Dolomit ialah batuan karbonat yang kaya dengan kalsium dan magnesium. Ia terutamanya terdiri daripada dolomit dengan jumlah kecil kalsit, mineral tanah liat, batu api, dan magnesit. Kadangkala, ia mengandungi gipsum, anhidrit, dan barit. Ia adalah salah satu kelebihan China mineral bukan logam sumber. Ia mempunyai rizab yang besar, berkualiti tinggi, dan pengedaran yang luas.

Penggunaan Dolomit

Industri Refraktori Metalurgi

Ia digunakan sebagai agen pembuatan sanga magnesium dalam pembuatan keluli untuk menggabungkan silikon cair, aluminium, sulfur, fosforus dan unsur-unsur berkaitan yang tidak perlu atau berbahaya untuk membentuk sanga yang mudah diasingkan daripada keluli cair. Pengekstrakan logam magnesium; bahan tahan api pembuatan keluli, dsb.

Industri kimia

Ia digunakan untuk menghasilkan magnesium sulfat, magnesium oksida, magnesium karbonat ringan (mendakan magnesium karbonat), pasir magnesia dan pengisi getah/plastik.

Industri Pembinaan

Ia digunakan untuk menghasilkan simen magnesium sulfat, simen klorida-magnesium berprestasi tinggi,

batu bata silikat kapur terbakar, dan untuk merawat keretakan dalam gipsum dan produk kayu.

Pertanian dan Perhutanan

Perapi tanah berasid atau peneutral, pencegahan wabak, racun perosak, dsb.

Industri Kaca

Selain pasir silika dan abu soda, batu kapur dan dolomit adalah komponen ketiga terbesar bahan mentah kaca. Mereka bertindak sebagai fluks dan boleh mengurangkan penuaan kaca, meningkatkan keplastikan kaca berwarna, dan meningkatkan kekuatan kaca.

Industri Seramik

Dolomit digunakan dalam kosong seramik dan glazes, dan MgO dan CaCO3 diperkenalkan untuk menggantikan talc dan kalsit.

Perlindungan Alam Sekitar

Bahan penapis dolomit digunakan dalam rawatan air. Mereka sesuai untuk meneutralkan air minuman, air industri, dan air kolam. Mereka juga membantu menghilangkan besi, mangan, dan silikat.

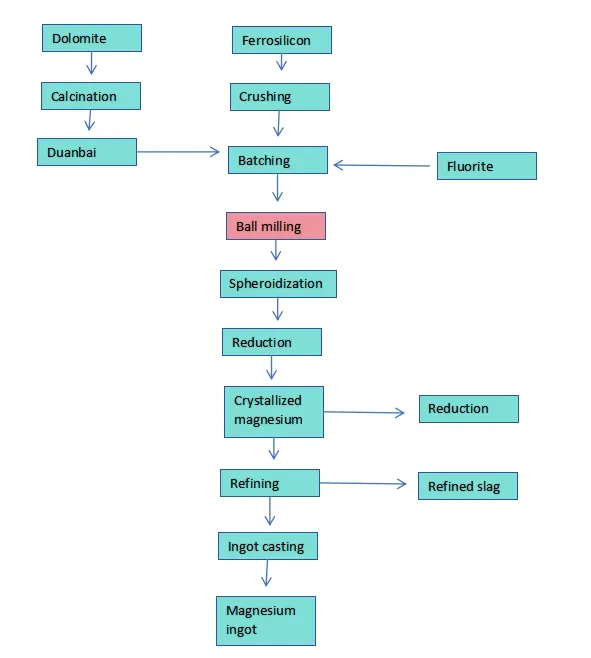

Peleburan logam magnesium

Dolomit dengan a saiz Zarah 30–120mm ialah bahan mentah yang penting untuk menghasilkan magnesium logam. Kaedah peleburannya terbahagi kepada dua jenis: elektrolisis dan pengurangan silikotermik. Pada masa ini, kaedah pengurangan silikotermik biasanya digunakan di dalam negara. Magnesium yang dihasilkan melalui kaedah ini menyumbang 20% daripada jumlah keluaran magnesium.

