A ciência por trás do tamanho e da morfologia das partículas

Em meus mais de 20 anos de experiência com processamento de pó, Eu vi em primeira mão que é bruto químico A composição é apenas metade da batalha no desempenho da bateria. A estrutura física do material — especificamente, tamanho da partícula A forma e o formato determinam a densidade de energia final. Não nos limitamos a moer o material; projetamos a microestrutura para liberar todo o potencial do ânodo.

Encurtando os caminhos de difusão dos íons de lítio

A lógica aqui é simples, mas crucial: quanto maior a partícula, maior a distância que o íon de lítio precisa percorrer. Ao utilizar a moagem ultrafina do ânodo, reduzimos o tamanho das partículas para a faixa ideal de mícrons. Isso encurta significativamente o caminho de difusão do íon de lítio, diminuindo a resistência interna e permitindo taxas de carga e descarga mais rápidas sem superaquecer a célula.

Equilíbrio da Área de Superfície Específica (BET)

A moagem não se resume apenas a obter partículas o menor tamanho possível; trata-se de precisão. Se as partículas forem muito finas, a Área de Superfície Específica (BET) aumenta drasticamente, levando à formação excessiva da Interface Eletrólito Sólido (SEI) e à perda irreversível de capacidade.

- Aposta muito alta: Consome lítio em excesso durante o primeiro ciclo.

- Aposta muito baixa: Reduz os locais de reação, limitando a produção de energia.

- Nosso objetivo: Obtenha uma área de superfície controlada que equilibre reatividade e estabilidade.

Maximizando a densidade de compactação com partículas esféricas

O volume é precioso dentro de uma bateria. Partículas irregulares e quebradiças criam vazios e desperdício de espaço. Durante o processo de moagem, focamos em moldar as partículas em esferas para maximizar a densidade de compactação. Partículas esféricas se compactam firmemente, permitindo que carreguemos mais material ativo na pasta do eletrodo. Uma maior densidade de compactação se traduz diretamente em maior capacidade volumétrica, proporcionando à bateria maior tempo de funcionamento no mesmo formato.

Tecnologia de fresagem por jato em leito fluidizado

Ao buscar ânodos de alta capacidade, o método de moagem define a qualidade do produto final. Utilizamos o Leito Fluidizado. Fresamento a Jato Porque aborda os desafios críticos de pureza e integridade das partículas que a moagem mecânica tradicional simplesmente não consegue superar.

Mecanismo de colisão partícula-partícula

Em nossos sistemas, não moemos o material contra as paredes da máquina. Em vez disso, utilizamos ar comprimido de alta velocidade para acelerar as partículas, fazendo com que colidam umas com as outras. Esse mecanismo de colisão partícula-partícula oferece duas vantagens distintas:

- Desgaste reduzido: Como o material se tritura sozinho, o desgaste dos componentes do equipamento é mínimo.

- Morfologia preservada: Permite uma redução precisa do tamanho sem destruir a estrutura essencial do material do ânodo.

Controle de temperatura para materiais sensíveis ao calor

A geração de calor durante o processamento pode degradar compósitos anódicos complexos. Nosso processo de moagem a jato é inerentemente frio. À medida que o ar comprimido se expande pelos bicos, ele absorve calor, reduzindo efetivamente a temperatura dentro da câmara de moagem. Isso garante que materiais sensíveis ao calor sejam submetidos à moagem ultrafina do ânodo sem risco de oxidação ou danos térmicos.

Revestimentos cerâmicos para prevenir a contaminação por ferro

Para baterias de íon-lítio, a contaminação por metais é um fator crítico. Partículas de ferro podem causar curtos-circuitos internos e perda irreversível de capacidade. Para garantir a máxima pureza, projetamos nossos sistemas com Moagem com revestimento cerâmico (sem ferro) proteção.

- Proteção total: Todas as partes em contato com o material são revestidas com cerâmica de engenharia para isolá-lo do metal.

