In South Korea, a new energy company developing porous carbon anode materials faced a major challenge — severe agglomeration and poor dispersion of the material. These issues negatively affected its specific surface area and electrical conductivity. To solve this problem, the company collaborated with EPIC Powder to successfully implement a Porous Carbon Pin Mill Dispersion Project.

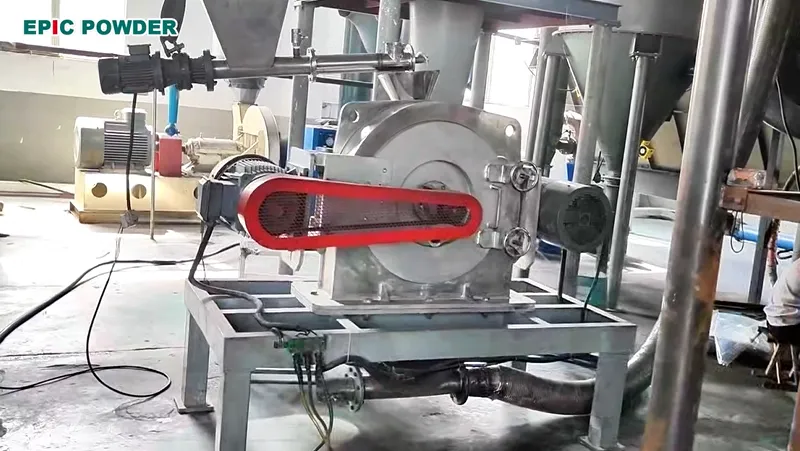

Porous carbon has the characteristics of being lightweight, prone to agglomeration, and vulnerable to high temperatures. EPIC Powder utilizes a custom-optimized pin mill system. This equipment utilizes a mechanical impact method involving high-speed relative rotation of a pin and a disc. This method fully disperses agglomerates while preventing structural damage to the carbon material caused by intense friction.

The entire system operates under an inert gas protection atmosphere, which prevents oxidation and ensures safe operation. After dispersion, the carbon powder exhibits uniform particle size distribution and significantly improved dispersion performance, with a specific surface area retention rate exceeding 97%. This provides an excellent pre-treatment foundation for subsequent coating, granulation, and electrochemical performance enhancement.

The successful commissioning of this project greatly improved the electrode consistency and cycling stability of the customer’s porous carbon material.

This case highlights EPIC Powder’s strong technical expertise in fine dispersion and de-agglomeration of carbon materials, providing efficient and reliable solutions for new energy material enterprises in South Korea and worldwide.

Material:Porous Carbon

Output : 1T/h