高分子材料は、金属やセラミックスと並んで現代産業における三大材料システムの一つであり、日用品、電子機器、電気部品、ケーブル製造、自動車部品、建築材料など、幅広い分野で利用されています。しかし、多くの高分子は炭素鎖骨格を有しているため、加熱すると容易に分解し、可燃性ガスを発生します。その結果、裸火で容易に発火し、人体や財産の安全にとって重大な脅威となります。そのため、高分子材料を組み込むことは、 水酸化アルミニウム、 最も広く使用されているハロゲンフリー難燃剤の1つである難燃剤は、ポリマーの難燃性能を向上させるための重要なアプローチとなり、材料科学における重要な研究テーマとなっています。

ポリマーの燃焼メカニズムと難燃戦略

本質的に、ポリマーの燃焼は熱分解プロセスです。ある温度まで加熱されると、ポリマー鎖が切断され、揮発性の可燃性物質が生成されます。この物質は炎域でフリーラジカル連鎖反応を起こし、燃焼をさらに激化させます。このプロセスでは大量の熱が発生し、それが材料にフィードバックされ、継続的な熱劣化を引き起こし、悪循環を形成します。

このメカニズムに基づいて、現在の難燃戦略は主に 2 つのアプローチに焦点を当てています。

ガス相難燃性

燃焼ゾーンでのフリーラジカル連鎖反応を中断して燃焼効率を低下させます。

凝縮相難燃性

熱伝達を遮断するか、保護炭化層を形成して、熱と可燃性分解生成物が炎領域に移動するのを防ぎます。

これらの効果を実現するために、様々な難燃剤が開発されてきました。それらは、熱を吸収したり、不活性ガスを放出したり、フリーラジカルを捕捉したり、炭化を促進したりすることで作用します。 化学薬品 難燃剤はその構造上、有機系と無機系の2つに大別されます。

多くの産業が無機難燃剤へ移行している理由

ハロゲン系などの有機難燃剤の中には非常に効果的なものもありますが、熱分解生成物が毒性や環境リスクをもたらす可能性があります。環境規制がますます厳しくなるにつれ、産業界はより安全で環境に優しい無機難燃剤へと目を向けています。

無機難燃剤の利点:

- 無毒で煙の発生が少ない

- 高い熱安定性と低い化学反応性

- 比較的低コストで許容荷重レベルが高い

無機難燃剤の中で、 水酸化アルミニウム(Al(OH)₃、ATH) 最も広く使用されており、難燃剤業界では「永遠のお気に入り」とみなされています。

水酸化アルミニウムはなぜ人気があるのでしょうか?

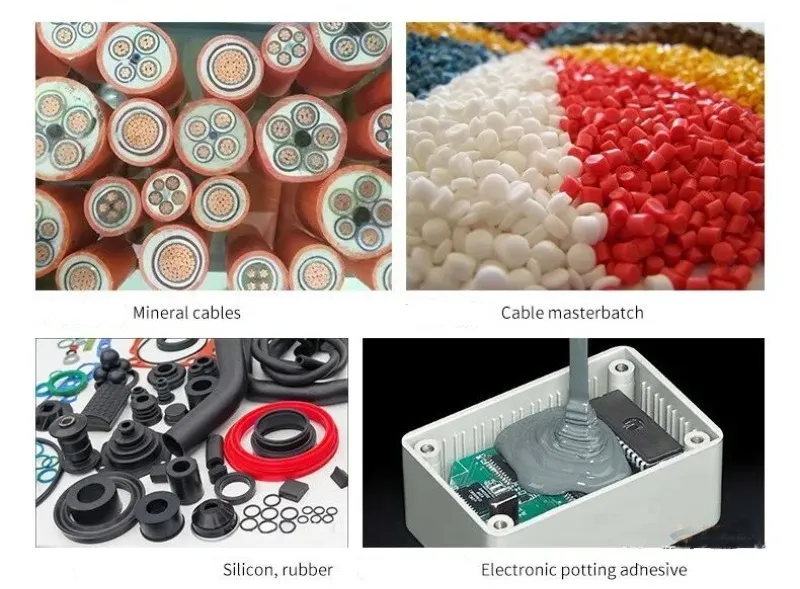

ATHは、無機難燃剤の中で最も広く利用され、最も生産量が多いため、電線・ケーブルコンパウンド、ゴム製品、熱硬化性樹脂、熱可塑性樹脂、建築材料など、ほぼすべてのポリマー難燃システムに使用されています。主な利点は以下のとおりです。

1. 強い吸熱分解(物理的な熱吸収と冷却)

ATHは約200~300℃で吸熱分解を起こします。

Al(OH)₃ → Al₂O₃ + 3H₂O↑

この反応は大量の熱を吸収し、水蒸気を放出します。これにより可燃性ガスが希釈され、燃焼が遅くなります。

2.保護アルミナ層の形成(凝縮相保護)

生成された Al₂O₃ は材料表面に緻密で安定したセラミックのような層を形成し、酸素を遮断してポリマーのさらなる熱分解を防ぎます。

3.安全、環境に優しく、費用対効果が高い

ATHは化学的に安定しており、有毒ガスを発生しません。世界的な環境規制にも適合しています。豊富な資源と低コストにより、難燃剤と機能性充填剤として理想的であり、機械特性と断熱特性を向上させながら煙の発生を抑えます。

