Brazil possesses abundant dolomite mineral resources, whose processed products are widely used in coatings, papermaking, plastic and rubber fillers, as well as building materials.

In recent years, ultrafine grinding of dolomite has become a key processing step to improve filler performance and application value. This Brazilian customer is committed to producing high-quality industrial fillers and has strict requirements for particle size distribution consistency and low-energy equipment operation. To achieve large-scale production while reducing maintenance costs, the customer introduced the Epic Powder ball mill–classifier production line.

Key Processing Parameters

- Material: Brazilian dolomite (moderate hardness, high brittleness)

- Core Equipment: Epic Powder ball mill–classifier production line

- Product Requirement: D97 = 75 μm (approximately 200 mesh standard)

- Applications: Industrial fillers and special construction mortars

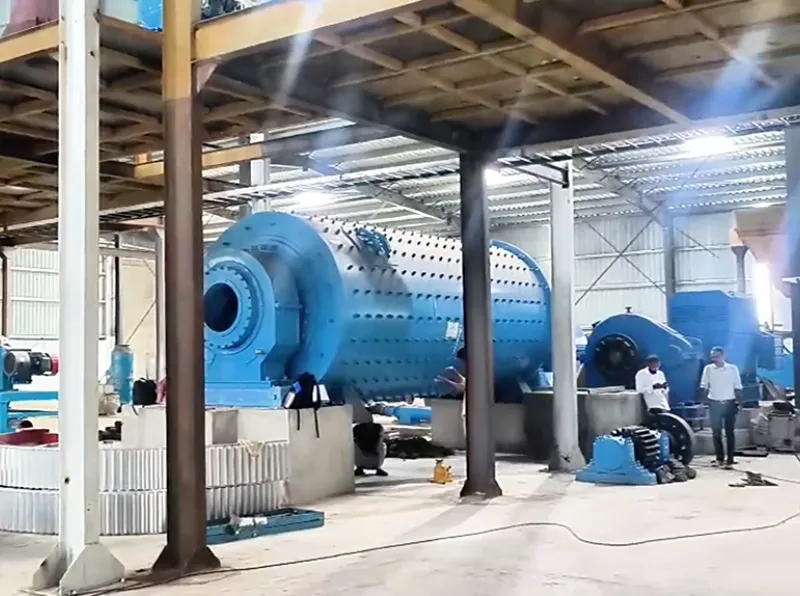

Solution: Ball Mill–Classifier Production Line System

For a fineness requirement of 75 μm, conventional crushing equipment alone cannot meet the precision demanded by Ultrafine Grinding of Dolomite, while vibration mills often lead to excessively high energy consumption. The ball mill–classifier system provided by Epic Powder maximizes efficiency through a closed-circuit process integrating grinding and precision air classification.

1. Grinding Stage: Customized Ball Mill

The ball mill is equipped with high-alumina liners and ceramic grinding media specifically designed for dolomite characteristics. This configuration effectively prevents iron contamination during processing (ensuring dolomite whiteness) and, through scientifically optimized media grading, increases the contact area between material and media, significantly improving grinding efficiency.

2. Classification Stage: High-Precision Air Classifier

This is the core step to ensure D97 = 75 μm. After grinding, the powder is carried by airflow into the classifier:

- Precise Control: By adjusting the classifier rotor speed, particles larger than 75 μm are accurately intercepted.

- Automatic Recirculation: The separated coarse particles are automatically conveyed back to the ball mill via a screw conveyor for regrinding, forming a closed loop with no material waste.

3. Collection and Dust Removal

The finished fine powder is collected by a cyclone, while the exhaust gas is filtered through a pulse bag dust collector. The emission concentration is below national environmental standards, fully meeting local environmental regulations in Brazil.

Performance Advantages Evaluation

| Indicator | Performance Description |

|---|---|

| Product Quality | Very narrow particle size distribution; D97 stably controlled at 75 μm with almost no loss of whiteness. |

| Energy Efficiency | Compared with traditional processes, overall energy consumption is reduced by approximately 20–30% through variable-frequency classifier control. |

| Wear Resistance | Key components are protected with wear-resistant ceramic tiles, greatly extending maintenance intervals. |

| Automation | The entire system is PLC-controlled with one-button start/stop, minimizing quality fluctuations caused by manual intervention. |