Talc is unique among non-metallic minerals. It is the softest mineral on earth with a Mohs hardness of 1, but its true industrial value lies in its platy (lamellar) structure and natural hydrophobicity. When we approach talcum powder ultrafine grinding, we aren’t just crushing rock; we are carefully engineering a functional additive that needs to perform in high-end applications like plastics, coatings, and cosmetics.

Unlocking Performance Through Size Reduction

Why does the industry demand finer powders? It comes down to surface area and interaction. Achieving an ultrafine particle size is critical for:

- Dispersibility: Finer particles integrate more smoothly into polymer matrices (like PP or ABS), preventing weak spots in the final material.

- Whiteness Retention: Proper grinding enhances the brightness of the powder, which is non-negotiable for the paper and cosmetic industries.

- Reinforcing Effects: In plastics, the goal is to increase stiffness and heat resistance. This relies heavily on the particle’s aspect ratio.

The Risks of Poor Processing

Grinding talc is a delicate balance. If the process is too aggressive or lacks precision, you run into two major problems that kill profitability:

- Structure Damage: If you destroy the platy structure during milling, you lose the reinforcing capability. The talc becomes a cheap filler rather than a performance enhancer.

- Agglomeration: As particles get smaller, surface energy increases, causing them to clump together. Without the right technology, you end up with inconsistent batches that fail quality control.

The Talcum Powder Ultrafine Grinding Process: Step-by-Step Overview

At EPIC POWDER, we approach the talcum powder production line as a fully integrated system rather than just a standalone machine. The journey from raw ore to high-grade powder requires strict control over every stage to ensure the final product meets the demanding specifications of modern industries.

From Raw Ore to Coarse Powder

The process begins with raw ore selection and pre-crushing. Since dry milling relies on friction and impact, the feed material typically requires a water content below 4% to prevent clogging and ensure efficiency. We use standard crushers to break down large talc rocks into a manageable feed size before they are transported via bucket elevators to the main milling unit. This transition from coarse crushing to ultrafine talc grinding is critical for maintaining a steady feed rate.

Precision Milling and Classification

Once inside the mill—whether it is a jet mill or an air classifying mill—the material undergoes intense reduction. The key to high-quality output lies in our precise classification techniques.

- Grinding: The material is pulverized to the desired fineness.

- Classifying: An integrated air classifier spins at high speeds to separate particles based on weight and size.

- Recycling: Particles that don’t meet the target D97 talc particle size are automatically rejected and sent back to the grinding zone for further processing.

This closed-loop system ensures that we achieve a consistent talc mesh fineness, capable of reaching 2500 mesh (5μm) or finer without over-grinding the material.

Collection and Surface Modification

After passing the classifier, the fine powder is collected via cyclone separators and pulse dust collectors, ensuring a dust-free environment. For applications in pigments, dyes, and printing or plastics, we often integrate talc powder surface modification directly into the line. Using equipment like pin mills or three-roller coating machines, we modify the particle surface to improve dispersibility and compatibility with polymer matrices.

Typical Process Flow:

- Crushing: Raw ore reduction.

- Feeding: Elevator transports material to the silo.

- Grinding: Main mill pulverizes the talc.

- Classifying: Separation of fine and coarse particles.

- Collecting: Finished product is gathered; air is filtered.

- Packing: Automated bagging for shipment.

Key Equipment Technologies for Ultrafine Talcum Powder Grinding

Selecting the right machinery is the most critical step in ultrafine talc grinding. At EPIC, we don’t believe in a “one-size-fits-all” approach. We configure the production line based on your specific requirements for fineness, purity, and capacity. Here is the core technology we use to deliver consistent results:

- Fluidized Bed Jet Mills: When purity is the top priority, the talc jet mill is the industry standard. These systems rely on high-speed airflow rather than mechanical impact, meaning there is minimal wear and zero metallic contamination. This is essential for producing high-whiteness, cosmetic-grade talc where quality cannot be compromised.

- Air Classifier Mills (ACM): For a balance of efficiency and operational cost, an air classifier mill for talc is highly effective. These mechanical impact mills utilize built-in turbo classifiers to precisely control particle size, typically covering the 800–3000 mesh range. They are versatile workhorses for industrial applications.