Proses Pidgeon untuk peleburan logam magnesium

Penyediaan Magnesium Karbonat

Magnesium Karbonat ringan

Magnesium karbonat ringan ialah pengisi tak organik premium, agen pengukuh, dan kalis api yang berkesan dalam industri getah dan plastik. Ia digunakan sebagai pengisi dalam dakwat, pigmen, ubat gigi dan kosmetik mewah. Ia juga berfungsi sebagai bahan mentah untuk seramik gred tinggi, kaca, dan salutan kalis api.

Terdapat tiga kaedah pengeluaran utama kerana penggunaan bahan mentah yang berbeza: pengkarbonan dolomit, pengkarbonan air garam, dan penukaran ammonium sulfat. Pada masa ini, kaedah pengkarbonan dolomit digunakan secara meluas di China untuk menghasilkan magnesium karbonat ringan.

Magnesium Karbonat Sfera Ringan

Magnesium karbonat sfera ringan mempunyai isian, keterserakan dan kebolehlilir yang sangat baik.

Ia meningkatkan kekuatan tegangan dan rintangan haus getah, menjadikannya pengisi dan agen pengukuhan yang sangat baik untuk produk getah dan plastik. Ia juga digunakan sebagai pengisi dalam industri seperti salutan cat, ubat gigi, kosmetik, dan farmaseutikal.

Magnesium Karbonat Lutsinar Cahaya

Magnesium karbonat telus cahaya dicirikan oleh zarah halus dengan saiz zarah seragam. Ia adalah bukan organik yang ditapis kimia produk. Selain digunakan sebagai bahan tambahan dalam cat, salutan, dakwat, ubat gigi, farmaseutikal dan kosmetik, ia digunakan terutamanya sebagai pengisi dan agen penguat dalam produk getah telus atau berwarna terang.

Penyediaan Magnesium Oksida Ringan

Magnesium oksida ringan boleh digunakan sebagai pengisi dan agen penguat dalam kertas, salutan, plastik, dan getah. Ia adalah bahan mentah untuk cawan pijar dan seramik tahan haba mewah. Ia juga digunakan sebagai agen penggilap, plasticizer untuk gentian kaca, permukaan salutan untuk kepingan keluli silikon, dan sebagai antacid dan julap ringan dalam farmaseutikal.

Kesimpulan

Kesimpulannya, dolomit adalah mineral serba boleh dan berharga dengan pelbagai aplikasi merentasi pelbagai industri. Daripada pembuatan keluli dan rawatan air kepada pengeluaran produk magnesium berkualiti tinggi dan seramik termaju, sifat uniknya menjadikannya amat diperlukan. Sebagai sumber semula jadi dan bahan perindustrian, dolomit terus memainkan peranan penting dalam pembangunan banyak sektor, menyokong inovasi berterusan dan kemampanan industri moden. Memahami komposisi, kaedah pemprosesan dan kegunaannya adalah penting untuk memanfaatkan potensi penuhnya dalam pasaran hari ini.

Bedak Epik

Serbuk Epik, 20+ tahun pengalaman kerja dalam industri serbuk ultrahalus. Secara aktif menggalakkan pembangunan serbuk ultra-halus masa hadapan, memfokuskan pada proses penghancuran, pengisaran, pengelasan dan pengubahsuaian serbuk ultra-halus. Hubungi kami untuk perundingan percuma dan penyelesaian tersuai! Pasukan pakar kami berdedikasi untuk menyediakan produk dan perkhidmatan berkualiti tinggi untuk memaksimumkan nilai pemprosesan serbuk anda. Serbuk Epik—Pakar Pemprosesan Serbuk Dipercayai Anda!