Graphite is one of the most classical members of the carbon family. It has long dominated lithium-ion battery anode materials. This is due to its excellent thermal conductivity and electrical conductivity. Graphite also offers high-temperature resistance and lubricating properties. It has been listed as a critical raw material by the EU and the United States. Australia and other regions have made similar strategic classifications. From natural flake graphite to high-purity graphite, applications continue to expand. Spherical graphite and specialty graphite further broaden its industrial value. The graphite family shows strong versatility across many industries. Typical fields include metallurgy, electronics, chemicals, and aerospace. Advanced processing, especially graphite ultrafine grinding, enables these high-performance applications.

However, with the rapid growth of new energy vehicles and energy storage systems, the theoretical capacity of conventional graphite anodes (372 mAh/g) is approaching its limit, making it difficult to meet the demand for higher energy density batteries. Silicon–carbon anode materials have therefore emerged as a key breakthrough technology to overcome this bottleneck.

From naturally occurring flake graphite and microcrystalline graphite to artificial graphite, high-purity graphite, specialty graphite, battery-grade spherical graphite, and graphene, the graphite material system is continuously evolving toward higher purity, controllable particle size, lower impurity levels, and greater consistency. This evolution is inseparable from advances in graphite ultrafine grinding, classification, and surface modification technologies.

Natural Graphite: A Fundamental Carbon Source for Silicon–Carbon Anodes

Natural graphite is a graphite mineral formed in nature, and its crystallization characteristics directly determine its processing routes and application potential. Industrially, natural graphite is typically classified into crystalline graphite and microcrystalline graphite.

Crystalline Graphite (Flake and Dense Graphite)

Flake graphite occurs in plate-like or leaf-like crystals, typically larger than 1 μm. It exhibits excellent floatability, lubricity, and plasticity, making it the preferred raw material for producing spherical graphite and silicon–carbon composite anodes.

In anode material preparation, flake graphite usually undergoes mechanical shaping, ultrafine grinding, classification, and purification to achieve suitable particle size distribution and specific surface area.

Dense crystalline (block) graphite generally contains 60%–65% carbon, with lower plasticity and lubricity. Its application in lithium battery anodes is limited, and it is mainly used in traditional refractory and metallurgical fields.

Microcrystalline Graphite

Microcrystalline graphite consists of extremely fine crystallites and has a dull, earthy appearance. It typically exhibits high natural grade, with some deposits exceeding 90% carbon. With advances in high-temperature purification and jet milling technologies, microcrystalline graphite is increasingly used in conductive additives and carbon-coating systems for silicon–carbon anodes.

Artificial and High-Purity Graphite: Performance Stabilizers for Silicon–Carbon Anodes

Artificial graphite is produced from petroleum coke and pitch coke as aggregates, shaped, baked, and graphitized at high temperatures. With its highly controllable structure and high purity, it is an essential material for high-end power battery anodes.

High-Purity Graphite

High-purity graphite typically refers to graphite with a carbon content ≥99.9% (or ≥99.99% in some applications). Its key advantages include:

- High electrical conductivity and low internal resistance

- Excellent chemical stability

- Extremely low impurity and metal ion content

In silicon–carbon anode systems, high-purity graphite is often used as a conductive framework or carbon coating source. Through precise grinding and classification, its particle size and morphology can be finely controlled, helping to mitigate silicon’s severe volume expansion.

Spherical Graphite: The Structural Backbone of Silicon–Carbon Anodes

Spherical graphite is produced from high-carbon flake graphite through mechanical shaping, grinding, classification, and surface modification, forming ellipsoidal particles. It is the mainstream morphology for lithium-ion battery anodes.

Silicon has a theoretical capacity of up to 4200 mAh/g—more than ten times that of graphite—but suffers from up to 300% volume expansion during cycling, leading to particle pulverization, repeated SEI rupture, and rapid capacity decay. Silicon–carbon anodes address this challenge by compositing nano-silicon (or SiOx) with carbon materials, particularly graphite.

Mainstream preparation routes for silicon–carbon anodes include:

- Ball milling, where nano-silicon is physically mixed or coated onto spherical or artificial graphite;

- Chemical vapor deposition (CVD), where nano-silicon is deposited within porous carbon matrices (often graphite or hard carbon), currently the dominant industrial route.

In these processes, spherical graphite plays a pivotal role. Its rounded shape, good flowability, and high tap density make it the preferred composite matrix. After surface modification, spherical graphite can form stable core–shell or porous composite structures with nano-silicon, significantly improving processability and cycling stability.

High-purity graphite and expanded graphite are also widely used to construct conductive networks or provide volume buffering, while graphene-enhanced silicon–carbon anodes have become a major research focus in recent years.