4.非常に幅広い応用範囲

ATH は分解温度が中程度であるため、ポリオレフィン、PVC、ゴムなどの処理温度の低いポリマーに特に適しています。

一般的なアプリケーションは次のとおりです:

- ワイヤーとケーブル: 50%~65% ATH搭載の低煙ハロゲンフリーケーブルコンパウンド

- 建材: 断熱ボード、難燃性アルミ複合パネル、地下鉄・トンネル複合材

- 自動車・輸送: EVバッテリーパック材料、内装部品、鉄道輸送部品

- 電子機器および家電製品: PCBラミネート、家電ハウジング、プラグ、ソケット

- ゴム製コンベアベルト: 鉱業用難燃性帯電防止ベルト

水酸化アルミニウムにも欠点はあります。

主な欠点は次のとおりです。

- 高い荷重レベル(UL94 V-0では通常40%~65%)により、機械的強度とメルトフローが低下する可能性があります。

- 親水性が高く、疎水性ポリマーとの相溶性が低いため、表面処理(シラン、チタン酸塩、ステアリン酸など)が必要です。

しかし、超微粉砕(D50 < 2 μm)、表面改質、ナノATH、水酸化マグネシウムとの相乗効果などの進歩により、これらの問題は大幅に緩和されました。

水酸化アルミニウムの製造および粉砕技術:

難燃性システムにおけるATHの性能は、その 粒子サイズ、粒度分布、比表面積、表面特性など、様々な要素が重要です。そのため、高品質のATHは、安定した高精度の粉砕・分級プロセスに依存します。

1. 原材料の供給源と前処理

工業用ATHは通常、バイエル法で製造されます。原料のATH粒子は凝集体を形成し、比較的大きな粒子径を示すことが多いため、ポリマーシステムの性能要件を満たすには、更なる粉砕が必要です。

2. 研削装置 選択:粒子サイズ制御の鍵

用途に応じて粒子サイズも異なります。

- ケーブルコンパウンド: D50 = 1~10μm

- コーティング剤/接着剤: より細かいグレード

- ハイエンドマスターバッチ: D97 < 10 μm、狭い粒度分布

一般的な研削ソリューションには次のようなものがあります。

ボールミル+空気分級システム

- D50 1~8μm ATHの大規模かつ安定した生産に最適

- 精密な粒子サイズ制御により、D97 10~15μmを実現

- PVC、PP、ケーブルコンパウンドに広く使用されています

- 粒子形状と分散性の改善

ジェットミル(エアジェットミル)

- 高速気流を使用して超微細衝撃研削を行う

- D97 3~5μmまたはそれより微細なスーパーミクロン粉末を製造

- エンジニアリングプラスチック、透明材料、光学グレードの配合に適しています

- 培地汚染がなく、高純度を保証

垂直ローラーミル、 ピンミル、インパクトミル

- 中粒度グレード(D50 5~30μm)に適しています

- 建築資材やゴム製品に使用される

- より高い生産量、より低い運用コスト

3. 分類技術: 狭いPSDと高い安定性を確保

高精度タービンまたはマルチホイール分級機は微粒子と粗粒子を分離し、ATH に次の機能を提供します。

- 狭い粒度分布

- ポリマー溶融体のシステム粘度の低下

- 均一分散

- より安定した効率的な難燃性能

特に高荷重ケーブルコンパウンドでは、粒子サイズの安定性が機械的特性と押し出し性能に直接影響します。

4. 表面改質: ポリマーマトリックスとの適合性の向上

PP や PE などの非極性ポリマーは無機充填剤との相溶性が低いため、表面処理が不可欠です。

一般的なカップリング剤

- チタン酸塩

- シラン

- アルミン酸塩

変更プロセス

連続改質剤+高せん断混合

利点

- 溶融粘度が低い

- より良い分散

- 許容充填量の増加

- 機械的特性の向上

ワイヤーとケーブルのコンパウンドでは、高品質のATHは表面処理を施さなければなりません。 コーティング 優れた加工安定性と電気絶縁性能を実現します。

結論

ポリマーの難燃性能の向上は、長期的かつ重要な課題です。数ある難燃剤の中でも、水酸化アルミニウムは、吸熱性、放水性、保護層形成性、安全性、そして環境への配慮において際立っています。水酸化アルミニウムは、ますます厳しくなる規制を満たしながら難燃性レベルを向上させるため、ケーブル、建設、自動車、電子機器など、幅広い用途で使用されています。

難燃性技術が進化するにつれ、ATH は、特に高効率配合、相乗システム、精密アプリケーションにおいて、引き続き重要な役割を果たします。

エピックパウダー ATH 生産のための包括的な処理ソリューションを提供します。これには以下が含まれます。

EPIC Powder は、正確な粒子サイズの制御、低汚染粉砕、効率的な改質により、ケーブルコンパウンド、ゴム、建設資材、エンジニアリングプラスチック用の安定した高性能 ATH を実現します。

読んでいただきありがとうございます。この記事がお役に立てれば幸いです。ぜひ下のコメント欄にご意見をお寄せください。また、ご質問等ございましたら、Zeldaのオンラインカスタマーサポートまでお問い合わせください。

— 投稿者 エミリー・チェン