Panoramica del caso

| Articolo | Descrizione |

|---|---|

| Cliente / Posizione | Un noto produttore di polvere metallica ad alte prestazioni in Thailandia |

| Materiale | Un tipo di polvere metallica in lega ad alte prestazioni |

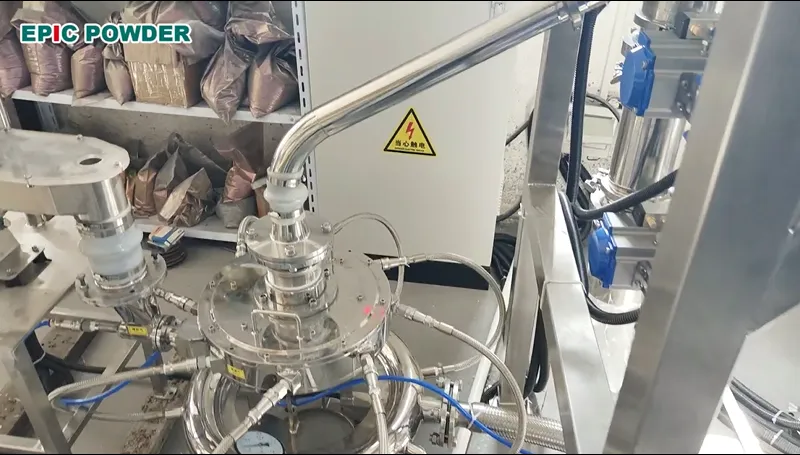

| Tipo di apparecchiatura | Mulino a getto a spirale |

| Sfida fondamentale | Ottenere una classificazione della polvere metallica ultrafine con un'estremamente stretta dimensione delle particelle distribuzione in etal Powder Processing per soddisfare i severi requisiti di qualità della produzione avanzata (come la produzione additiva/stampa 3D o lo stampaggio a iniezione di metalli). |

| Bersaglio | Dimensione delle particelle del prodotto finale D99,9 ≤ 8 μm |

Sfide e requisiti

Con la rapida crescita della produzione avanzata a livello globale, in particolare con l'adozione diffusa della produzione additiva (stampa 3D), i requisiti di purezza, sfericità e distribuzione granulometrica delle polveri sono diventati più stringenti che mai. In qualità di fornitore leader di polveri metalliche ad alte prestazioni nella regione, il cliente thailandese ha dovuto affrontare diverse sfide chiave:

- Requisito di finezza estremamente elevato

L'indice granulometrico target era D99 ≤ 8 μm o anche più fine. Ciò significa che il 99,9% di particelle deve essere inferiore a 8 μm, il che richiede prestazioni di classificazione eccezionalmente precise. - Necessità combinata di deagglomerazione e classificazione efficaci

Le polveri metalliche tendono ad agglomerarsi facilmente. Per una deagglomerazione efficace è necessario un forte apporto energetico, a cui deve seguire un'accurata classificazione per evitare che particelle di grandi dimensioni entrino nel prodotto finale. - Mantenimento delle proprietà dei materiali

Il processo di macinazione e classificazione deve ridurre al minimo l'impatto sulla morfologia della polvere e chimico purezza, preservando le caratteristiche intrinseche di elevate prestazioni del materiale.

La soluzione di Polvere epica

Per affrontare queste sfide, Epic Powder ha raccomandato e implementato un mulino a getto a spirale–sistema di lavorazione di polvere metallica ultrafine basato su.

1. Deagglomerazione iniziale e pre-classificazione — Mulino a getto a spirale

- Funzione:

Il mulino a getto a spirale genera un flusso d'aria ad alta velocità che crea un vortice supersonico all'interno della camera di macinazione. In questo vortice, le particelle si scontrano e sfregano tra loro, determinando un'efficiente deagglomerazione e una micronizzazione preliminare. - Vantaggi:

La sua zona di classificazione dinamica integrata rimuove efficacemente la maggior parte delle particelle grossolane, riducendo il carico sulla classificazione a valle ed eliminando la contaminazione da contatto meccanico.

2. Classificazione ultrafine precisa

Dopo il pretrattamento mediante mulino a getto a spirale, si ottiene una classificazione fine regolando la pressione dell'aria e la velocità della ruota classificatrice.

Questo sistema scompone in modo completo gli agglomerati e rimuove le particelle di grandi dimensioni, garantendo una distribuzione granulometrica molto ristretta che soddisfa i rigorosi requisiti D99.

Risultati dell'implementazione

Dopo la messa in servizio e diversi cicli di ottimizzazione, il sistema ha soddisfatto con successo le rigorose specifiche del cliente in materia di dimensioni delle particelle di polvere metallica:

| Indice di prestazione chiave | Bersaglio | Attuale | Valutazione |

|---|---|---|---|

| D99 | ≤ 8 μm | 7,58 μm | Obiettivo superato |

| Distribuzione granulometrica delle particelle | Molto stretto | Raggiunto standard di livello mondiale | Miglioramento significativo |

| Resa del prodotto | Mantenere un livello elevato | >95% | Alta efficienza economica |