What Are the Causes of Low Activity During Slag Powder Grinding and Their Solutions?

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and

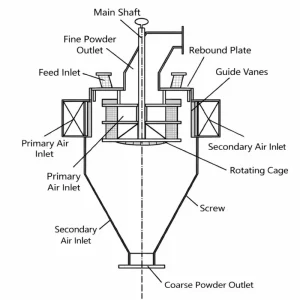

MJW-L air classifier mill is driven independently by the horizontal crushing disc and classifying wheel, and the classifying wheel is installed vertically. The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to centrifugal force and collides with the crushing ring gear. The comprehensive effect of various forces such as impact, shear, friction, and collision to make the material into powder. The ground material moves to the classification area with the airflow, and the coarse and fine materials are separated by the frequency conversion regulated classifying wheel. The fine powder products that meet the fineness requirements are brought into the cyclone and dust collector by the airflow, and the coarse materials are returned to the grinding area for re-grinding.

The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision. The material is ground, and the crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the classification wheel adjusted by the frequency conversion. The products that meet the fineness requirements enter the cyclone collector and the dust collector with the airflow for collection, and the coarse particles return to the grinding area to continue shattered.

| Model | 300 | 400 | 500 | 700 | 800 | 900 | 1000 | 1100 | 1250 | 1500 | 2000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Power(kw) | 7.5 | 22 | 30 | 45 | 55 | 75-90 | 90 | 110-132 | 160-200 | 250 | 355 |

| Rotating speed(rpm) | 7500 | 4800 | 4200 | 3000 | 2800 | 2350 | 2100 | 1920 | 1800 | 1500 | 1120 |

| Motor Power(kw) | 2.2 | 4 | 5.5 | 7.5 | 7.5-11 | 15 | 15-22 | 22-30 | 22-37 | 45-55 | 55-75 |

| Rotating speed(rpm max) | 4500 | 3250 | 3000 | 2920 | 2500 | 2200 | 2000 | 1800 | 1800 | 1500 | 1150 |

| Fineness (μm) | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 |

| Capacity (kg/h) | 2-100 | 10-1000 | 15-1500 | 20-2000 | 25-2500 | 40-4000 | 45-4500 | 60-6000 | 75-75000 | 100-1000 | 15-15000 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

1. Causes of Low Activity of Slag Powder Many factors contribute to the low activity of slag powder. A high proportion of crystalline phases and

Aluminum hydroxide (ATH) possesses multiple functions, including flame retardancy, smoke suppression, and filling. It does not produce secondary pollution and can generate synergistic flame-retardant effects

Bentonite is widely acclaimed as the “Universal Clay,” with its core mineral constituent being Montmorillonite. This layered silicate, forged from volcanic ash over millions of

Sodium-ion batteries (SIBs) have attracted significant attention in recent years due to abundant sodium resources, low cost, and advantages in low-temperature performance and safety. However,

Morphology control of powder particles is one of the core technologies in advanced material preparation. It directly determines the packing density, flowability, sintering activity, and

Centella asiatica (also known as Gotu Kola) is an important medicinal and edible plant. Its key active compounds — primarily triterpenoids (such as asiaticoside, madecassoside,

Particle classification refers to separating particles of the same material according to differences in physical properties such as particle size, shape, or density. In most

Macro Background: Humanoid Robots Enter the “Lightweight Era” As humanoid robots enter their first year of mass production, the industry is facing unprecedented technological challenges

WhatsApp us

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.