Descripción general del caso

| Artículo | Descripción |

|---|---|

| Cliente / Ubicación | Un conocido fabricante de polvo metálico de alto rendimiento en Tailandia |

| Material | Un tipo de polvo metálico de aleación de alto rendimiento. |

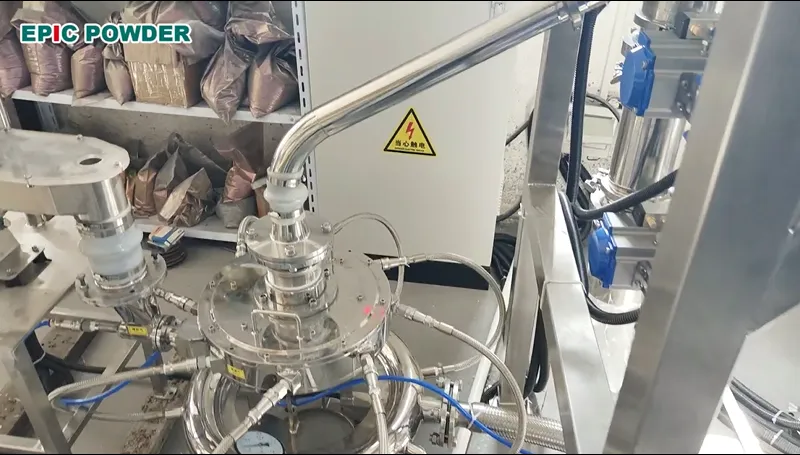

| Tipo de equipo | Molino de chorro en espiral |

| Desafío central | Conseguir una clasificación de polvo metálico ultrafino con un ancho de banda extremadamente estrecho tamaño de partícula Distribución en el procesamiento de polvos metálicos para cumplir con los estrictos requisitos de calidad de la fabricación avanzada (como fabricación aditiva/impresión 3D o moldeo por inyección de metal). |

| Objetivo | Tamaño de partícula del producto final D99,9 ≤ 8 μm |

Desafíos y requisitos

Con el rápido crecimiento de la fabricación avanzada a nivel mundial, especialmente la adopción generalizada de la fabricación aditiva (impresión 3D), los requisitos de pureza, esfericidad y distribución del tamaño de partícula del polvo se han vuelto más exigentes que nunca. Como proveedor líder de polvo metálico de alto rendimiento en la región, el cliente tailandés se enfrentó a varios desafíos clave:

- Requisito de finura extremadamente alto

El índice de tamaño de partícula objetivo fue D99 ≤ 8 μm o incluso más fino. Esto significa que el 99,91 TP3T de las partículas debe ser inferior a 8 μm, lo que requiere una clasificación excepcionalmente precisa. - Necesidad combinada de desaglomeración y clasificación efectivas

Los polvos metálicos tienden a aglomerarse fácilmente. Se requiere un alto aporte de energía para una desaglomeración eficaz, y es necesario realizar una clasificación precisa para evitar que partículas de gran tamaño entren en el producto final. - Mantenimiento de las propiedades del material

El proceso de molienda y clasificación debe minimizar el impacto en la morfología del polvo y químico pureza, preservando las características inherentes de alto rendimiento del material.

La solución de Polvo épico

Para abordar estos desafíos, Epic Powder recomendó e implementó un Molino de chorro espiral–sistema de procesamiento de polvo metálico ultrafino basado en.

1. Desaglomeración inicial y preclasificación — Molino de chorro en espiral

- Función:

El molino de chorro espiral genera un flujo de aire de alta velocidad que forma un vórtice supersónico dentro de la cámara de molienda. En este vórtice, las partículas colisionan y se frotan entre sí, lo que resulta en una desaglomeración eficiente y una micronización preliminar. - Ventajas:

Su zona de clasificación dinámica incorporada elimina eficazmente la mayoría de las partículas gruesas, reduciendo la carga en la clasificación posterior y eliminando la contaminación por contacto mecánico.

2. Clasificación ultrafina precisa

Después del pretratamiento mediante el molino de chorro espiral, se logra una clasificación fina ajustando la presión del aire y la velocidad de la rueda clasificadora.

Este sistema descompone completamente los aglomerados y elimina las partículas de gran tamaño, lo que garantiza una distribución de tamaño de partícula muy estrecha que cumple con los estrictos requisitos D99.

Resultados de la implementación

Después de la puesta en marcha y varias rondas de optimización, el sistema cumplió con éxito las estrictas especificaciones del cliente en cuanto al tamaño de partículas de polvo metálico:

| Índice de rendimiento clave | Objetivo | Actual | Evaluación |

|---|---|---|---|

| D99 | ≤ 8 micras | 7,58 micras | Objetivo superado |

| Distribución del tamaño de partículas | Muy estrecho | Alcanzó el estándar de clase mundial | Mejora significativa |

| Rendimiento del producto | Mantener un nivel alto | >95% | Alta eficiencia económica |