A ceramic raw material company in Nigeria specializes in producing high-grade tiles and sanitary ware. The purity and particle size distribution of its ceramic clay (kaolin) are critical to product quality. Traditional sieving methods were inefficient and inconsistent in fine powder control, affecting sintering density and surface smoothness of the final products.

Customer Requirement

The customer sought a high-efficiency classification system to achieve precise particle size control of ceramic clay, targeting D97 ≤ 10 μm while improving product consistency and yield.

EPIC Powder Solution

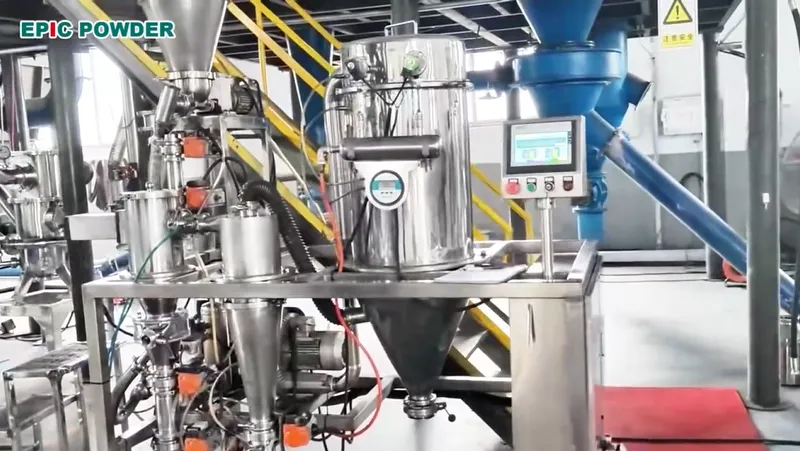

EPIC Powder provided a air classifier system specially designed for ceramic clay. The system features an adjustable rotor and high-precision classifier wheel, enabling efficient separation of fine particles. All parts in contact with the material are lined with ceramic to prevent metal contamination and ensure product purity.

Results

- Narrow particle size distribution, with D97 stabilized between 8–10 μm

- Product purity increased by 5%, with significantly fewer impurities

- Stable continuous operation and extended maintenance intervals

- Noticeably smoother surface finish of sintered ceramic products