- Alta Pureza: Essa configuração garante que o pó final permaneça livre de impurezas metálicas, atendendo aos rigorosos padrões para materiais do eletrodo negativo da bateria.

Classificação integrada de ar para controle de PSD

Na EPIC Powder, sabemos que simplesmente moer o material não é suficiente para baterias de alto desempenho. O verdadeiro desafio reside em... Controle da Distribuição do Tamanho de Partículas (PSD). Se a distribuição for muito ampla, a capacidade do ânodo fica comprometida. É por isso que nossos sistemas priorizam a classificação integrada do ar para controlar rigorosamente a produção final de pó. Seja você utilizando um sistema de moagem padrão ou um sistema especializado. moinho de rolos, O classificador é o que diferencia o material de grau de bateria dos demais.

Eliminando o problema das “multas”

“As partículas finas (partículas ultrafinas) representam um grande problema na moagem ultrafina de ânodos. Elas criam uma área superficial específica excessiva, o que leva a reações secundárias indesejadas e à formação instável da interface de eletrólito sólido (SEI).

- Separação de precisão: Nosso Sistema de classificação de ar (como a série MJW) corta efetivamente a cauda fina da distribuição.

- Redução do desperdício: Ao remover essas partículas submicrométricas, reduzimos a perda irreversível de capacidade no primeiro ciclo.

- Eficiência: Garantimos que apenas as partículas dentro da faixa de tamanho ideal cheguem ao coletor do produto final.

Obtendo uma curva PSD acentuada

Para maximizar a densidade de energia, é necessário uma curva PSD "íngreme". Isso significa que a diferença entre os parâmetros de partícula D50 e D97 é minimizada, resultando em um tamanho de partícula uniforme.

- Alta densidade de compactação: Uma distribuição estreita permite que as partículas se compactem mais, aumentando a densidade de energia volumétrica do ânodo.

- Consistência: Nossos classificadores utilizam projetos de rotores avançados para manter essa curva acentuada de forma consistente durante as operações de produção contínua.

Garantir um revestimento uniforme do eletrodo

O benefício subsequente do controle rigoroso da distribuição do tamanho de partículas (PSD) é evidente durante o processo de fabricação dos eletrodos. Um pó uniforme cria uma pasta lisa e sem defeitos.

- Melhor Reologia: Partículas uniformes dispersam-se melhor em aglutinantes, evitando a aglomeração.

- Mais suave Revestimento: Isso resulta em uniformidade do revestimento do eletrodo, garantindo que os íons de lítio tenham acesso consistente ao material ativo em toda a superfície da folha.

- Garantia da Qualidade: Ao controlar o tamanho na fase de moagem, evitamos problemas como quebra da folha ou secagem irregular posteriormente na linha de produção.

Técnicas de Modificação de Superfície e Esferoidização

Na EPIC Powder, entendemos que alcançar alta densidade de energia vai além da simples redução de tamanho. Para otimizar verdadeiramente o desempenho da bateria, precisamos controlar a morfologia das partículas e a química da superfície. Nossas soluções avançadas de processamento focam na esferoidização do ânodo, transformando partículas irregulares e escamosas em formatos esféricos e suaves. Essa mudança morfológica aumenta significativamente a densidade aparente, permitindo que mais material ativo seja compactado no volume da célula da bateria.

Mecanofusão para arredondamento de bordas de grafite

As arestas vivas das partículas de grafite podem danificar o separador e levar à formação irregular da interface de eletrólito sólido (SEI). Utilizamos técnicas de modificação mecanoquímica de superfície para arredondar mecanicamente essas arestas sem danificar a estrutura interna da partícula. Aplicando forças precisas de cisalhamento e compressão, nosso equipamento suaviza a superfície da partícula. Esse processo reduz a área superficial específica (BET) a níveis ótimos, minimizando a perda irreversível de capacidade durante o primeiro ciclo e garantindo maior estabilidade da SEI.