- Ball Mill and Classifying Lines: When you need high throughput for large-scale industrial fillers, we implement ball mill systems integrated with air classifiers. These lines are engineered for continuous, heavy-duty operation. Our experience with ball mill classification production sites proves that this setup delivers the most stable output for mass production.

- Low-Temperature Operation: Preserving the natural properties of talc is vital. Excessive heat during milling can destroy the talc’s lamellar structure. Our equipment is designed with optimized airflow to maintain low internal temperatures, ensuring the powder retains its reinforcing capabilities for plastics and coatings.

Critical Technical Requirements in Talcum Powder Ultrafine Grinding

Achieving premium quality in talcum powder ultrafine grinding requires strict adherence to technical benchmarks. We don’t just reduce size; we engineer the particle to fit specific industrial applications. Whether for cosmetics or polymer fillers, the process must meet rigorous standards for consistency and purity.

Precision Particle Size Control

The most critical factor is achieving a narrow particle size distribution (PSD). Uniform particles ensure better dispersion in paints and plastics. We focus on precise D97 and D99 control, ensuring that 97% or 99% of the powder is finer than the target micron size (e.g., 10μm or 5μm). This “top cut” precision prevents oversized particles from ruining the surface finish of end products. Our advanced Air Classifier Mill MJW-W is specifically designed to maintain this consistency while handling high throughputs.

Purity and Structure Preservation

- Contamination Control: To maintain talc’s natural whiteness and electrical insulation properties, we must prevent iron contamination. We utilize ceramic or polyurethane linings in the grinding chamber and pipe systems to ensure high-purity talc grinding.

- Lamellar Structure: Talc is valued for its platy shape. Aggressive milling can destroy this structure. Our process is tuned to delaminate rather than shatter, preserving the platy/lamellar structure essential for effective polymer reinforcement.

Efficiency and Automation

Modern production demands energy efficiency and throughput optimization. We integrate PLC automation to monitor system pressure, temperature, and feed rates in real-time. This ensures a dust-free, continuous operation that reduces labor costs and guarantees batch-to-batch stability.

Key Technical Benchmarks for Talc Processing

| Technical Requirement | Target Benefit |

|---|---|

| Narrow PSD | Improved flowability and dispersion in matrix |

| D97/D99 Control | Elimination of oversized particles for smooth finishes |

| Ceramic/PU Linings | High whiteness and zero metal contamination |

| Low-Temp Grinding | Prevents material degradation and agglomeration |

| PLC Integration | Stable, automated production with lower energy use |

EPIC POWDR Solutions for Talcum Powder Ultrafine Grinding

At EPIC POWDR, we engineer specialized processing lines tailored specifically to the unique physical properties of talc. Our solutions for ultrafine talc grinding rely on a robust lineup of Fluidized Bed Jet Mills and Air Classifying Mills (ACM), designed to deliver high purity and consistent particle morphology. Whether you require a standalone talc jet mill for premium cosmetic grades or a high-capacity air classifier mill for talc industrial fillers, we configure the system to match your exact specifications.

To protect the whiteness and purity of your material, we utilize ceramic lined jet mill designs. This ensures zero metallic contamination during the milling process, which is critical for high-end applications. Just as our jet mill technology enables ultrafine hard carbon production for the battery industry, we apply that same level of precision engineering to optimize your talc processing.

Key Capabilities of Our Systems:

- Customizable Fineness: We achieve precise particle sizes with the ability to grind down to a D97 talc particle size of 2μm.

- High Classifying Accuracy: Our integrated classifiers ensure a narrow particle size distribution (PSD), strictly controlling the top cut to prevent coarse particles.

- Turnkey Support: We provide complete talcum powder production lines, offering everything from raw material testing and pilot trials to full industrial installation.

- Scalability: Our designs allow you to scale seamlessly from small-batch pilot production to continuous, large-scale industrial operations.