Graphene and Expanded Graphite: Functional Enhancers in Silicon–Carbon Systems

Graphene, composed of single or few layers of carbon atoms, offers exceptional electrical conductivity and mechanical strength. In silicon–carbon anodes, graphene is used to build conductive networks, improving rate capability and cycle life. Its preparation relies heavily on ultrafine grinding and exfoliation of high-purity graphite.

Expanded graphite and flexible graphite serve as carbon-coating or buffering materials. Through high-temperature expansion and mechanical compression, they form porous structures that effectively accommodate silicon’s volume changes.

Specialty and Nuclear-Grade Graphite: Foundations for Advanced Equipment and Anode Manufacturing

Specialty graphite and nuclear-grade graphite feature extremely high purity, density, and structural uniformity. They are widely used in:

- Carbon-coating reactors for silicon materials

- Linings for high-temperature heat-treatment furnaces

- Graphitization equipment for silicon–carbon anode production

Their manufacture relies heavily on isostatic pressing, ultrafine grinding, and high-temperature purification, with stringent control over particle size and trace impurities.

Grinding Equipment: The “Behind-the-Scenes Hero” of Silicon–Carbon Anode Production

The performance of silicon–carbon anodes depends strongly on particle uniformity and nanoscale structural control, making grinding equipment a core component of the process:

- High-energy ball mills: Used for nano-sizing silicon and uniformly compositing it with graphite, enabling silicon dispersion or coating through intense impact and shear.

- Nano grinders / bead mills: Widely applied in wet processes to reduce silicon particles below 50 nm while minimizing agglomeration.

- Grinding combined with spray drying: Many advanced processes first prepare uniform slurries via ball or bead milling, followed by spray drying and carbonization to form quasi-spherical composite particles.

These grinding systems directly determine particle size distribution, specific surface area, initial coulombic efficiency, cycle life, and rate performance. With the rise of CVD-based routes, grinding equipment is increasingly used to precisely engineer porous carbon frameworks for subsequent silicon deposition.

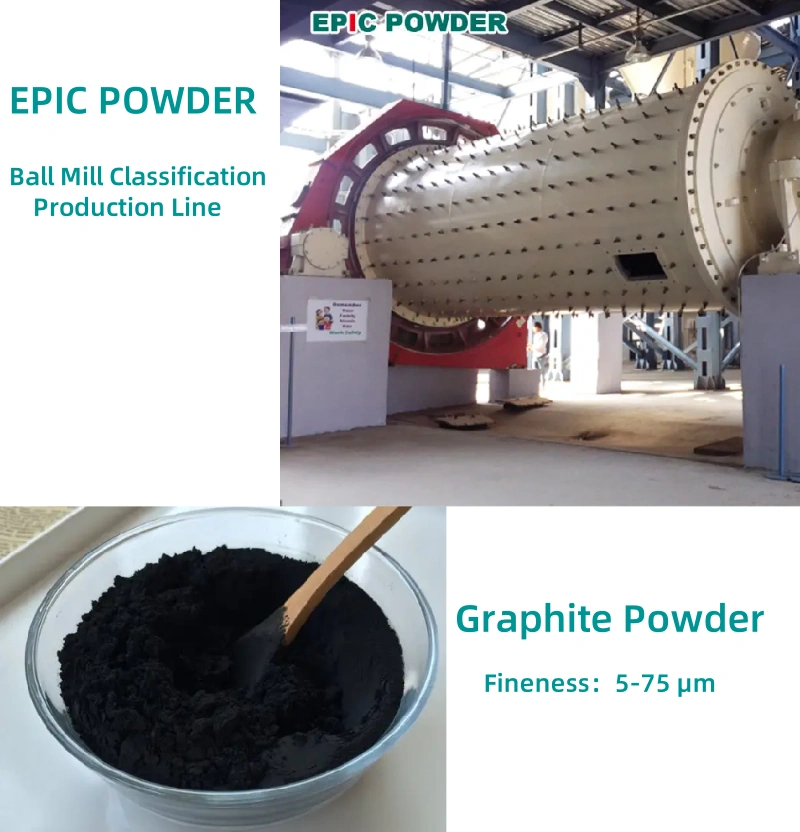

Conclusion: Epic Powder Empowering the Silicon–Carbon Future

As silicon–carbon anodes move toward large-scale commercialization, powder engineering precision becomes a decisive factor. Epic Powder, with over 20 years of experience in ultrafine grinding, air classification, and surface modification, provides customized solutions for graphite, silicon, and silicon–carbon composite materials. Through advanced ball mills, jet mills, classifier mills, and integrated grinding–classification systems, Epic Powder helps battery material producers achieve precise particle control, high purity, and consistent performance—laying a solid foundation for the next generation of high-energy-density lithium-ion batteries.

Are you ready to accelerate the silicon–carbon revolution?

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen