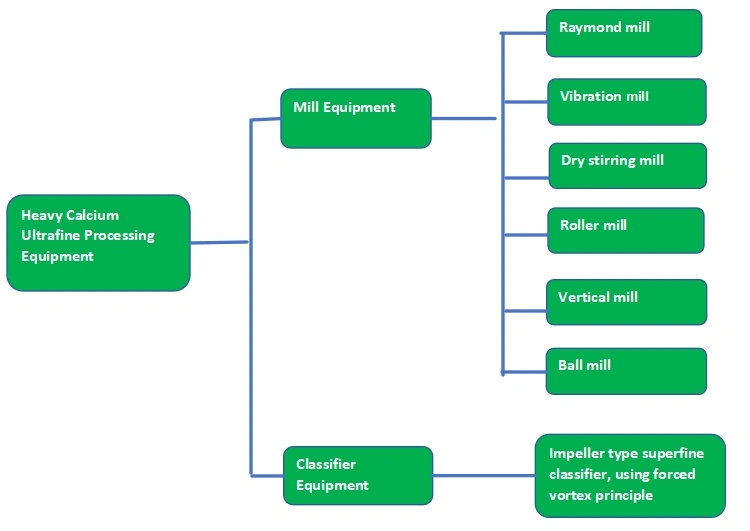

There are many types of heavy calcium ultrafine processing equipment. They work with ultrafine classifiers to form ultrafine processing systems. These systems can generally achieve ultrafine production results. Currently, the mainstream demand in the calcium market is 600-1500 mesh heavy calcium products. The added value of heavy calcium products is low (compared to talc, barytes, kaolin, etc.). Scale is one of the main factors affecting efficiency. Today, we will discuss the ultrafine processing equipment used in the dry process of heavy calcium.

Heavy Calcium Ultrafine Processing Equipment

Comparison of Various Ultrafine Processing Equipment

| Device Type | Product fineness (mesh) | Optimal fineness (mesh) | Advantages | Disadvantages |

| Raymond mill | 100-1250 | <400 | Great advantages in producing products below 400 mesh | Low content of micro powder Low production capacity of products above 800 mesh |

| Vibration mill | 1250-2500 | >1250 | High grinding efficiency High content of fine powder | Large aspect ratio Serious over-grinding |

| Dry stirring mill | 1252-6000 | >2500 | High grinding efficiency | |

| Roller mill | 400-1500 | <1500 | Electricity saving Low investment | Low output per machine Poor product stability |

| Vertical mill | 200-1500 | <400 | High crushing efficiency | |

| Ball mill classifier | 600-6500 | 800-2500 | Large production scale of single machine |

As seen above, although equipment like Raymond mills are commonly used by heavy calcium enterprises, most of these devices struggle to achieve large-scale production of ultrafine heavy calcium.

Currently, in Europe, the United States, and other countries and regions where they provide technology and equipment, the processing technology and equipment are mainly ball mills paired with large classifiers.

Practice has shown that for large-scale dry production of ultrafine heavy calcium products above 600 mesh, the technologies and equipment suitable for the development of this industry mainly fall into two categories: high-fineness ball mills paired with ultrafine classifiers, and ultrafine vertical mills paired with ultrafine classifiers. A comparison of the processing systems of vertical mills and ball mills is shown in the table below.

| Parameter | Ball mill+ classifier | Vertical mill+ classifier |

| Single machine production scale | Bigger | Big |

| <400 mesh | Not suitable | Very suitable |

| 400-600 mesh | Relatively suitable | Very suitable |

| 400-600 mesh | High power consumption, but the product surface area is also high | Low power consumption |

| 600-1000 mesh | Very suitable | Very suitable |

| 600-1000 mesh | The power consumption is high, but the product has a high specific surface area | Low power consumption |

| >1000 mesh | Very suitable | Secondary classification required |

| >1000 mesh | Stable product quality Higher specific surface area | Powders after secondary classification Product quality fluctuates |

| Power consumption <1250mesh | High | Low |

| Power consumption >1250mesh | Same as <1250 mesh products | Slightly higher |

| Product Application | More suitable for paper and coatings industries | More suitable for plastics industries |

Conclusion

The demand for ultrafine heavy calcium powder below 2μm is rapidly increasing, and the research on large sub-micron classifiers is currently a key task. The combined use of multiple large classifiers is an effective method for diversifying products simultaneously. The use of ball mills and large classifiers has made large-scale single-machine production of heavy calcium possible. The ball mill has the largest single-machine capacity, and its performance is more prominent when producing products above 1250 mesh. On the other hand, the ultrafine vertical mill shows significant energy-saving effects when producing heavy calcium products in the 400-1000 mesh range.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !