Silice, noto anche come biossido di silicio, è un importante inorganico chimico Materia prima. Grazie alla sua esclusiva struttura superficiale e alla morfologia delle particelle, la silice presenta un'eccellente stabilità, capacità di rinforzo, comportamento addensante e tissotropia. Queste proprietà la rendono un riempitivo inorganico fondamentale in molti campi come la gomma, i rivestimenti e le materie plastiche. Tuttavia, per sfruttarne appieno il potenziale e migliorare la compatibilità con diverse matrici organiche, è necessario... modifica della superficie di silice. Questo processo è fondamentale per adattarne le proprietà a specifiche applicazioni.

Modifica della superficie di silice

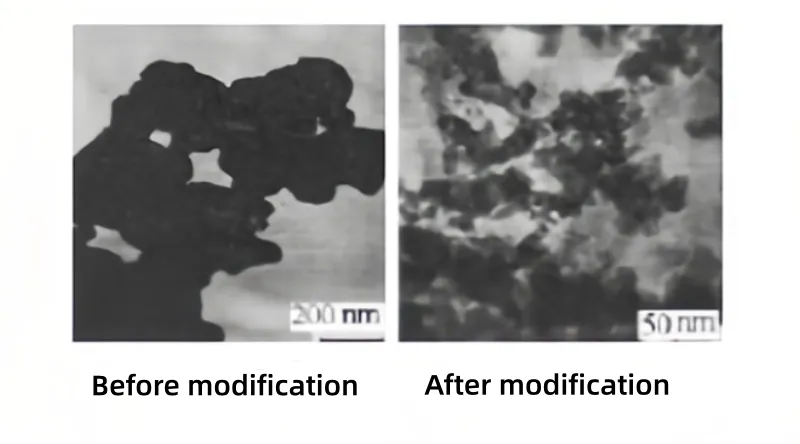

La struttura interna del polisilossano e i gruppi silanolo tensioattivi rendono la silice precipitata altamente idrofila, con conseguente scarsa bagnabilità e disperdibilità nelle fasi organiche. I gruppi ossidrilici sulla superficie contribuiscono a un'elevata energia superficiale, causando agglomerazione che influisce sulle prestazioni del prodotto. Durante la produzione, ciò porta ad aggregazione, idrofilia, costi elevati, bassa efficienza e un elevato consumo energetico. In considerazione delle crescenti pressioni ambientali, la riduzione dei costi, il miglioramento dell'efficienza e il miglioramento dell'idrofobicità superficiale sono diventati particolarmente importanti.

Sulla superficie della silice sono presenti tre tipi di gruppi idrossilici:

- Gruppi idrossilici isolati, che sono liberi e non influenzati;

- Gruppi idrossilici geminali, dove due idrossili sono legati allo stesso atomo di silicio;

- Gruppi idrossilici associati, che sono legati tra loro tramite legami idrogeno.

Superficie modifica della silice comporta l'uso di un modificatore che reagisce chimicamente con questi gruppi idrossilici superficiali per rimuovere o ridurre i gruppi silanolo, alterando così le proprietà superficiali.

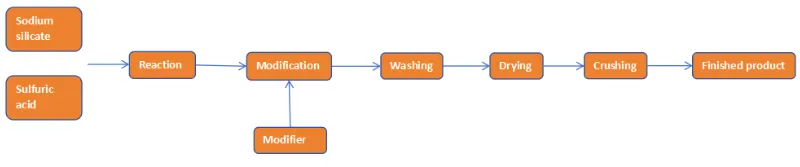

Processi di modifica della superficie

In base alla natura del modificatore, la modifica della superficie può essere classificata in organico E inorganico Modifiche. Tra queste, la modifica organica è la più utilizzata. La tecnologia chiave per la modifica organica è il trattamento organosilano, in cui i gruppi funzionali organici sostituiscono i gruppi ossidrilici sulla superficie della silice.

I metodi di modificazione organica sono generalmente suddivisi in metodi a secco, a umido e a calore pressurizzato. Attualmente, i paesi sviluppati utilizzano principalmente il metodo a secco per modificare la silice pirogenica.

Vantaggi del metodo a secco:

- Processo semplice con meno fasi di post-trattamento.

- Facile integrazione con il processo di produzione della silice pirogenica.

- Adatto alla produzione industriale su larga scala.

Svantaggi del metodo a secco:

- Elevato consumo di modificatore.

- Richiede elevati standard di attrezzatura e rigorose condizioni operative.

- Costi di produzione relativamente elevati.

IL metodo di modifica a umido è anch'esso comunemente utilizzato e comprende principalmente due approcci:

Vantaggi del metodo a umido:

- Minore consumo di modificatori.

- Processo semplice e minori requisiti di attrezzatura.

- Costi di produzione inferiori e migliore controllo della qualità.

Svantaggi del metodo a umido:

- Processo di post-trattamento complesso.

- Problemi di inquinamento ambientale.

- Difficile da adattare alla produzione industriale di massa.

Un altro approccio di modifica a umido prevede modifica in situ durante il processo di precipitazione della silice, che può migliorare l'efficienza e l'integrazione.

Modificatori comuni e principi di modifica

Tra i modificatori più comuni figurano silani organici alogenati, agenti accoppianti silanici, sililammine, silossani e composti alcolici. Questi reagenti si legano chimicamente o sostituiscono i gruppi ossidrilici superficiali della silice, migliorando così l'idrofobicità, la disperdibilità e la compatibilità con i materiali organici.

Applicazioni della silice modificata

La silice modificata è un importante agente rinforzante nei prodotti in gomma, colmando il divario in cui nero di carbonio Non può essere utilizzato in materiali di colore chiaro. Nella produzione di pneumatici, l'aggiunta di silice modificata migliora la resistenza meccanica della gomma, riduce la perdita per isteresi, diminuisce la resistenza al rotolamento e mantiene un'eccellente aderenza sul bagnato.

Nei sigillanti e negli adesivi, la silice modificata migliora la disperdibilità, la compatibilità e la durata del prodotto. Nei rivestimenti, la silice funge da comune agente opacizzante; l'uso di silice modificata ne migliora la dispersione e riduce i problemi di aggregazione o sedimentazione.

Rispetto alla silice comune, la silice modificata offre prestazioni complessive migliori e un campo di applicazione più ampio.

Conclusione

La silice modificata non solo mantiene le eccellenti proprietà della silice tradizionale, ma presenta anche una maggiore idrofobicità e caratteristiche superficiali migliorate. Questo ne amplia notevolmente il potenziale applicativo. Con il continuo sviluppo economico, la domanda di mercato di silice modificata continua a crescere. Lo sviluppo di tecnologie di produzione su larga scala, ecocompatibili e convenienti per la silice modificata è diventato un obiettivo chiave per i produttori di silice in futuro.