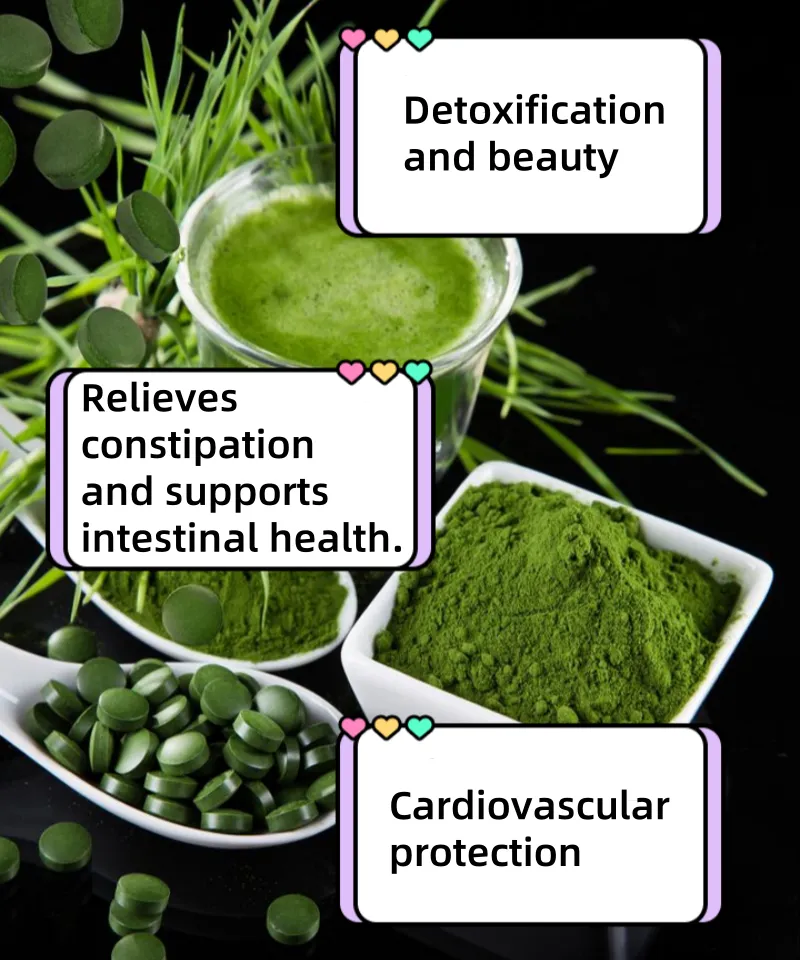

Have you noticed that in recent years, some people around you are often seen holding a cup of green, seemingly ominous liquid, drinking it down with an indescribable expression? Are you curious why they drink it despite the apparent discomfort? This trendy beverage sweeping across China is none other than “Aojiru” (green juice) from Japan. Aojiru is an instant beverage made by grinding young barley leaf into ultrafine powder. Simply mix the powder with water, and you can easily absorb the rich nutrients from barley leaves. It’s particularly suitable for people in areas with limited access to fresh, affordable vegetables due to high population density, helping them supplement essential plant-based nutrients.

The popularity of Aojiru stems from its convenience and the near-complete absorption of nutrients from its raw materials, thanks to its production process—ultrafine grinding technology. Let’s dive into how this technology transforms ordinary green leafy vegetables into a bestselling product and its applications in the food industry.

The Principle of Ultrafine Grinding Technology

Ultrafine grinding technology uses specialized equipment to crush materials through milling, impact, and shearing processes. It reduces particles larger than 3mm to ultrafine sizes of 10–25μm. This creates unique surface effects, quantum effects, and macroscopic quantum tunneling effects not found in larger particles, resulting in superior physical, chemical, and surface properties compared to macro-sized particles.

Advantages of Ultrafine Grinding Technology:

- Preserves bioactive components without generating localized high temperatures, with fast grinding speeds.

- Increases the specific surface area, adsorption, and solubility of powders, saving raw materials and improving utilization rates.

- Operates in a fully enclosed environment, preventing dust contamination and ensuring a sterile, hygienic production process.

- Produces extremely fine particles, allowing nutrients to be released quickly and absorbed easily by the small intestine, enhancing nutrient delivery.

Common Equipment for Ultrafine Grinding

Airflow Ultrafine Grinding Equipment

This method uses high-pressure gas jets to create intense impact, collision, and friction to achieve ultrafine grinding. Compared to mechanical grinding, airflow grinding produces finer, more uniform particles with a narrower size distribution. The cooling effect of gas expansion at the nozzle prevents heat buildup, making it ideal for heat-sensitive or low-melting-point materials. However, it consumes significantly more energy than other methods, and particle size increases with higher output.

