Understanding Petroleum Coke Characteristics

Petroleum coke (petcoke) is a carbon-rich solid derived from the oil refining process. It features a high carbon content, low ash, and variable sulfur levels depending on the source crude. These characteristics make it valuable across industries, especially when processed into fine powders through petroleum coke ultrafine grinding, which enables precise particle size control, improved reactivity, and enhanced performance in applications such as fuels, electrodes, and advanced carbon materials.

Physical Properties and Grindability

Petcoke has a Mohs hardness typically ranging between 2.5 and 3.5, which classifies it as relatively soft compared to minerals but still tough enough to require specialized grinding technology. Its abrasive nature and irregular particle structure can cause significant wear on conventional mills, affecting overall grinding efficiency. This means traditional mechanical mills often struggle with size reduction, especially in producing ultrafine powders.

Why Ultrafine Grinding Matters

Ultrafine grinding of petroleum coke is crucial for meeting the demands of highly specialized applications, such as:

- Lithium-ion battery anode materials, where particle size and uniformity directly impact battery performance.

- Metallurgical processes, requiring consistent fine carbon raisers to enhance steel quality.

- The chemical industry, where superfine carbon powders serve as fillers or catalysts.

Achieving a D97 particle size distribution of 28 μm ensures optimal surface area, reactivity, and flow properties essential for these uses. Ultrafine grinding enhances these key attributes, improving the material’s performance and application consistency.

By truly understanding petroleum coke’s physical properties and grindability, we can appreciate why advanced ultrafine grinding technologies like the fluidized bed jet mill are indispensable in producing high-quality, superfine petcoke powders.

Why Traditional Milling Fails vs. Air Jet Milling

When it comes to ultrafine grinding of petroleum coke, traditional mechanical mills like ball mills and Raymond mills often fall short. These mills struggle to break down petroleum coke to the target D97 particle size distribution of 28 μm, mainly due to the material’s hardness and abrasive nature. Mechanical mills generate high friction and heat, which not only reduces grinding efficiency but also risks altering the coke’s chemical structure. Wear on grinding media and liners leads to contamination and increased maintenance costs.

In contrast, air jet milling is a game-changer for petroleum coke ultrafine grinding. It uses collision grinding, where particles hit each other at high speeds, effectively reducing size without mechanical contact. This process allows precise control of temperature, minimizing thermal damage and preserving material quality. The absence of grinding media also means much lower wear rates, improved contamination control, and reduced downtime.

Key advantages of air jet mills for petroleum coke ultrafine grinding include:

- Collision grinding for efficient, uniform particle size reduction

- Temperature control that prevents heat buildup and material degradation

- Minimal wear and contamination thanks to no physical grinding parts

- Flexible adjustment of grinding and classification parameters for target sizes

These benefits make air jet milling the preferred choice for producing superfine petroleum coke powder suitable for high-end applications like lithium-ion battery anodes and specialty carbon materials. For a deeper technical comparison, check out our detailed overview of jet milling advantages and disadvantages.

Technical Deep Dive: Achieving D97 28 μm

To reach a precise D97 particle size of 28 μm in petroleum coke ultrafine grinding, mastering the process flow is key. This includes feeding, grinding, and classification—each step directly impacts the final particle size distribution and quality of the superfine powder.

Process Flow Overview

| Step | Description | Key Control Factors |

|---|---|---|

| Feeding | Consistent material input to the mill. | Feed rate, material moisture, particle pre-size |

| Grinding | Ultrafine pulverization inside the mill. | Mill speed, nozzle design, grinding pressure |

| Classification | Separation of fine particles from coarse ones. | Classifier wheel speed, air flow, air pressure |

Controlling Cut Point

The cut point determines the max particle size passing through, crucial to hit the D97 target. Two main factors control it:

- Classifier Wheel Speed: Faster speeds produce finer powders by increasing centrifugal force to reject larger particles.

- Air Pressure: Higher air pressure aids particle suspension and enhances classification efficiency.

Managing Particle Size Distribution

Balancing variables ensures an even particle size distribution without excessive fines, which can cause handling problems:

- Monitor classifier wheel speed and air pressure closely.

- Adjust feed rate to prevent overloading.

- Use real-time particle size analyzers for feedback control.

By optimizing these parameters, ultrafine grinding of petroleum coke to a D97 of 28 μm is achievable with high efficiency and repeatability.

For more insights on how air classifiers improve ultrafine grinding, check out Epic Powder’s advanced industrial air classifier solutions. Additionally, exploring their graphite ultrafine powder production highlights process control examples closely related to petcoke micronization.

