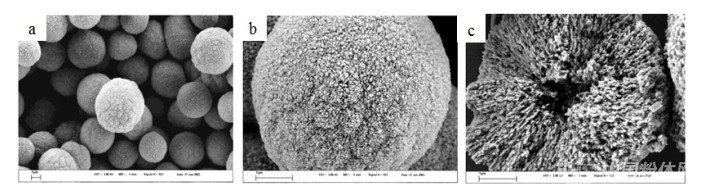

What is Porous Calcium Carbonate and Its Uses?

Porous calcium carbonate (CaCO3) particles are gaining attention for use in chromatography, biomolecule loading, and pharmaceuticals release. They are also applied in biomimetic minerals and superhydrophobic surface construction. Preparation Technology of Porous Calcium Carbonate The template method has become the main approach for preparing porous calcium carbonate.Surfactants, polymers, and natural plant components are used as […]

Properties and Applications of Precipitated Calcium Carbonate

Precipitated Calcium Carbonate (PCC), also known as light calcium carbonate, is made from calcining limestone and other raw materials. Limestone is first calcined to produce lime (mainly calcium oxide) and carbon dioxide. Water is added to the lime to form lime slurry (mainly calcium hydroxide). Carbon dioxide is then passed into the lime slurry to […]

Modified Wollastonite : High Value and High Efficiency

Wollastonite is a fibrous silicate mineral with a needle-like structure and high whiteness. It has a low coefficient of thermal expansion, excellent chemical stability, and flame-retardant properties. It also has high electrical insulation, making it suitable for various applications. However, natural wollastonite is hydrophilic. To enhance resource utilization and add value, modified wollastonite is necessary. […]

What are the Mineral Powders in Cosmetics ?

Mineral powders are increasingly used in cosmetics, such as pigment powders, white powders, filler powders, and pearl powders. Pigment powders adjust the color of cosmetics.White powders provide coverage, whitening, and UV blocking. Filler powders regulate product spreadability, adsorption, skin adhesion, texture, and active ingredient loading. Pearl powders enhance product gloss and texture. Physical Powder – […]

What Are the Main Applications of Limestone ?

Limestone, also known as “Qing Stone” or “Gray Rock,” is a mineral aggregate primarily composed of calcite. It often contains dolomite, magnesite, and other carbonate minerals. The chemical composition of pure limestone is close to the theoretical composition of CaCO3, with CaO accounting for 56.04% and CO2 for 43.97%. Limestone is a common non-metallic mineral […]

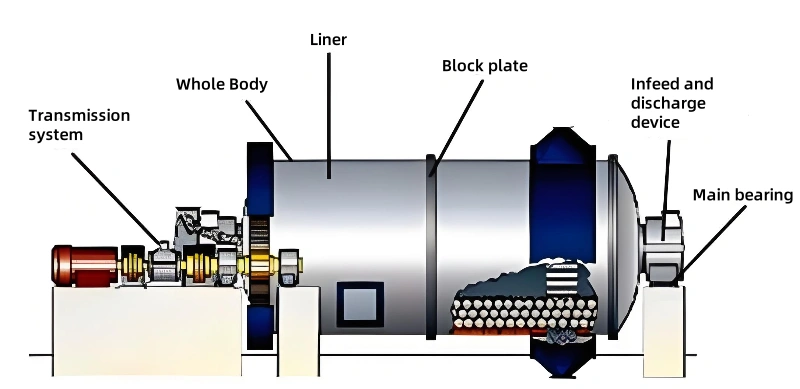

Ball Mill for Powders

Ball mill is a key equipment for crushing materials after they are broken. Ball mill for powders is one of the high-fine grinding machines widely used in industrial production. It is suitable for grinding various ores and other materials. It is widely used in mineral processing, building materials, and chemical industries. Why is it Called […]

Application and Characteristics of Heavy Calcium Carbonate in Coatings

Heavy calcium carbonate in coatings is derived from natural minerals like limestone and marble through mechanical grinding. It acts as a multifunctional filler to enhance coverage, mechanical strength, and weather resistance. Its lamellar structure reinforces film integrity. Low oil absorption and minimal VOC emissions make it ideal for eco-friendly water-based coatings. The material’s whiteness and […]

Heavy Calcium Ultrafine Processing Equipment

There are many types of heavy calcium ultrafine processing equipment. They work with ultrafine classifiers to form ultrafine processing systems. These systems can generally achieve ultrafine production results. Currently, the mainstream demand in the calcium market is 600-1500 mesh heavy calcium products. The added value of heavy calcium products is low (compared to talc, barytes, […]

What is the Preparation Technology of Barite Powder?

Barite powder is derived from the mineral barite, composed of barium sulfate (BaSO₄). It forms in low-temperature hydrothermal veins and sedimentary rocks. The chemical composition includes 65.7% BaO and 34.3% SO₃. Substitutions of Sr, Pb, and Ca can also occur in its structure. Barite powder typically appears as plate-like, granular, fibrous aggregates, and crystal clusters. […]