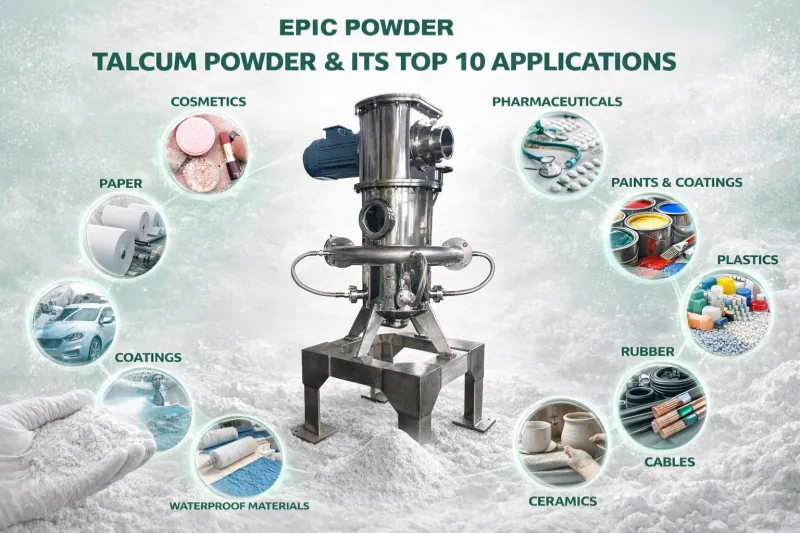

Applications of Ultrafine Talcum Powder by Fineness Range

The value of talc increases significantly as the particle size decreases. In our experience with global processing projects, precise ultrafine talc grinding allows manufacturers to tailor the powder for specific high-value uses. Different industries demand strict adherence to talc mesh fineness to ensure the end product performs as intended.

You can explore our diverse industrial material applications to see how different fineness levels impact performance across various sectors.

Breakdown by Mesh Size

- 800–1250 Mesh (General Fillers): This range is the standard for the paper industry, architectural paints, and mid-range plastics. It provides cost-effective filling properties, improving stiffness and acting as a pitch control agent without requiring extreme micronization.

- 1250–2500 Mesh (High-Performance): This is where precise D97 talc particle size control becomes critical. We see high demand for this fineness in engineering plastics (like automotive bumpers) and industrial coatings. The finer particles offer better impact resistance and smoother surface finishes.

- 2500–5000 Mesh (Premium Grade): This represents the top tier of the micronized talcum powder process. It is essential for premium cosmetics, pharmaceuticals, and advanced composites where a silky texture and sub-micron reinforcement are non-negotiable.

Real-World Benefits

Achieving these specific ranges isn’t just about hitting a number; it is about performance. Proper grinding enhances the mechanical properties of the final product, such as tensile strength and puncture resistance in polymers. Furthermore, high-quality milling preserves the whiteness of the talc, adding value to coatings and cosmetic applications while reducing the need for expensive pigments.

Case Studies: Success in Talcum Powder Ultrafine Grinding

At EPIC Powder, we measure success by the performance of the final product. Our global projects demonstrate how our talcum powder ultrafine grinding systems deliver consistent quality for high-end markets, solving real-world production bottlenecks in over 50 countries.

High-Performance Polymer Grade Talc

One of our standout projects involved a complete production line for polymer-grade talc. The client required a consistent 2500 mesh fineness to ensure the filler enhanced rather than compromised the plastic’s structural integrity. By deploying our specialized Air Classifier Mill MJW-L, we achieved a continuous output of 400 kg/h.

The results went beyond just meeting the D97 particle size requirement. Because our system integrates grinding with precise classification and surface modification, the client reported significant improvements in the end product:

- Tensile Strength: Increased by 36.7%.

- Puncture Resistance: Improved by 40.5%.

- Stability: Uniform particle distribution prevented agglomeration in the polymer matrix.

Cosmetic Grade Purity and Whiteness

For clients targeting the cosmetics industry, purity is non-negotiable. Our fluidized bed jet mill talc solutions are designed to maintain high whiteness by eliminating metal contamination during the milling process. We successfully engineered a solution that preserves the delicate lamellar structure of talc while hitting strict sub-micron targets. This approach ensures the silky feel required for premium makeup products while maximizing energy efficiency compared to traditional milling methods.

