How to choose the right Ultrafine Grinding equipment to meet the needs of different industries?

Applications in the Pharmaceutical Industry Enhancing Solubility and BioavailabilityUltrafine grinding technology reduces active pharmaceutical ingredients into submicron or nanometer-sized particles. This dramatically improves solubility and absorption efficiency, leading to faster and more consistent therapeutic effects. Improving Uniformity and StabilityBy precisely controlling particle size distribution, ultrafine grinding ensures better uniformity of pharmaceutical materials, resulting in stable […]

Silicon-Aluminum Powder delivers higher durability and lower costs for footwear and speed bumps!

As a functional powder material, silicon-aluminum powder is making its mark in various industrial fields due to its unique properties. Made from natural ores, it is produced through high-temperature sintering followed by a special grinding process. The powder primarily consists of alumina (Al₂O₃), silica (SiO₂), along with some calcium sulfate (CaSO₄), magnesium oxide (MgO), and […]

Silicon-Carbon Anode: The Key Breakthrough for the High Energy Density Era

Overview of Silicon-Carbon Anode: The Inevitable Choice Beyond Graphite Limitations Graphite Anode Reaching Its Performance Limit Currently, graphite dominates lithium battery anode materials, accounting for over 80% of the market. Its theoretical capacity is 372 mAh/g, while practical performance has already reached around 360 mAh/g — nearly the theoretical limit.However, as electric vehicles, 3C electronics, […]

Porous Carbon Pin Mill Dispersing Technology: A Key Step in Maintaining Structure and Optimizing Performance

Porous carbon has a high specific surface area, excellent conductivity, and chemical stability. It is widely used in energy storage, catalysis, adsorption, and electrochemical applications. However, powder agglomeration is a common and challenging issue during its preparation and application. To achieve uniform particle size distribution, better dispersion, and enhanced performance, Pin Mill (needle mill) dispersing […]

Potassium Sulfate Ultrafine Grinding: Application and Performance of ACM Air Classifying Mill

Potassium sulfate (K₂SO₄) is an important inorganic salt. It is widely used in fertilizers, pharmaceuticals, glass, dyes, explosives, and food additives. As a high-end potassium fertilizer, it is chlorine-free, highly soluble, and has low hygroscopicity. It is especially suitable for chloride-sensitive crops such as tobacco, tea, and fruits. With the rising quality standards in agriculture […]

Diatomaceous Earth: The “Porous Elf” of Nature

In the vast universe of chemical raw materials, there exists a gift from ancient marine life — diatomaceous earth (DE). Though it appears unremarkable, its unique properties make it an indispensable “behind-the-scenes hero” in countless industrial processes. Today, let’s uncover the secrets of this “natural filtration master” and explore how it shines in modern industry. […]

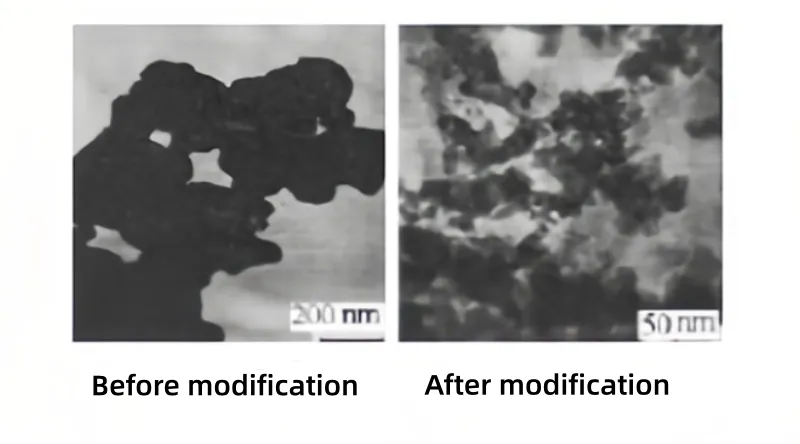

How Much Do You Know About Surface Modification of Silica?

Silica, also known as silicon dioxide, is an important inorganic chemical raw material. Due to its unique surface structure and particle morphology, silica exhibits excellent stability, reinforcing capability, thickening behavior, and thixotropy. These properties make it a crucial inorganic filler in many fields such as rubber, coatings, and plastics. However, to fully unlock its potential […]

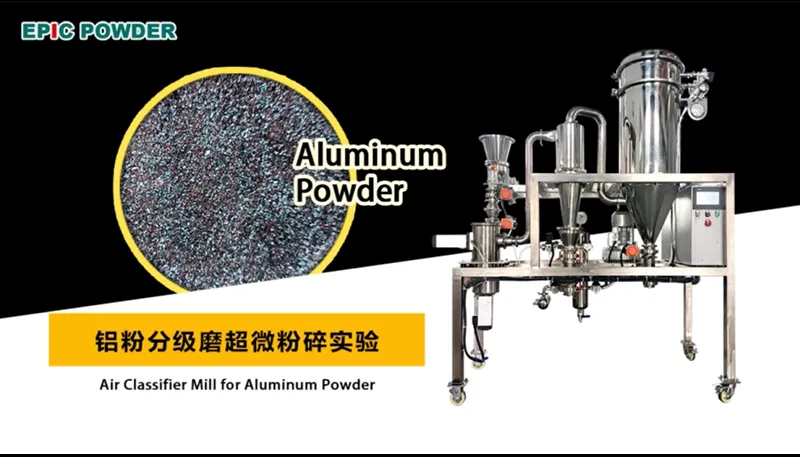

What Is High-Purity Aluminum Powder?

In high-precision manufacturing industries such as semiconductors, electronic packaging, new energy, 3D printing, and vacuum coating, high-purity aluminum powder is playing an increasingly critical role.As industries demand higher conductivity, film-forming ability, and material purity, traditional “industrial aluminum fines” can no longer meet these stringent requirements — giving rise to high-purity aluminum powder. Definition of High-Purity […]

Pin Mill for α-Hemihydrate Gypsum Grinding : The Path to High-Strength Gypsum Powder Refinement

In the fields of building materials and fine chemicals, α-hemihydrate gypsum is widely used across many industries. It offers high strength, good density, and controllable setting time, making it ideal for high-end construction materials, ceramic molds, precision casting, medical products, and crafts. To achieve superior product quality, both proper calcination and precise α-Hemihydrate Gypsum Grinding […]