Retificação e revestimento de carbono em uma única etapa

A eficiência é fundamental na fabricação moderna de baterias. Projetamos sistemas integrados que combinam redução de tamanho com tratamento de superfície. Nossa equipe especializada utiliza tecnologia de ponta para criar soluções eficazes. máquina de modificação de revestimento em pó Permite processos simultâneos de retificação e revestimento. Essa integração garante a aplicação de uma camada uniforme de carbono ao material do ânodo imediatamente após a criação de novas superfícies. Essa abordagem "em uma única etapa" previne a oxidação das superfícies recém-expostas e garante uma rede condutora homogênea, o que é vital para um alto desempenho em altas taxas de carga/descarga.

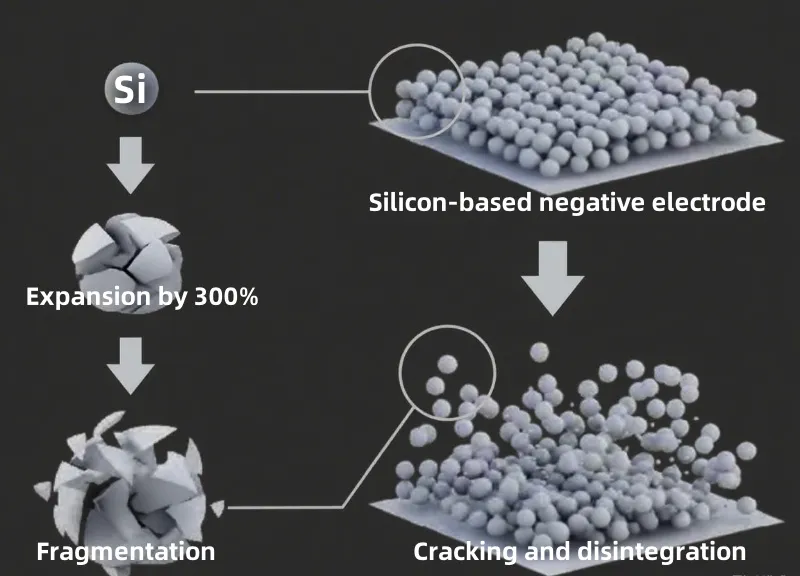

Amortecimento da expansão volumétrica em ânodos de silício

Para materiais de ânodo de silício-carbono (Si/C) de próxima geração, o controle da expansão volumétrica é o maior desafio. O silício se expande significativamente durante a litiação, levando a rachaduras e pulverização. Nossas tecnologias de modificação de superfície permitem a criação de uma camada protetora robusta ao redor das partículas de silício. Ao aplicar um revestimento de carbono preciso ou uma estrutura composta durante a fase de moagem, ajudamos a conter essa expansão. Essa camada protetora mantém o contato elétrico e a integridade mecânica, prolongando a vida útil dos ânodos de silício de alta capacidade.

Estudo de caso: Otimizando ânodos de silício-carbono (Si/C)

O processamento de materiais de ânodo de silício-carbono (Si/C) apresenta desafios únicos devido à tendência do material de expandir e rachar durante os ciclos de carga e descarga da bateria. Desenvolvemos linhas de processamento especializadas que abordam esses problemas de estabilidade de forma direta, garantindo que a alta capacidade teórica se traduza em desempenho no mundo real.

Solução para o problema de fissuras no silício

A chave para estabilizar ânodos de silício reside na minimização do estresse mecânico durante a fase de moagem. Ao contrário dos moinhos mecânicos convencionais, que podem induzir microfissuras, nossos moinhos de jato de leito fluidizado utilizam a colisão partícula-partícula. Esse método mantém a integridade estrutural do material compósito, ao mesmo tempo que atinge a finura necessária. Recentemente, nosso A tecnologia de moinho de jato possibilitou a produção de materiais de ânodo de carbono duro ultrafinos. Para atender aos rigorosos padrões dos principais fabricantes de baterias na Coreia, demonstramos nossa capacidade de lidar com estruturas de ânodo sensíveis sem degradação.

