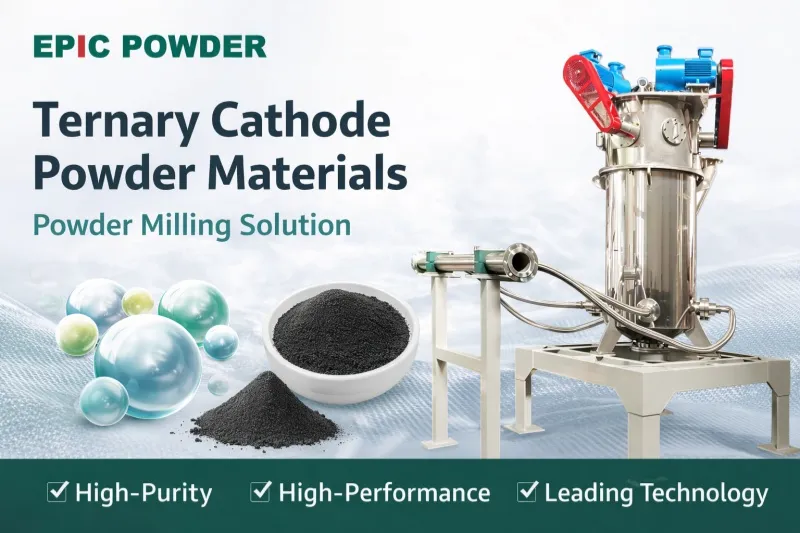

How to Achieve D50 < 1μm in NCM Ultrafine Pulverization Without Damaging Crystal Structures?

In the field of lithium-ion battery cathode materials, NCM (nickel-cobalt-manganese ternary layered oxide, LiNiₓCoᵧMnzO₂) has become one of the mainstream choices for electric vehicle power batteries due to its high energy density, good cycling stability, and relatively low cost. With the trends toward high-nickel content (Ni ≥ 80%) and single-crystal/nanocrystallization, reducing the D50 (median volume […]

What are Research Status and Challenges of Prussian Blue Cathode Materials for Sodium-Ion Batteries?

In recent years, lithium-ion batteries have been widely used in power and energy storage markets. As a result, lithium resources have become increasingly scarce. Sodium-ion batteries operate on a similar principle and show comparable performance to lithium-ion batteries. However, compared with lithium-ion batteries, sodium-ion batteries have several clear advantages: They also offer good power performance, […]

What are the 20 Intensive Processing Technologies and Systems for Bentonite?

Bentonite processing refers to the comprehensive upgrading, purification, modification, and high-value application technologies applied to bentonite, a hydrated clay rock mainly composed of montmorillonite. Bentonite possesses excellent swelling capacity, adsorption, cation exchange capacity, catalytic activity, bonding performance, suspension stability, and plasticity. It is widely known as “all-purpose clay.” Natural bentonite often contains gangue minerals such […]

How Does Ultrafine Grinding Technology Enable Talc, the “Softest Mineral,” to Cross into High-end Manufacturing Fields?

Talc, a mineral often overlooked, ranks dead last on the Mohs hardness scale, yet its “softness” delivers remarkable “hardcore” strength. As the softest known mineral, talc plays important roles not only in daily life but also shines across multiple industries. However, its true potential is often unlocked through the process of producing ultrafine grinding talc, […]

What Are the Causes of Low Activity During Slag Powder Grinding and Their Solutions?

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and a complete crystal structure are primary factors. Furthermore, a high content of acidic oxides like SiO2 and a low content of basic oxides like CaO further reduce activity. When analyzing […]

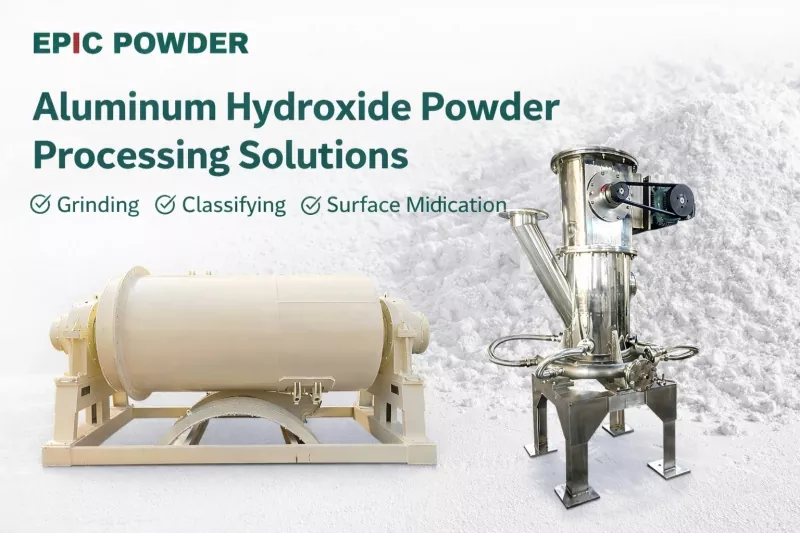

What Are the Preparation Processes of Ultrafine Aluminum Hydroxide Powder and Its Surface Modification Mechanisms?

Aluminum hydroxide (ATH) possesses multiple functions, including flame retardancy, smoke suppression, and filling. It does not produce secondary pollution and can generate synergistic flame-retardant effects with various substances. Therefore, it is widely used as a flame-retardant additive in composite materials and has become the most widely consumed environmentally friendly inorganic flame retardant. When aluminum hydroxide […]

Why is Ultrafine Grinding Becoming Essential for Modern Bentonite Applications?

Bentonite is widely acclaimed as the “Universal Clay,” with its core mineral constituent being Montmorillonite. This layered silicate, forged from volcanic ash over millions of years, spans two vastly different worlds: from $10-a-bag cat litter to high-precision chemical additives. This versatility is not merely a result of its natural chemistry, but rather a masterpiece of […]

Does Ultra-fine Pulverization of Sodium Carbonate Really Solve the Poor Rate Performance Problem of Sodium-ion Batteries?

Sodium-ion batteries (SIBs) have attracted significant attention in recent years due to abundant sodium resources, low cost, and advantages in low-temperature performance and safety. However, compared to mature lithium-ion batteries, SIBs still face a prominent shortcoming — poor rate capability. Rate capability refers to a battery’s ability to maintain capacity and enable fast charge/discharge at […]

How to Achieve Morphology Control of Powder Particles?

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and the final microstructure and performance of ceramic products. The objective of morphology control is to obtain particle shapes that are specific, uniform, and reproducible. The following sections detail the mainstream […]