Serbuk ultrahalus biasanya ditakrifkan sebagai serbuk dengan a saiz Zarah kurang daripada 10μm. Dengan kemajuan sains dan teknologi, banyak industri memerlukan bahan pepejal dalam bentuk serbuk.

Serbuk yang diperlukan mestilah mempunyai saiz zarah yang kecil, ketulenan tinggi, dan tiada kekotoran. Terdapat juga keperluan khusus untuk pengedaran saiz zarah serbuk. Akibatnya, teknologi dan peralatan pengisaran ultrahalus semakin digunakan secara meluas. Penyelidik memberi lebih perhatian kepada dan menumpukan pada teknologi dan peralatan pengisaran ultrahalus. Kilang jet udara teknologi adalah kaedah penting untuk penyediaan serbuk ultrafine. Ia telah menjadi salah satu kaedah pilihan untuk membangunkan pelbagai bahan serbuk mikro berprestasi tinggi.

Ciri-ciri Kilang Jet Udara

The kilang jet udara, juga dikenali sebagai kilang udara atau kilang katil terbendalir, menggunakan aliran udara berkelajuan tinggi. Aliran udara ini menyebabkan perlanggaran, hentaman dan daya ricih antara bahan dan komponen hentaman. Produk yang diperoleh melalui kilang jet udara mempunyai saiz zarah yang seragam, pengedaran sempit, ketulenan tinggi, dan permukaan licin. Zarah mempunyai bentuk yang tetap dan keterserakan yang baik.

Semasa proses pengisaran, bahan mengalami pencemaran yang minimum, malah ia boleh dilakukan dalam persekitaran yang bebas pencemaran dan steril. Oleh itu, ia sesuai untuk pengisaran ultrahalus dalam bidang seperti makanan dan farmaseutikal, di mana pencemaran tidak dibenarkan. Kilang jet udara tidak melepaskan sejumlah besar haba semasa proses pengisaran, menjadikannya lebih sesuai untuk mengisar bahan lebur rendah atau sensitif haba. Proses pengeluaran mempunyai tahap automasi yang tinggi dan sesuai untuk pengeluaran perindustrian berskala besar.

Pemakaian Kilang Jet Udara

Dalam bidang ketenteraan dan aeroangkasa, bahan serbuk ultrahalus digunakan untuk mengeluarkan bahan siluman untuk pesawat dan kereta kebal siluman. Propelan roket yang diperbuat daripada pengoksida dan pemangkin giling jet udara mempunyai kadar pembakaran lebih daripada dua kali ganda berbanding konvensional.

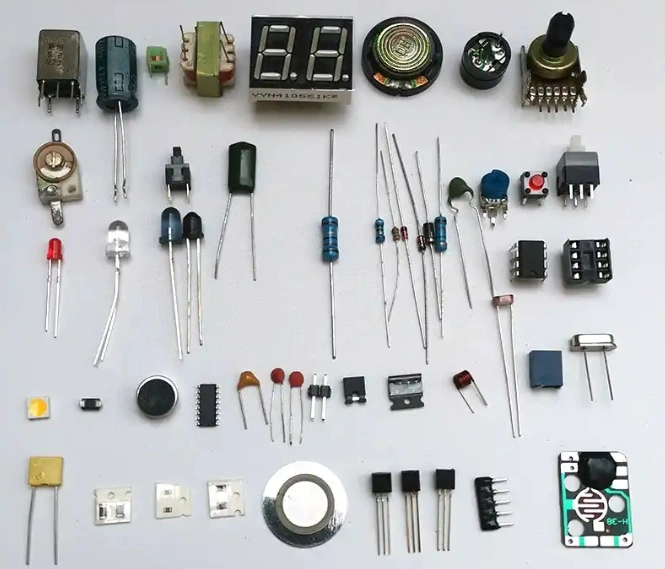

Dalam bidang elektronik, serbuk oksida besi ultrahalus boleh digunakan untuk menghasilkan bahan magnet berprestasi tinggi. Serbuk silika ultrahalus boleh digunakan untuk menghasilkan bahan perintang berprestasi tinggi. Serbuk alumina ketulenan ultratinggi boleh digunakan untuk mengeluarkan substrat nilam untuk cip LED. Substrat yang diperbuat daripada serbuk ultrafine mempunyai kestabilan yang baik, ketelusan, dan tidak menyerap cahaya yang boleh dilihat. Selepas kilang jet udara, serbuk molibdenum mempunyai saiz zarah yang lebih kecil, pengedaran lebih sempit, dan ketumpatan pukal dan pili yang lebih baik. Ini menjadikannya lebih sesuai untuk menghasilkan mentol lampu, tiub elektron dan litar bersepadu.

Dalam bidang tenaga baharu, bahan yang diproses oleh kilang jet udara mempunyai saiz zarah purata halus, pengedaran sempit, permukaan licin, bentuk biasa, ketulenan tinggi, kereaktifan tinggi, dan kebolehserakan yang baik. Sifat-sifat ini memenuhi keperluan penyediaan untuk bahan elektrod, yang membawa kepada penggunaan yang meluas. Bahan biasa yang sesuai untuk kilang jet udara termasuk: litium mangan oksida, litium kobalt oksida, litium besi fosfat, litium karbonat, grafit sfera, kok petroleum, kok asfalt, bahan terner, aloi hidrida nikel-logam, ferus oksalat, litium titanat, dan litium nikel mangan oksida.

Kesimpulan

Teknologi kilang jet udara ialah kaedah penting untuk memproses serbuk bersaiz mikro dan nanometer. Penyelidikan dan pembangunannya boleh meningkatkan kecekapan penggunaan sumber dengan ketara. Memandangkan permintaan untuk serbuk halus dan ultrahalus terus meningkat, pengilangan jet udara teknologi menawarkan penyelesaian yang mampan dan cekap untuk memaksimumkan hasil bahan sambil mengekalkan kualiti produk.

Bedak Epik

Serbuk Epik, 20+ tahun pengalaman kerja dalam industri serbuk ultrahalus. Secara aktif menggalakkan pembangunan serbuk ultra-halus masa hadapan, memfokuskan pada proses penghancuran, pengisaran, pengelasan dan pengubahsuaian serbuk ultra-halus. Hubungi kami untuk perundingan percuma dan penyelesaian tersuai! Pasukan pakar kami berdedikasi untuk menyediakan produk dan perkhidmatan berkualiti tinggi untuk memaksimumkan nilai pemprosesan serbuk anda. Serbuk Epik—Pakar Pemprosesan Serbuk Dipercayai Anda!