En los campos de los materiales de construcción y la química fina, el yeso α-hemihidratado se utiliza ampliamente en diversas industrias. Ofrece alta resistencia, buena densidad y un tiempo de fraguado controlable, lo que lo hace ideal para materiales de construcción de alta gama, moldes cerámicos, fundición de precisión, productos médicos y artesanía. Para lograr una calidad superior del producto, se requiere una calcinación adecuada y una precisión... Yeso α-hemihidratado La molienda es esencial. El proceso de molienda influye directamente en la finura del polvo, la uniformidad de las partículas y la consistencia del rendimiento. Por lo tanto, se requiere una molienda eficiente y estable. equipo de molienda — como el Molino de pasadores — juega un papel vital en la producción de polvo de yeso α-hemihidratado refinado y de alta calidad.

Introducción al yeso α-hemihidratado

Yeso α-hemihidratado Se obtiene calcinando yeso natural (CaSO₄·2H₂O) en condiciones de alta temperatura y presión, lo que provoca su deshidratación. En comparación con el yeso β-hemihidratado convencional, el tipo α tiene cristales columnares o de columna corta, mayor densidad de cristales y menor porosidad, con las siguientes características:

- Alta resistencia: La resistencia a la compresión puede alcanzar los 40-60 MPa;

- Uniforme tamaño de partícula y buena fluidez;

- Baja contracción después del moldeo y excelente estabilidad dimensional;

- Ideal para productos de yeso de alta gama, como compuestos autonivelantes, placas de yeso de alta resistencia, moldes de cerámica, componentes médicos y decorativos.

Por lo tanto, la calidad del polvo de yeso α-hemihidrato determina directamente las propiedades mecánicas y la calidad de la superficie del producto final.

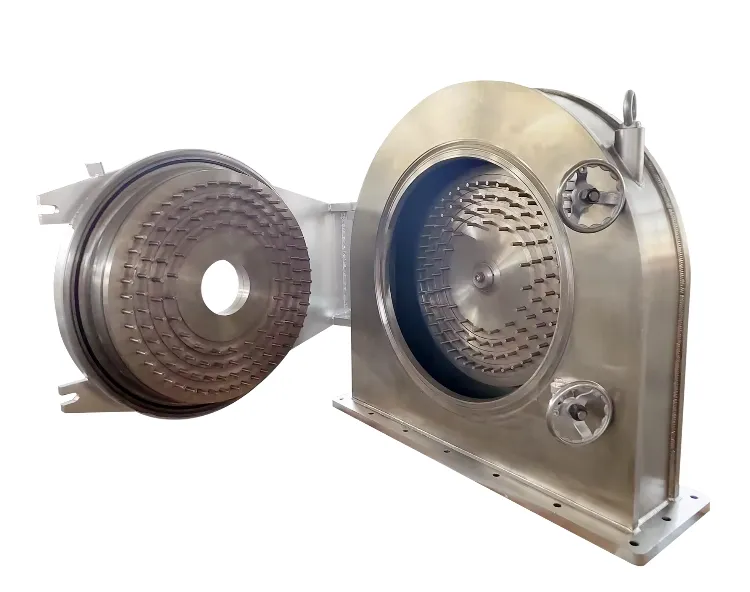

La clave para moler — La Molino de pasadores

Durante la producción de yeso α-hemihidratado, los trozos o aglomerados de yeso calcinado deben molerse y clasificarse para lograr la distribución granulométrica y la superficie específica deseadas. Los equipos de molienda tradicionales, como los molinos de martillos, de bolas y Raymond, suelen presentar un alto consumo de energía, una molienda excesiva y una baja uniformidad del tamaño de partícula.

Por el contrario, el molino de pasadores, con su exclusivo mecanismo de impacto y cizallamiento, se ha convertido en la opción ideal para la molienda fina y ultrafina de yeso α-hemihidratado.

Principio de funcionamiento

Un molino de pasadores consta de un rotor giratorio de alta velocidad y un estator estacionario, ambos equipados con pasadores distribuidos uniformemente. Cuando el material entra en la cámara de molienda, se somete a impactos, cizallamiento y fricción a alta velocidad entre los pasadores bajo fuerzas centrífugas y de flujo de aire, lo que resulta en una micronización eficiente.

Las partículas molidas pueden luego controlarse a través de un sistema de clasificación interno o externo (como un turboclasificador) para lograr una distribución precisa del tamaño de partícula, normalmente con valores D97 que oscilan entre 10 y 100 μm.

Ventajas técnicas del molino de pasadores

- Molienda a baja temperatura: El diseño de enfriamiento por aire evita eficazmente la transformación de cristales en materiales sensibles a la temperatura como el yeso.

- Finura ajustable: El tamaño de las partículas del producto se puede controlar con precisión regulando las velocidades del rotor y del clasificador.

- Excelente forma de partícula: Produce partículas casi esféricas, mejorando la dispersión y el rendimiento del moldeo.

- Limpio y libre de contaminación: Adecuado para industrias con altos requisitos de higiene como materiales de construcción, alimentos y productos farmacéuticos.

- Sistema estable y bajo consumo energético: En comparación con los molinos tradicionales, el consumo de energía se puede reducir entre 20% y 30%.

Flujo de proceso para la producción de polvo de yeso α-hemihidratado

- Pretratamiento de la materia prima: El yeso natural se tritura, se purifica y se tamiza.

- Calcinación en autoclave de alta presión: Conversión a yeso α-hemihidratado bajo presión de vapor de 1,3–1,8 MPa y 130–150 °C.

- Secado y enfriamiento: Estabiliza la estructura cristalina.

- Molienda con molino de pasadores: Reduce el tamaño de partícula a la finura deseada (D50: 5–20 μm).

- Sistema de clasificación del aire: Separa y recoge las fracciones de tamaño de partícula deseadas.

- Embalaje y almacenamiento de productos.

En este proceso, el sistema de circuito cerrado que combina el molino de pasadores y el clasificador mejora significativamente la finura y uniformidad del polvo, garantizando una calidad estable de los productos de yeso α-hemihidratado.

Campos de aplicación típicos

- Placas y moldes de yeso de alta resistencia:

El polvo de yeso α-hemihidrato fino y altamente activo mejora la densidad del producto y la resistencia a la flexión. - Materiales para suelos autonivelantes:

El polvo ultrafino mejora la fluidez y la capacidad de autocompactación al tiempo que reduce el tiempo de fraguado. - Fundición de precisión y moldes cerámicos:

La distribución uniforme de partículas garantiza superficies lisas y precisión dimensional de las piezas fundidas. - Productos de yeso médicos y artísticos:

El polvo de yeso α de alta pureza no es tóxico, es muy blanco y proporciona superficies lisas.

Conclusión

El yeso α-hemihidratado se caracteriza por su alta resistencia y bajo consumo de agua. Se ha convertido en el material fundamental para aplicaciones avanzadas de yeso. El molino de púas, como dispositivo de molienda ultrafina eficiente y preciso, proporciona un soporte técnico clave para el refinado y el control de calidad. Al combinarse, el yeso α-hemihidratado y el molino de púas garantizan una distribución óptima del tamaño de partícula y una calidad estable del polvo. Esto garantiza el rendimiento y la fiabilidad de productos finales como el yeso dental y materiales de construcción especiales. A medida que se expandan los campos de aplicación, el molino de púas seguirá desempeñando un papel crucial e irremplazable en la cadena de producción de yeso α-hemihidratado.