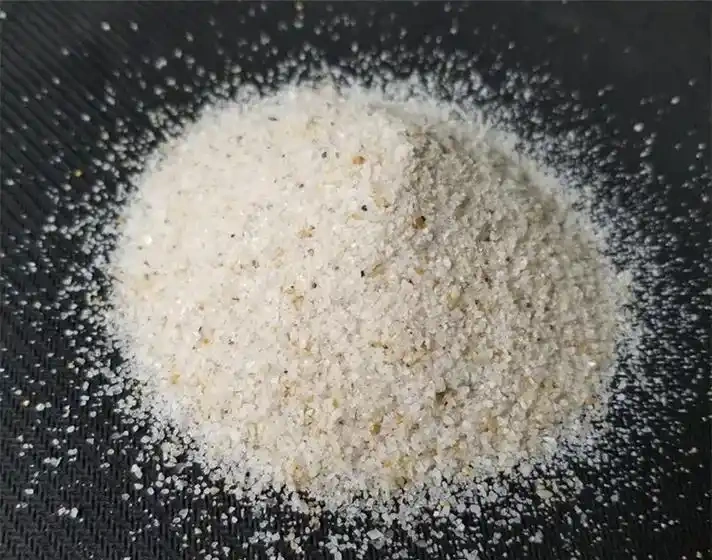

Quartz sand is an important basic non-metallic mineral resource, widely used in fields such as glass manufacturing, mechanical casting, electronics, metallurgy, refractory materials, chemicals, and ceramics.

Customers often ask which products their quartz ore is suitable for and which industries it can be applied to. Based on the silica (SiO2) content, a preliminary judgment can be made. Quartz sand can be divided into three categories based on SiO2 content:

Quartz sand with SiO2 content below 99.9%

This type of quartz sand is mainly used in large-volume industries, including:

- Flat glass production: Ordinary flat glass such as building glass and window glass.

- Casting and metallurgy industries: Used for foundry sand and furnace materials.

- Refractory materials: Provides heat resistance in high-temperature environments.

- Ceramics production: Used in making daily-use ceramics and construction ceramics.

- Building materials: Used in mortar, concrete, and other applications.

These industries require lower purity and focus on physical characteristics like particle size, hardness, and color. The market supply is abundant, though transportation distance may limit raw material availability.

Quartz sand with SiO2 content between 99.9% and 99.99%

This purity range is used in high-end fields, including:

- Silica micropowder production: Essential for semiconductors, photovoltaics, and electronics.

- Photovoltaic glass: Critical for the production of solar panels.

- High-end glass: Used for optical glass and display screen glass with strict impurity requirements.

- Sodium silicate: Used as a raw material in chemical production.

For this quartz sand, controlling Fe, Al, and other impurities is crucial. Particle size is also important. The supply is influenced by ore processing technology, costs, and transportation, leading to a “tight balance” in the market.

Quartz sand with SiO2 content above 99.99%

This high-purity quartz sand is mainly used in:

- High-purity quartz glass: Required for high-precision electronic devices and medical equipment.

- High-purity silica micropowder: Used in semiconductor manufacturing, photovoltaics, and high-tech electronics.

These applications have very strict requirements. Impurities such as Al, Ti, K, Na, and Li must be controlled to the 10-6 level. Particle size and crystal lattice impurity content also affect product quality. Due to its scarcity, the supply of this high-purity quartz sands often fails to meet demand.

Factors Affecting the Processability

High-purity quartz sands production depends on more than just SiO2 content. Natural characteristics of the quartz minerals play a significant role. These include:

- Fluid inclusions: If the ore contains fluid inclusions, it may introduce impurities.

- Mineral inclusions: Other minerals, such as feldspar and mica, can affect product purity.

- Crystal lattice impurities: Elements like aluminum and iron within the quartz crystal structure can degrade product quality.

Specific Requirements for Quartz Sand in Different Industries

Quartz sands applications vary significantly across industries. Requirements for purity, particle size, and sphericity differ. Industries like electronics demand high purity, while construction materials focus more on physical properties and less on purity.

Conclusion

Quartz sand is a crucial resource used across various industries. Different industries have unique requirements for purity, particle size, and other characteristics. When choosing quartz ore, customers can start by looking at its SiO2 content. However, processing technology and the ore’s natural features also play important roles in determining its suitability for different applications. Understanding the physical and chemical properties of the ore is essential to meet industry-specific needs