Redução do tamanho para nanoescala até níveis submicrométricos (<150nm)

Para acomodar a expansão de volume, a redução do tamanho das partículas é imprescindível. Nossos equipamentos são projetados para reduzir o tamanho das partículas a níveis submicrométricos (<150 nm), um limite crítico para ânodos de próxima geração.

- Controle de precisão: Obtemos uma distribuição de tamanho de partículas (PSD) acentuada que elimina partículas de tamanho excessivo, as quais contribuem para o inchaço do eletrodo.

- Uniformidade: A granulometria consistente em escala submicrométrica garante melhor dispersão dentro da matriz condutora.

Proteção com gás inerte para segurança

O pó de silício é altamente reativo e representa um risco significativo de explosão. Priorizamos a segurança integrando sistemas de moagem com proteção por gás inerte em nossas linhas de moagem ultrafina de ânodos. Ao circular nitrogênio em um sistema de circuito fechado, mantemos os níveis de oxigênio rigorosamente controlados. Isso evita a oxidação das superfícies de silício recém-preparadas e elimina os riscos de explosão, garantindo um ambiente de produção seguro e estável para materiais de alta densidade energética.

Perguntas frequentes: Moagem ultrafina de ânodos e capacidade

O método de moagem afeta a eficiência coulombiana inicial?

Com certeza. O método escolhido para a moagem ultrafina do ânodo impacta diretamente a área superficial das partículas. Se um processo de moagem produz muitas partículas finas (partículas extremamente pequenas), ele aumenta drasticamente a área superficial específica (BET).

Durante o primeiro ciclo de carga da bateria, uma grande área de superfície consome mais íons de lítio para formar a camada de eletrólito sólido (SEI). Isso resulta em perda irreversível de capacidade, o que significa que você perde capacidade antes mesmo da bateria sair da fábrica. Ao otimizar a distribuição do tamanho das partículas (PSD) e remover partículas finas, ajudamos você a manter uma alta eficiência.

Moagem a jato versus moagem mecânica para ânodos

A escolha entre essas duas opções depende dos seus objetivos de pureza e densidade.

- Moinho a jato de leito fluidizado: Esta é a melhor opção para materiais de alta pureza, como o ânodo de silício-carbono (Si/C). Como utiliza a colisão partícula-partícula em vez de meios de moagem, o risco de contaminação por ferro é zero. Produz uma curva de distribuição de tamanho de partículas (PSD) acentuada, ideal para aplicações de alta tecnologia.

- Fresagem mecânica: Este método costuma ser mais eficiente em termos energéticos do que o processamento padrão de grafite. No entanto, requer resfriamento cuidadoso e revestimentos cerâmicos para evitar contaminação.

Para aplicações avançadas que exigem modelagem precisa, frequentemente integramos modificação da superfície do pó Tecnologias para esferoidizar as partículas após a moagem, melhorando a densidade aparente.

Como lidar com poeira de silício explosiva durante o processamento?

O processamento de ânodos à base de silício apresenta um desafio significativo em termos de segurança, pois a poeira é altamente explosiva. Não é possível processá-la em um moinho convencional a céu aberto.

Utilizamos sistemas de moagem com proteção de gás inerte para esses materiais. Isso envolve um projeto de circuito fechado preenchido com nitrogênio ou argônio para manter os níveis de oxigênio extremamente baixos. Isso evita tanto a oxidação do material quanto explosões de poeira. Se você estiver planejando uma instalação para materiais de baterias de última geração, pode consultar nosso [link para o produto/serviço/etc.]. casos de projetos bem-sucedidos Para ver como projetamos esses sistemas à prova de explosão para clientes globais.

Obrigado pela leitura. Espero que meu artigo tenha ajudado. Deixe um comentário abaixo. Você também pode entrar em contato com o suporte online da Zelda para quaisquer outras dúvidas.

— Publicado por Emily Chen