Hidróxido de alumínio (ATH) é um pó branco amorfo. É um hidróxido anfotérico. Hidróxido de alumínio ultrafino É estável à temperatura ambiente. Não produz poluição secundária durante a combustão. Possui alta brancura e excelentes propriedades de cor.

O ATH nanométrico aumenta o índice de oxigênio limitante dos polímeros retardantes de chama. Melhora a retardância à chama. Melhora a lisura da superfície, a resistência mecânica e as propriedades elétricas. Melhora a resistência à corrente de fuga, a resistência ao arco e a resistência ao desgaste.

O ATH funciona bem quando combinado com outros retardantes de chama. É sinérgico, não volátil, não tóxico e não corrosivo. É abundante e de baixo custo. Portanto, é amplamente utilizado como retardante de chama inorgânico.

Vantagens dos retardantes de chama de hidróxido de alumínio

O hidróxido de alumínio ultrafino permanece estável em suas propriedades físicas e químico Propriedades à temperatura ambiente, não produz poluição secundária durante a combustão e oferece alta brancura com excelente desempenho de cor. O hidróxido de alumínio nanométrico não apenas aumenta o índice de oxigênio limitante dos polímeros, melhorando a retardância à chama, mas também melhora a lisura da superfície do polímero e o desempenho mecânico e elétrico. Ele fortalece a resistência à corrente de fuga, a resistência ao arco e a resistência ao desgaste. Além disso, o hidróxido de alumínio apresenta efeitos sinérgicos ideais quando usado em combinação com outros retardantes de chama. É não volátil, atóxico, não corrosivo, abundante e econômico, tornando-se um retardante de chama inorgânico amplamente aplicado.

Métodos de preparação de micropós ultrafinos de hidróxido de alumínio

Método Físico

A preparação geral do pó de hidróxido de alumínio pode ser realizada por métodos físicos e químicos. O método físico envolve a trituração de blocos ou grânulos de ATH usando moinho de bolass, moinhos de vibração ou moinho a jatos. O material é dividido em partículas mais finas por deformação e fratura, seguida de modificação da superfície para melhorar o desempenho, se necessário. Este processo geralmente utiliza partículas grossas de hidróxido de alumínio de plantas de alumina como matéria-prima, que são então processadas por moagem a jato dispersão e classificação do ar para obter ATH ultrafino. O método físico apresenta baixo custo, alto rendimento e processamento simples. No entanto, o tamanho da partícula A distribuição é relativamente ampla (tipicamente 5–15 μm), a morfologia das partículas é irregular e a brancura e a pureza dependem do material de ATH bruto. Portanto, é adequado para aplicações onde os requisitos de pureza, tamanho de partícula e morfologia não são muito rigorosos.

Métodos Químicos

- Método de semeadura

O método de semeadura envolve a adição de sementes ultrafinas de ATH a uma solução preparada de aluminato de sódio para obter pós de ATH mais finos e puros. A qualidade dos cristais de semente é um fator-chave que influencia a distribuição do tamanho das partículas. - Método Sol-Gel

Este método hidrolisa compostos de alumínio sob temperatura de banho, velocidade de agitação e pH controlados para formar um colóide de ATH, que é então convertido em um gel. Após secagem e moagem, são obtidos pós de ATH ultrafinos com tamanho de partícula menor. - Método de Precipitação

Os métodos de precipitação incluem precipitação direta e precipitação homogêneaA precipitação direta envolve a adição de um precipitante a uma solução de aluminato sob condições controladas para produzir ATH ultrafino de alta pureza. A eficiência da mistura do precipitante e da solução é fundamental para as propriedades do produto final. A precipitação homogênea difere da precipitação direta, pois a taxa de precipitação é mais gradual, resultando em diferentes características do pó. - Método Hidrotermal

Na síntese hidrotérmica, as matérias-primas reagem em um meio solvente orgânico em alta temperatura e pressão dentro de um recipiente de reação selado para produzir pós de ATH. - Método de carbonatação

O método de carbonatação introduz CO₂ em uma solução de aluminato de sódio. Controlando as condições de reação, é possível produzir ATH ultrafino.

Pó épico

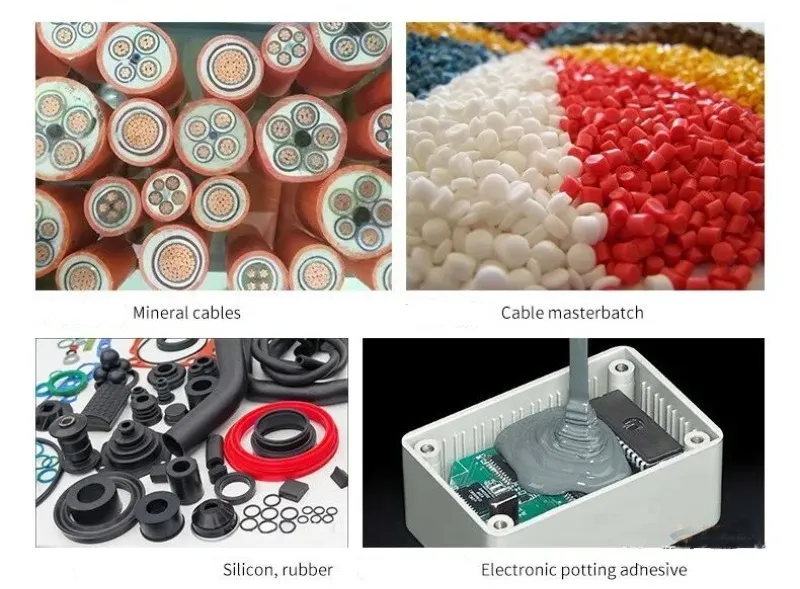

Como um importante retardante de chamas, o hidróxido de alumínio ultrafino é cada vez mais procurado em plásticos, borracha, cabos, revestimentos e outras indústrias. Alcançar qualidade estável e tamanhos de partículas ultrafinas requer tecnologia avançada de processamento de pó. A Epic Powder, com mais de 20 anos de experiência em moagem e classificação ultrafinas, fornece soluções personalizadas utilizando moinhos de bolas, moinhos a jato, classificadores de ar e equipamentos de modificação de superfície. Com tecnologia confiável e expertise profissional, a Epic Powder garante a produção eficiente e precisa de micropós de ATH de alto desempenho, ajudando os clientes a maximizar o valor do produto no competitivo mercado de retardantes de chamas.