High-Frequency Vibration Ultrafine Grinding Equipment

This equipment uses spherical or rod-shaped grinding media vibrating at high frequencies to apply impact, friction, and shearing forces. Supported by springs, the grinder vibrates via an eccentric shaft, typically in a cylindrical or trough-shaped structure. Vibration grinding is 10–20 times more efficient than conventional grinding, with significantly lower energy consumption than traditional ball mills.

Rotary Ball (Rod) Mill Ultrafine Grinding Equipment

This includes ball mills and rod mills, traditionally used for fine grinding but less efficient for particles below 20μm due to high energy consumption and long processing times. Stirred ball mills, however, are highly efficient, using a stirrer to drive grinding media, crushing materials through friction and minimal impact.

Impact Ultrafine Grinding Equipment

This equipment uses a high-speed rotating rotor (horizontal or vertical axis) to apply strong impact, collision, and shearing forces. It’s simple, high-capacity, stable, and energy-efficient, ideal for medium-hardness materials. For example, China’s MLC-40 high-speed impact grinder achieves excellent results, reducing 3–5mm particles to 10–40μm.

Applications of Ultrafine Grinding Technology in the Food Industry

Ultrafine grinding produces ultrafine powders with unique physicochemical properties, such as enhanced solubility, dispersibility, adsorption, and chemical reactivity. It’s widely used in food, chemicals, pharmaceuticals, cosmetics, and coatings. Below are its applications in the food industry:

Fiber-Rich Foods

Cellulose, dubbed the “seventh nutrient” by modern nutritionists, acts as a food additive or bioactive substance, helping prevent obesity and improve health through dietary fiber. Materials like wheat bran, oat husk, corn husk, soybean skin, rice bran, beet pulp, and sugarcane residue are rich in vitamins and trace elements. However, traditional processing results in large fiber particles, leading to poor texture and low consumer acceptance. Ultrafine grinding improves texture and adsorption, making these materials ideal as nutrient-rich food additives. Similarly, fruit peels and seeds can be processed into edible powders. Processing vegetables into ultra-fine powders, such as Young Barley Leaf Powder, preserves all of their vitamins. It also increases water solubility and improves the taste of the fiber due to the micronization.

Calcium-Supplemented Foods

Inedible animal and plant materials like bones, eggshells, and shrimp shells are rich in proteins, lipids, phospholipids, and chondroitin, which support brain development in children and promote skin health and anti-aging. Traditionally, boiled bones lose much of their nutritional value. Ultrafine bone powder, however, retains over 95% of nutrients, offering organic calcium that’s more bioavailable than inorganic calcium. As a byproduct of meat processing, bones are inexpensive, and processing them into calcium-rich products significantly increases their value, earning them the title of “21st-century functional food.”

Beverage Processing

Brewing tea with hot water doesn’t fully extract nutrients like vitamin A, carotenoids, and minerals, which remain in the tea leaves. Ultrafine tea powder (particle size <5μm) allows for better nutrient absorption, forming an emulsified liquid without sediment when mixed with water. Ultrafine tea powder, such as matcha, is also used as a food additive, imparting a unique tea flavor and color to desserts. Plant-based protein beverages, made from protein-rich seeds or nuts, are ground to 5–8μm and homogenized to 1–2μm, preventing protein sedimentation and fat flotation for a stable product.

Spices and Seasonings

Ultrafine grinding enhances the quality of spices and seasonings (e.g., fermented bean products). The high porosity of ultrafine powders creates cavities that retain aromas, resulting in longer-lasting, more intense flavors. The fine particle size is imperceptible to the naked eye, and the flavor intensity is several times stronger than traditionally processed seasonings.

Chocolate Processing

For chocolate to have a smooth, delicate texture, ingredient particle sizes must be below 25μm; above 40μm, the texture becomes noticeably coarse. Ultrafine grinding ensures cocoa, sugar, and milk solids reach 20–30μm, delivering a premium mouthfeel. Countries like Switzerland and Japan use ultrafine grinding in chocolate production, contributing to their globally renowned chocolate quality.

Epic Powder

Ultrafine grinding technology, as exemplified by Epic Powder’s advanced powder processing equipment, is versatile, straightforward to implement, and significantly enhances product value, delivering substantial economic benefits. This transformative technology, particularly when applied to producing young barley leaf powder, revolutionizes traditional food processing, enables the development of innovative products, and advances the creation of functional foods with superior nutritional profiles.