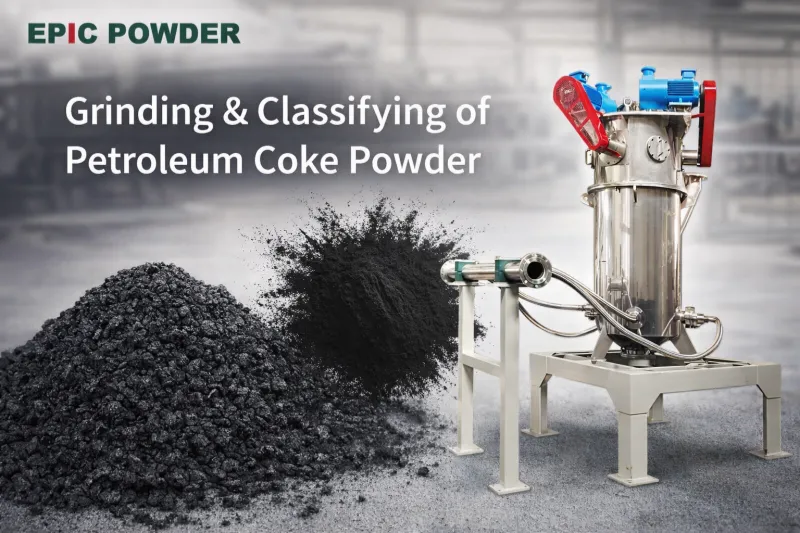

Epic Powder’s Solution: The Fluidized Bed Jet Mill

Epic Powder tackles the challenge of ultrafine grinding of petroleum coke with its advanced fluidized bed jet mill. This technology is designed for efficiency, precision, and durability to meet the demanding requirements of D97 28 μm particle size distribution.

Key Equipment Features

| Feature | Description |

|---|---|

| High Efficiency Nozzle Design | Optimizes collision grinding to break down petroleum coke effectively with less energy. |

| Smart Classification System | Uses a variable frequency classifier wheel allowing precise control of particle size cut point. |

| Wear Protection Linings | Made from ceramic materials to resist abrasion from hard coke particles, extending equipment life. |

| PLC Automation | Ensures stable operation with repeatable performance and easy process adjustments. |

These features collectively improve grinding efficiency, minimize downtime, and maintain consistent carbon powder micronization quality necessary for industrial uses such as anode material pulverization.

For a deeper look into energy-saving practices and automated control systems integrated with jet mill technology, the efficient upgrade of carbon black production line offers useful insights relevant to ultrafine grinding processes.

Epic Powder’s fluidized bed jet mill stands out for handling the unique hardness and physical properties of petroleum coke, ensuring smooth ultrafine grinding and stable output that fits high-demand industries perfectly.

Industrial Applications of Ultrafine Petroleum Coke

Ultrafine petroleum coke, ground to a D97 particle size of around 28 μm, plays a crucial role across several high-value industrial sectors. Its fine particle size and consistent quality make it ideal for demanding applications such as lithium-ion battery anode precursors. In this field, superfine petcoke powders are preferred because they deliver excellent conductivity and stability, essential for producing high-performance battery materials.

In metallurgy, ultrafine petcoke serves as a carbon raiser and foaming agent. Its precise micronization improves reaction rates and uniformity in processes like steel manufacturing and aluminum smelting. Fine carbon powders from petroleum coke enhance the efficiency and control in furnace operations.

The chemical industry also benefits from the micronization of petroleum coke. Ultrafine powders are used as fillers in various formulations, contributing to improved mechanical properties and thermal stability in specialty carbon products. Applications include rubber additives, paints, and advanced composite materials where particle size consistency is critical.

These uses highlight why technologies like fluidized bed jet milling are essential for producing ultrafine petroleum coke tailored to these diverse industrial needs. For similar industrial milling solutions, see our detailed Bangladesh Mini Quartz Jet Mill production line for insights on efficient superfine powder production.

Troubleshooting & Optimization for Ultrafine Petroleum Coke Grinding

When grinding petroleum coke ultrafine, a few common issues can impact performance and costs. Nozzle wear is frequent in air jet mills due to the high-speed particle collisions, which gradually reduce grinding efficiency and affect particle size distribution. To combat this, using ceramic wear protection linings and regularly inspecting the nozzles helps maintain optimal operation.

Another challenge is filter clogging. The fine petroleum coke powder can quickly block dust collectors if the filtration system isn’t designed for superfine powders. Regular maintenance and high-quality filter media are essential for uninterrupted airflow and stable grinding.

Energy consumption is a major factor in grinding ultrafine petroleum coke. Optimizing parameters like classifier wheel speed, air pressure, and feed rate improves grinding efficiency while lowering costs. Employing pneumatic grinding technology with precise control through PLC systems can balance throughput and energy use effectively.

Key optimization strategies include:

- Implementing wear-resistant materials to reduce maintenance downtime

- Scheduling routine filter cleaning or replacement

- Monitoring operating parameters via automation for consistent particle size (D97 28 μm target)

- Adjusting air and feed inputs dynamically to prevent energy waste

For industries requiring carbon powder micronization from petroleum coke, efficient troubleshooting and energy management maximize output quality and reduce operational expenses. For a deeper dive into grinding technology and challenges, checking out resources on the advantages and disadvantages of ball mills provides useful contrast to air jet milling. For example, learn more about the practical limits of traditional milling in this detailed ball mill advantages and disadvantages overview.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen