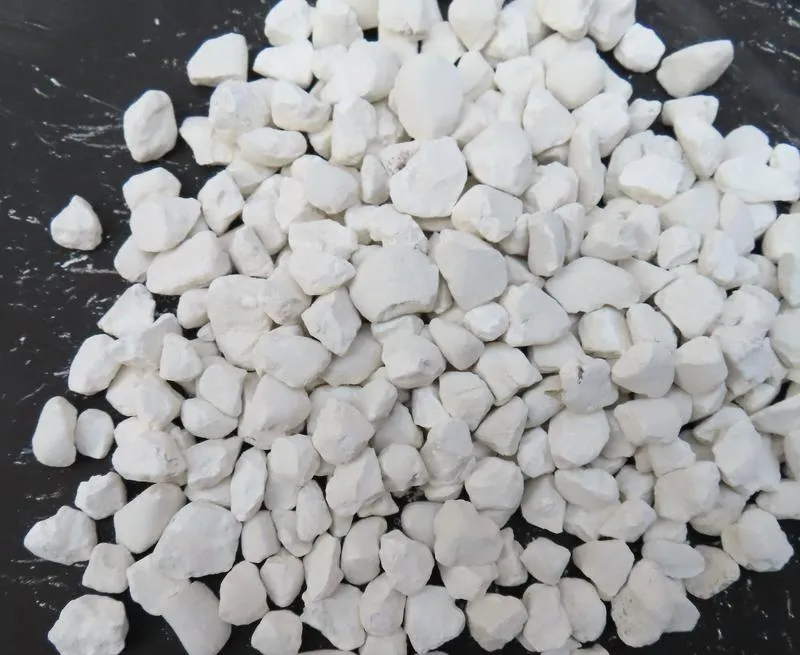

Deep-processed lime differs from ordinary metallurgical and road lime. For deep processing lime, the higher the calcium oxide content, the better, while the content of silicon, magnesium, and other heavy metals should be as low as possible. This is because the calcium oxide content is the main factor determining the product price. The calcination process for deep-processed lime differs from that of ordinary lime. The output and energy consumption vary greatly, but the cost increase is minimal. High-calcium limestone has a relatively low calcination cost, and the processed products will have a higher price. Generally, the calcium content of the limestone for deep processing should be above 54%.

Calcination Process Requirements for Deep-Processed Lime

In the calcination process, a higher degree of over-burning (slightly older) is required, so the quality of the raw limestone and processing requirements are particularly high. Specifically:

- Limestone block size must be uniform.

- Silicon content should not be too high.

- Limestone should preferably be washed to remove mud and sand.

- Coal must have low volatile powder content.

- Calcination should be dynamically operated.

Deep-processed lime must be evenly over-burned, and the under-burned portion should be minimal. Achieving the above five points ensures the product’s calcium oxide content is as high as possible. High-end lime products must come from good limestone ore, good calcination, and deep processing to provide higher added value.

How to Produce High-Calcium Oxide

Calcium oxide has wide applications in industries such as steel, pesticides, pharmaceuticals, food, leather, and chemicals. The primary equipment used for production includes ball mills, ultrafine mills, Raymond mills, vertical mills, air flow mills, and kilns. Each of these grinding devices has its unique characteristics. The choice of equipment depends on the main products of the enterprise and market positioning.

Ball Mill

Suitable for rough calcium oxide products below 200 mesh. The device is characterized by high output, low wear, and simple operation. However, it requires a large area, has high costs, and generates excessive noise, making it unsuitable for some environmental regulations.

Ring-Roller Ultrafine Mill

Suitable for general ultrafine calcium oxide grinding, with fineness between 800 and 1200 mesh. The equipment has low single-machine output and is suitable for general deep processing needs.

Raymond Mill

This is a coarse grinding device with the best cost-performance ratio among many options. It has the following advantages:

- High Reliability: New technologies, such as plum frame and vertical swinging roller devices, offer a rational structure. The machine’s vibration is minimal, noise is low, and operation is stable and reliable. It has proven beneficial in both social and economic terms through market application.

- High Efficiency and Energy Savings: The material’s processing amount per unit grinding time is larger, making it more efficient. In comparison with the R-type mill of the same power, its output increases by more than 40%, while energy consumption is reduced by over 30%.

- Environmental Friendliness: The mill’s exhaust is equipped with a pulse dust collector with a dust collection efficiency of 99.9%. The main parts of the machine are sealed, resulting in essentially dust-free operations in the workshop.

Vertical Mill

The vertical mill is ideal for large-scale calcium oxide grinding, handling both coarse and ultrafine powders, with fineness between 200 mesh and 2500 mesh. It has a high cost, large investment, and low maintenance. Typically, larger enterprises opt for this equipment. Its advantages include:

- Low Comprehensive Investment Costs: It integrates crushing, drying, grinding, classification, and transportation into one system. The process flow is simple, and the system has fewer devices and a compact layout, occupying only 50% of the area of a ball mill.

- High Grinding Efficiency: The mill is more energy-efficient, with a 40%-50% reduction in energy consumption compared to a ball mill. The large single-machine production capacity allows for the use of low-cost off-peak electricity.

- Easy Maintenance, Low Operating Costs: The grinding rollers can be hydraulically ejected for easy maintenance and replacement. The wear-resistant materials extend service life, and the mill can start without the need for pre-loading, solving startup difficulties.

- Stable Product Quality: The short retention time in the mill allows for precise control over product particle size and chemical composition, reducing over-grinding. The resulting product is uniform in particle shape, narrow in size distribution, and has excellent fluidity.

- High Reliability: The mill uses a roller positioning device to avoid vibrations caused by material interruptions. The new roller sealing system ensures reliable sealing without the need for a sealing fan, further reducing oxygen content and improving explosion suppression performance.

- Environmental Protection: The vertical mill operates with low vibrations and noise. The system is fully sealed and runs under negative pressure, effectively preventing dust leakage.

- High Automation: The system is controlled by a PLC, allowing for remote operation and reducing labor costs.

Epic Powder

Epic Powder, specializing in advanced grinding and powder processing equipment, offers solutions tailored to the production of high-calcium oxide. The company’s state-of-the-art ball mills, Raymond mills, and vertical mills provide efficient, reliable, and environmentally friendly options for deep processing of lime. With its experience and technology, Epic Powder can help businesses achieve higher product value and better performance in the lime industry.