Rare Earth Powder Grinding: The Key Step to High-Performance Materials

Rare earth elements, often referred to as the “vitamins of industry”. It plays an essential role in a wide range of fields such as permanent magnet materials, phosphors, catalysts, hydrogen storage materials, electronics, and aerospace. With the continuous advancement of high-end manufacturing, the requirements for the purity, particle size distribution, and specific surface area of […]

Wax Powder: From Production Process to Application Scenarios

In the field of new materials, there exists a key additive known as the “MSG of industry” — PTFE wax powder. This white, powdery resin is produced by coagulating, washing, and drying a dispersion obtained through the controlled polymerization of tetrafluoroethylene. It possesses exceptional properties such as heat resistance, weatherability, cold resistance, low friction, non-stick […]

Jet Mill – Ultra-Fine Grinding of Heat-Sensitive Materials

Ultra-Fine Grinding is a cornerstone technology in modern manufacturing, critical to sectors like chemicals, pharmaceuticals, and food production. However, it faces unique challenges when applied to Heat-Sensitive Materials, such as certain drugs, food additives, fragrances, and polymers. These materials are prone to undesirable physical, chemical, or biological changes at elevated temperatures. Consequently, the specialized field […]

Jet Pulverizer : Key Technology for Ultra-Fine Silica Grinding

Silica micropowder can be classified based on particle morphology into angular silica micropowder and spherical silica micropowder. Angular silica micropowder is further divided into crystalline silica micropowder and fused silica micropowder based on the raw material type. Additionally, the market includes quasi-spherical silica micropowder, composite silica micropowder, and active silica micropowder. The following sections elaborate […]

The Industrial Magic of Ultrafine Powder: Defining New Standards, Driving the Future

Have you ever wondered why smartphone screens are becoming more scratch-resistant, or why cosmetics adhere more smoothly to the skin? The answer often lies in ultrafine powder.As industrial technology continues to advance, ultrafine powder has not only transformed our daily lives but has also become a key foundational material in strategic industries such as new […]

Powder Classification Technology: The Key to Precision Powder Processing

Classification technology is vital in powder material preparation. It plays a key role in powder production. In recent years, modern high-tech industries have advanced rapidly. The fine powder industry has grown quickly. Ultrafine powders are now used widely. Their applications span many fields. The demand for finer powders keeps increasing. Achieving ultrafine classification is challenging […]

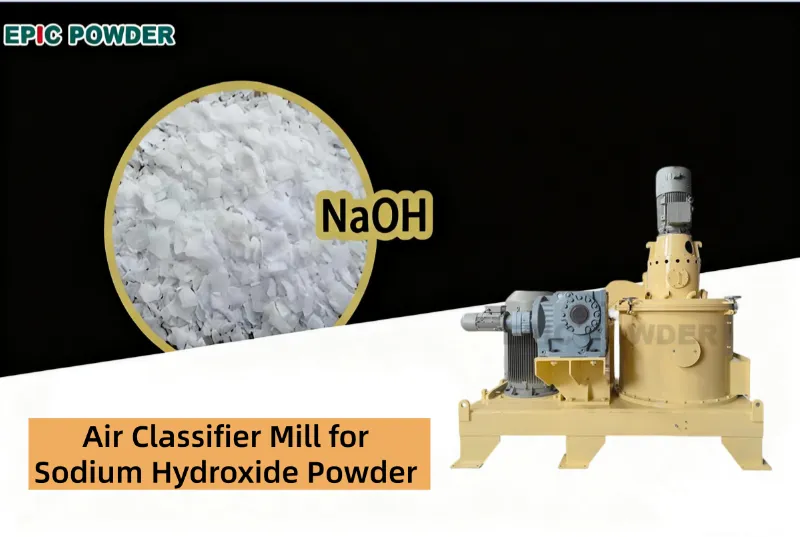

Air Classifier Mill-Advanced Sodium Hydroxide Powder Grinding Equipment

Sodium hydroxide (NaOH), commonly known as caustic soda, is a widely used and essential industrial chemical. It plays a critical role in chemical manufacturing, water treatment, as well as soap and detergent production. Although its applications are extensive, many modern industries now demand finer sodium hydroxide powders. To meet this need, the air classifier mill […]

Lithium Carbonate Jet Milling Technology – Precision Processing for High-Purity Battery Materials

Lithium carbonate (Li₂CO₃) is one of the core raw materials in the lithium battery industry chain. It is widely used in the synthesis of cathode materials for power batteries, energy storage batteries, and consumer electronics. With the rapid growth of new energy vehicles and energy storage, the requirements for Li₂CO₃ purity, particle size distribution, and […]

Polyimide Powder: The “Nano-Scale Cornerstone” of Advanced Materials

Polyimide (PI) is a class of high-performance polymers well known for their excellent thermal stability, electrical insulation, and mechanical properties, earning the title of “golden plastic.” With the development of micronization and powder processing technologies, polyimide has expanded beyond films, fibers, and coatings to include polyimide powder, further broadening its application scope, especially in composites, […]