Quais são o estado atual da pesquisa e os desafios dos materiais catódicos de azul da Prússia para baterias de íon-sódio?

Nos últimos anos, as baterias de íon-lítio têm sido amplamente utilizadas nos mercados de energia e armazenamento de energia. Como resultado, os recursos de lítio tornaram-se cada vez mais escassos. As baterias de íon-sódio operam com um princípio semelhante e apresentam desempenho comparável ao das baterias de íon-lítio. No entanto, em comparação com as baterias de íon-lítio, as baterias de íon-sódio têm diversas vantagens claras: elas também oferecem bom desempenho de potência, […]

Quais são as 20 tecnologias e sistemas de processamento intensivo para bentonita?

O processamento da bentonita refere-se às tecnologias abrangentes de aprimoramento, purificação, modificação e aplicação de alto valor agregado aplicadas à bentonita, uma rocha argilosa hidratada composta principalmente de montmorilonita. A bentonita possui excelente capacidade de expansão, adsorção, capacidade de troca catiônica, atividade catalítica, desempenho de ligação, estabilidade de suspensão e plasticidade. É amplamente conhecida como "argila multiuso". A bentonita natural frequentemente contém minerais de ganga, como […]

Como a tecnologia de moagem ultrafina permite que o talco, o "mineral mais macio", seja utilizado em setores de fabricação de alta tecnologia?

O talco, um mineral muitas vezes negligenciado, ocupa o último lugar na escala de dureza de Mohs, mas sua "maciez" lhe confere uma resistência "extrema". Sendo o mineral mais macio conhecido, o talco desempenha papéis importantes não apenas no dia a dia, mas também se destaca em diversos setores. No entanto, seu verdadeiro potencial é frequentemente revelado por meio do processo de produção de talco ultrafino moído, [...]

Quais são as causas da baixa atividade durante a moagem de pó de escória e suas soluções?

1. Causas da Baixa Atividade do Pó de Escória Muitos fatores contribuem para a baixa atividade do pó de escória. Uma alta proporção de fases cristalinas e uma estrutura cristalina completa são fatores primordiais. Além disso, um alto teor de óxidos ácidos, como o SiO2, e um baixo teor de óxidos básicos, como o CaO, reduzem ainda mais a atividade. Ao analisar […]

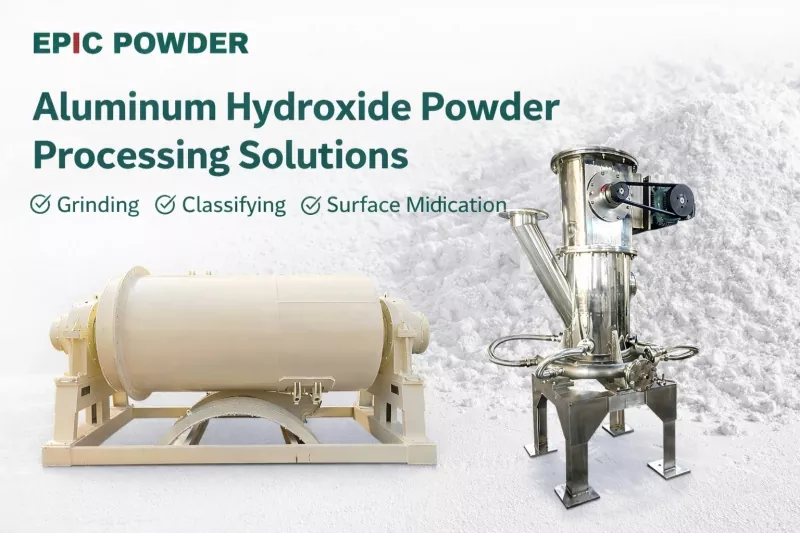

Quais são os processos de preparação do pó ultrafino de hidróxido de alumínio e seus mecanismos de modificação de superfície?

O hidróxido de alumínio (ATH) possui múltiplas funções, incluindo retardamento de chama, supressão de fumaça e preenchimento. Não produz poluição secundária e pode gerar efeitos sinérgicos de retardamento de chama com diversas substâncias. Portanto, é amplamente utilizado como aditivo retardante de chama em materiais compósitos e tornou-se o retardante de chama inorgânico ecologicamente correto mais consumido. Quando o hidróxido de alumínio […]

Por que a moagem ultrafina está se tornando essencial para as aplicações modernas da bentonita?

A bentonita é amplamente aclamada como a “argila universal”, sendo seu principal componente mineral a montmorilonita. Este silicato em camadas, forjado a partir de cinzas vulcânicas ao longo de milhões de anos, abrange dois mundos completamente diferentes: desde areia higiênica para gatos ($10 por saco) até aditivos químicos de alta precisão. Essa versatilidade não é apenas resultado de sua química natural, mas sim uma obra-prima de […]

A pulverização ultrafina de carbonato de sódio realmente resolve o problema do baixo desempenho em altas taxas de descarga das baterias de íon-sódio?

As baterias de íon-sódio (SIBs) têm atraído considerável atenção nos últimos anos devido à abundância de recursos de sódio, baixo custo e vantagens em desempenho em baixas temperaturas e segurança. No entanto, em comparação com as baterias de íon-lítio, que já estão consolidadas, as SIBs ainda enfrentam uma desvantagem significativa: a baixa capacidade de taxa de descarga. A capacidade de taxa de descarga refere-se à habilidade da bateria de manter sua capacidade e permitir cargas/descargas rápidas em altas temperaturas.

Como obter controle morfológico de partículas em pó?

O controle da morfologia de partículas de pó é uma das tecnologias essenciais na preparação de materiais avançados. Ele determina diretamente a densidade de empacotamento, a fluidez, a atividade de sinterização e a microestrutura e o desempenho finais de produtos cerâmicos. O objetivo do controle da morfologia é obter formatos de partículas específicos, uniformes e reproduzíveis. As seções a seguir detalham as principais técnicas de controle da morfologia.

Por que usar um moinho de jato de ar para moer Centella Asiatica? Vantagens em comparação com os métodos tradicionais de moagem.

A Centella asiatica (também conhecida como Gotu Kola) é uma importante planta medicinal e comestível. Seus principais compostos ativos — principalmente triterpenoides (como asiaticosídeo, madecassosídeo, ácido asiático e ácido madecássico), juntamente com flavonoides e polifenóis — são muito procurados nas indústrias farmacêutica, nutracêutica e cosmética modernas. Essas aplicações impõem requisitos rigorosos quanto à finura, uniformidade, […]