Key factors in the application of air jet mill technology and equipment selection

In recent years, the superior properties of ultrafine particles have gained increasing recognition. More and more researchers are focusing on the study of fine powder

MJL-W air classifier mill is driven independently by the crushing disc and the classifying wheel, the crushing disc is installed vertically, and the classifying wheel is installed horizontally. The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to centrifugal force and collides with the crushing ring gear. The comprehensive effect of various forces such as impact, shear, friction, and collision causes the material to be ground. The ground material moves to the classification area with the airflow, and the coarse and fine materials are separated by the frequency conversion regulated classification wheel. The fine powder products that meet the fineness requirements are brought into the cyclone and dust collector by the airflow, and the coarse materials are returned to the grinding area for re-grinding.

The material is uniformly sent into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to the centrifugal force to collide with the crushing ring gear, and is subjected to various comprehensive forces such as shearing, friction, and collision. The material is ground, and the crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the classification wheel adjusted by the frequency conversion. The products that meet the fineness requirements enter the cyclone collector and the dust collector with the airflow for collection, and the coarse particles return to the grinding area to continue shattered.

| Parameter Model | 500 | 600 | 800 | 1000 | 1250 | 1500 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding | Motor Power(kW) | 30 | 37 | 55 | 90 | 160-200 | 250 | |||||

| Rotating speed(rpm) | 4200 | 3380 | 2800 | 2100 | 1800 | 1500 | ||||||

| Classifying | Motor Power (kW) | 5.5 | 7.5 | 7.5~11 | 15~22 | 22~37 | 37~45 | |||||

| Rotating speed(rpm max) | 4650 | 4000 | 3000 | 2400 | 1900 | 1500 | ||||||

| Draft Fan | Air volume(m³/h max) | 3000 | 4000 | 5400 | 10000 | 16500 | 22500 | |||||

| Fineness (μm) | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | 5-300 | ||||||

| Capacity | Capacity(kg/h) | 15-1500 | 20-2000 | 25-2500 | 45-4500 | 75-7500 | 100-1000 | |||||

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

In recent years, the superior properties of ultrafine particles have gained increasing recognition. More and more researchers are focusing on the study of fine powder

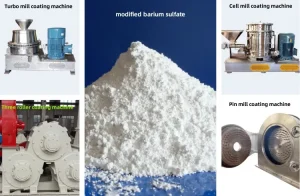

Barium sulfate has unique and excellent properties, making it widely used. It is a new functional modification material for plastics. Modified barium sulfate significantly improves

Superfine powders refers to materials with micron to nanometer particle sizes. In mineral processing, ultrafine powder means 100% particle size less than 30μm. Nanomaterials show

Quartz is a widely distributed mineral in the Earth’s crust. Its chemical composition is silicon dioxide (SiO₂). Due to its unique physical and chemical properties,

With the continuous advancement of industrialization, the amount of solid waste generated has been increasing year by year. Effectively treating this waste and reducing environmental

In the food processing industry, achieving consistent particle size, preserving product integrity, and maintaining hygiene standards are critical priorities. Among the various grinding technologies available,

In modern medicine, drug development seeks higher quality and efficacy. Particle size and distribution critically impact drug performance. Disc jet mill, as advanced grinders, are

As the food industry evolves, grinding technology becomes increasingly crucial. It affects food quality, taste, nutrition, and efficiency. Consumers demand diverse, refined, and nutritious food. This drives innovation

THE MACHINES WE CAN PROVIDE

CONTACT OUR TEAM

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

© 2000-2023 Calcium Carbonate High-Value Process Expert | EPIC powder Machinery Co., Ltd. | All rights reserved | Privacy policy

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.