Key Project Metrics:

- Fineness: Consistent production capability below 5μm (2500 mesh).

- Capacity: Proven stable output of 400 kg/h for high-value ultrafine grades.

- Quality: Superior retention of whiteness and plate structure.

How to Select the Right Ultrafine Grinding Equipment

Selecting the optimal talcum powder ultrafine grinding system requires balancing technical specifications with economic realities. We guide our partners through a detailed evaluation to ensure the production line meets specific market demands, from heavy-duty industrial fillers to delicate cosmetic grades.

Assessing Fineness and Capacity Needs

The target particle size is the primary driver for equipment selection.

- High-End Fineness (D97 < 5μm): For applications requiring ultra-high precision, such as premium paint extenders or cosmetics, fluidized bed jet mills are the standard choice. They provide the necessary energy to break particles down to sub-micron levels without strictly relying on mechanical impact.

- High Throughput (D97 10–45μm): If your focus is on volume for paper or general plastics, an air classifier mill or a ball mill with a classifier system is often more energy-efficient. These setups deliver high capacity while maintaining a consistent talc mesh fineness.

Evaluating Purity and Budget

Purity requirements directly influence the material of construction and the total project cost.

- Contamination Control: For industries sensitive to whiteness and purity, such as pharmaceuticals and high-grade plastics, we equip machines with ceramic or polyurethane linings. This prevents iron contamination that can degrade the talc’s natural whiteness.

- Budget vs. Performance: While standard carbon steel mills are lower in upfront cost, they are unsuitable for high-value white minerals. Investing in wear-resistant linings protects the talc lamellar structure and ensures a higher market value for the final powder.

The Role of Surface Modification and Testing

For many modern applications, grinding is only half the battle. If your end product is used as a reinforcing filler in plastics or rubber, integrating a pin mill for surface modification is essential to improve compatibility with the polymer matrix. Finally, we strongly advise conducting 1:1 industrial experiments with your specific raw ore. Testing in our facility validates the talc grinding equipment comparison data, ensuring the configured solution delivers the exact PSD and throughput promised before full-scale implementation.

Frequently Asked Questions About Talc Grinding

What is the best mill for ultrafine talc powder?

The “best” mill depends entirely on your target fineness and application. For high-end applications requiring extreme fineness (D97 < 10μm) and high purity, we recommend a Fluidized Bed Jet Mill. This equipment uses high-velocity airflow to grind particles, ensuring no heat buildup and minimal contamination.

For mass production of filler-grade talc (325–1250 mesh), an Air Classifying Mill (ACM) or a Ball Mill with Air Classifier system is more cost-effective. These systems offer higher throughput while maintaining consistent particle size distribution.

How do you preserve the lamellar structure of talc during grinding?

Preserving the platy (lamellar) structure is critical for talc used in reinforcing plastics. Over-grinding destroys these plates, reducing the talc’s reinforcing properties. We utilize advanced classification technologies to remove fine particles immediately once they reach the target size, preventing unnecessary impact.

Our jet milling solutions rely on particle-to-particle collisions rather than metal impact, which is gentler on the material structure. You can see similar principles of precise particle control in our projects involving fine deagglomeration and classification with a spiral jet mill, where maintaining particle integrity is paramount.

What is the difference between D97 and mesh size in talc processing?

Mesh size refers to the number of openings in a sieve per linear inch, which is useful for coarse powders but becomes inaccurate for ultrafine powders. D97 is a statistical value indicating that 97% of the particles are smaller than a specific diameter (measured in microns).

In ultrafine grinding, D97 is the industry standard for precision.

- 1250 Mesh: Approx. D97 = 10μm

- 2500 Mesh: Approx. D97 = 5μm

- 5000 Mesh: Approx. D97 = 2.5μm

How does EPIC POWDER handle contamination control for cosmetic grades?

For cosmetic and pharmaceutical grades, purity is non-negotiable. We eliminate iron contamination by equipping our mills with ceramic linings (such as alumina or zirconia) or polyurethane coatings. This ensures the whiteness and chemical purity of the talc remain compromised during the high-energy grinding process. Additionally, our systems operate under negative pressure to ensure a dust-free, clean environment.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen