Customer Profile:

The client is a well-known Japanese manufacturer of rare-earth permanent magnetic materials, with extremely high standards for the performance of neodymium iron boron (NdFeB) magnets. To further enhance remanence and coercivity, the customer required sintered NdFeB coarse powder to be finely ground to a uniform micron-scale particle size through a highly controlled NdFeB Pulverization process.

Core Requirements:

- Particle Size Distribution: D97 = 4 μm with an extremely narrow distribution to improve magnetic grain orientation.

- Oxygen Content Control: NdFeB is highly prone to oxidation, so oxygen pickup during the grinding process must be strictly controlled.

- Efficiency and Stability: Japanese customers demand exceptionally high continuous operation stability and batch-to-batch consistency from the equipment.

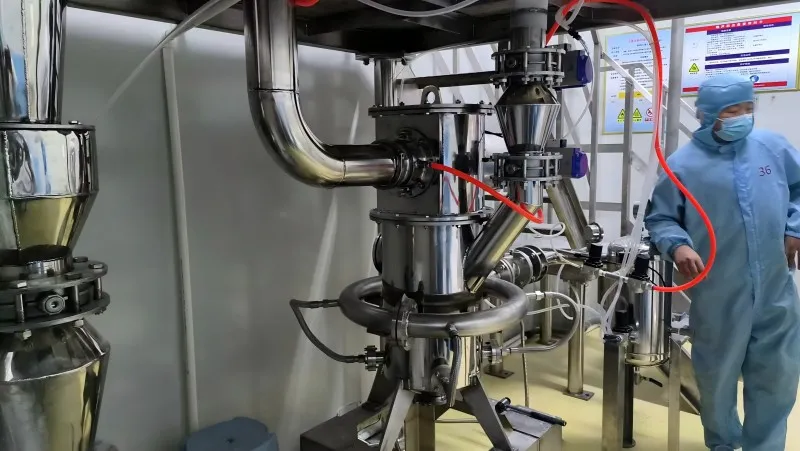

Solution: Epic Powder MQW Series Fluidized Bed Jet Mill

Based on the unique physical properties of NdFeB materials and the customer’s stringent precision requirements, Epic Powder provided a customized solution using the MQW Series Fluidized Bed Jet Mill, specifically engineered for high-precision NdFeB Pulverization applications.

1. Core Technical Advantages

- Multi-Nozzle Supersonic Jetting:

Utilizing fluidized bed principles, particles are accelerated and fractured through high-speed gas-driven self-collision. This significantly reduces contact between the material and the mill’s internal walls, minimizing metallic contamination. - Precision Classification System:

The system integrates a high-precision turbo classifier. By precisely controlling the classifier wheel speed via frequency conversion, D97 is stably maintained at 4 μm while effectively removing both oversized and excessively fine particles. - Full Inert Gas Protection (N₂ / Ar):

The entire grinding system adopts a fully enclosed closed-loop design, filled with high-purity nitrogen or argon. An online oxygen analyzer provides real-time interlocking control, strictly maintaining system oxygen levels below 50 ppm to prevent oxidation and ensure product quality.

2. Process Parameter Overview

| Parameter | Setting / Description |

|---|---|

| Processed Material | Neodymium Iron Boron (NdFeB) coarse powder |

| Final Fineness | D97 = 4.0 μm ± 0.2 μm |

| Grinding Medium | High-purity Nitrogen (N₂) |

| Feeding Method | Pneumatic sealed automatic feeding |

| Lining Material | Fully ceramic wear protection (Al₂O₃ / SiC) |