Fallübersicht

| Artikel | Beschreibung |

|---|---|

| Kunde / Standort | Ein bekannter Hersteller von Hochleistungsmetallpulvern in Thailand |

| Material | Eine Art Hochleistungslegierungsmetallpulver |

| Gerätetyp | Spiralstrahlmühle |

| Kernherausforderung | Erreichen einer ultrafeinen Metallpulverklassifizierung mit einer extrem engen Partikelgröße Distribution in etal Powder Processing, um die strengen Qualitätsanforderungen der fortschrittlichen Fertigung (wie additive Fertigung/3D-Druck oder Metallspritzguss) zu erfüllen. |

| Ziel | Endprodukt-Partikelgröße D99,9 ≤ 8 μm |

Herausforderungen und Anforderungen

Mit dem rasanten Wachstum der globalen Hightech-Fertigung – insbesondere der weitverbreiteten Anwendung additiver Fertigungsverfahren (3D-Druck) – sind die Anforderungen an Pulverreinheit, Kugelform und Partikelgrößenverteilung so hoch wie nie zuvor. Als führender Lieferant von Hochleistungsmetallpulvern in der Region stand der thailändische Kunde vor mehreren zentralen Herausforderungen:

- Extrem hohe Feinheitsanforderungen

Der angestrebte Partikelgrößenindex lag bei D99 ≤ 8 μm oder sogar feiner. Dies bedeutet, dass 99,91 % der Partikel kleiner als 8 μm sein müssen, was eine außergewöhnlich präzise Klassifizierung erfordert. - Kombinierter Bedarf an effektiver Deagglomeration und Klassifizierung

Metallpulver neigen zur Agglomeration. Für eine effektive Deagglomeration ist ein hoher Energieaufwand erforderlich, und eine genaue Klassifizierung muss folgen, um zu verhindern, dass zu große Partikel in das Endprodukt gelangen. - Erhaltung der Materialeigenschaften

Der Mahl- und Klassierprozess muss die Auswirkungen auf die Pulvermorphologie minimieren und chemisch Reinheit, wobei die dem Material innewohnenden Hochleistungseigenschaften erhalten bleiben.

Die Lösung von Episches Pulver

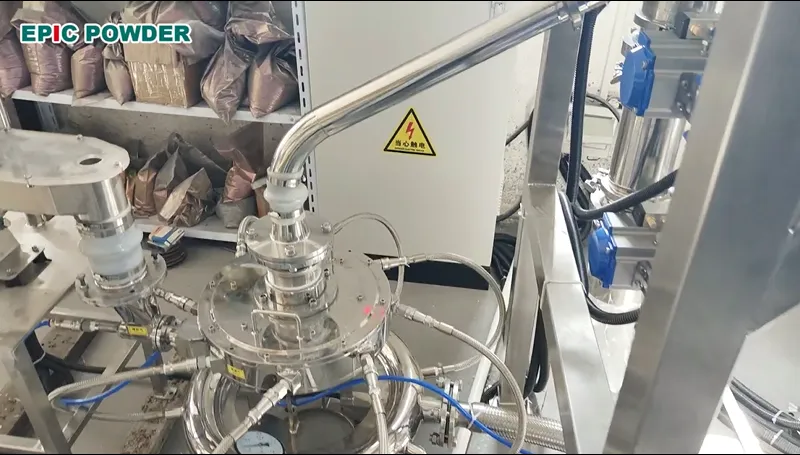

Um diesen Herausforderungen zu begegnen, empfahl und implementierte Epic Powder Folgendes: Spiralstrahlmühle–basiertes ultrafeines Metallpulververarbeitungssystem.

1. Erste Entagglomeration und Vorklassifizierung — Spiralstrahlmühle

- Funktion:

Die Spiralstrahlmühle erzeugt einen Hochgeschwindigkeits-Luftstrom, der im Inneren der Mahlkammer einen Überschallwirbel bildet. In diesem Wirbel stoßen die Partikel aufeinander und reiben aneinander, was zu einer effizienten Entklumpung und Vormikronisierung führt. - Vorteile:

Die integrierte dynamische Klassierzone entfernt effektiv die meisten groben Partikel, wodurch die Belastung der nachfolgenden Klassieranlage reduziert und Verunreinigungen durch mechanischen Kontakt vermieden werden.

2. Präzise Ultrafeinklassifizierung

Nach der Vorbehandlung durch die Spiralstrahlmühle wird die Feinklassierung durch Anpassen des Luftdrucks und der Drehzahl des Klassierrades erreicht.

Dieses System zersetzt Agglomerate gründlich und entfernt übergroße Partikel, wodurch eine sehr enge Partikelgrößenverteilung gewährleistet wird, die den strengen D99-Anforderungen entspricht.

Umsetzungsergebnisse

Nach der Inbetriebnahme und mehreren Optimierungsrunden erfüllte das System erfolgreich die strengen Vorgaben des Kunden hinsichtlich der Partikelgröße des Metallpulvers:

| Leistungskennzahlen | Ziel | Tatsächlich | Auswertung |

|---|---|---|---|

| D99 | ≤ 8 μm | 7,58 μm | Ziel übertroffen |

| Partikelgrößenverteilung | Sehr schmal | Weltklasse-Standard erreicht | Deutliche Verbesserung |

| Produktausbeute | Hohes Niveau beibehalten | >95% | Hohe Wirtschaftlichkeit |