Particle classification refers to separating particles of the same material according to differences in physical properties such as kích thước hạt, shape, or density. In most cases, classification specifically means separating particles by size. The two core technical elements of classification are dispersion and separation.

Dispersion requires that the material entering the classification chamber be as fully dispersed as possible. Separation means that qualified fine particles must be promptly removed from the classification zone.

With the rapid development and expanding applications of ultrafine powders across multiple industries, classification technologies have also advanced significantly. Among various solutions, the turbo air classifier has become the mainstream choice. This is due to its high efficiency, high accuracy, and wide operational flexibility.

Working Principle of Turbo Air Classifier

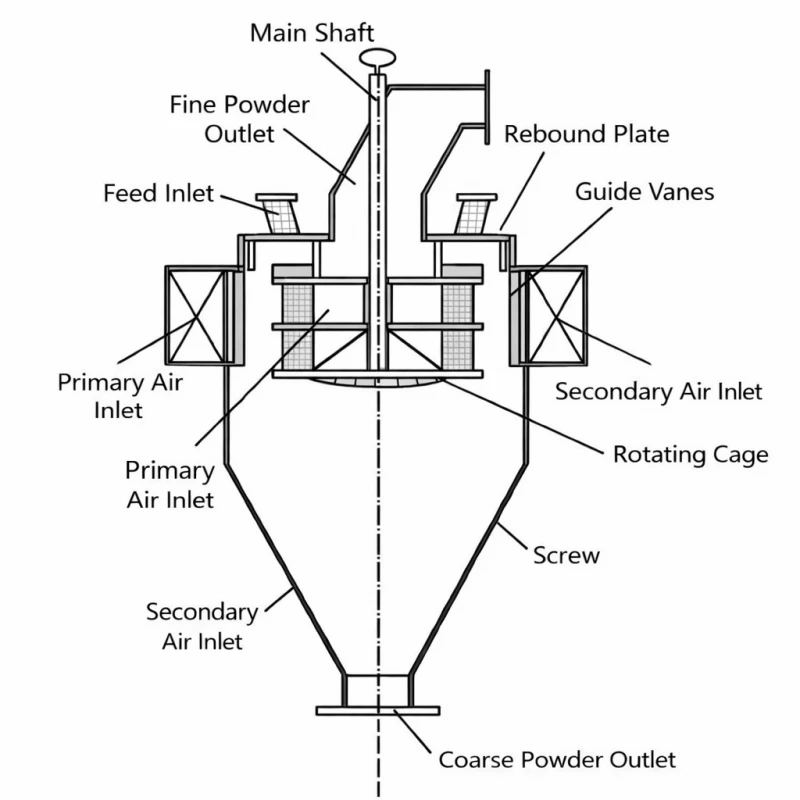

Material to be classified falls from the feed inlet onto the distribution plate.

It rotates together with the plate. The material is then thrown outward along the tangential direction. After striking the impact plate, particles enter the region between the outer edge of the rotor cage and the guide vanes. Primary air and secondary air enter the classifier tangentially. They pass through the guide vanes and form a swirling airflow. The airflow rotates in the same direction as the rotor cage.

Inside the annular classification zone, particles are mainly subjected to three forces:

- Centrifugal force toward the classifier wall

- Radial fluid drag force

- Pressure gradient force toward the center

Fine particles experience relatively small centrifugal force, so the resultant force directs them toward the center of the rotor cage. They are carried by airflow into the rotor and discharged through the fine powder outlet along the axial direction. Coarse particles experience much stronger centrifugal force. Their resultant force points toward the classifier wall. After colliding with the wall, they move downward. They are discharged through the coarse powder outlet.

Schematic diagram of turbo máy phân loại không khí

Advantages of Turbine Air Classifier

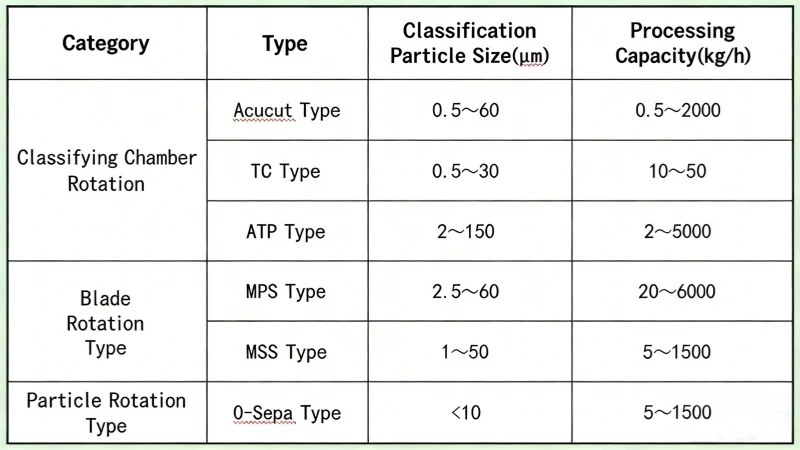

According to rotor cage structure, turbo air classifiers can generally be divided into three main categories with six structural forms. Although structural differences exist, they share several common advantages:

Turbine air classifiers are classified according to the form of the rotating drum

- Higher Processing Capacity

Compared with earlier generations of air classifiers, turbo air classifier offer larger throughput. Their special rotor cage design ensures more uniform gas flow distribution, better gas–solid mixing, and faster completion of classification in the classification zone. - Higher Efficiency and Lower Energy Consumption in Closed-Circuit Grinding Systems

When combined with grinding mills, turbo air classifiers significantly reduce over-grinding and secondary milling, thereby saving energy, lowering costs, and improving overall economic efficiency. - Wide Adjustable Particle Size Range and Easy Operation

By adjusting rotor speed and air volume, the sensitivity of the flow field to particle size can be controlled, enabling flexible regulation of the cut size and product particle size distribution. - Easy Maintenance and Low Spare-Part Cost

With a relatively simple structure and mainly complex rotor cage components, turbo air classifiers feature good part interchangeability and low maintenance cost.

Challenges of Turbo Air Classifiers

Despite their advantages, several challenges become apparent as turbo air classifiers are applied to a wider range of materials:

- Particle Agglomeration

After ultrafine grinding, powders exhibit increased specific surface area and surface energy, resulting in higher surface activity. Interparticle attraction increases, and moisture or impurities can further promote agglomeration. This effect is particularly severe for particles smaller than 1 μm, making classification more difficult. Therefore, effective dispersion into a single-particle state is essential for improving flowability and classification performance. - Non-Uniform Airflow Distribution

The volute structure, vane geometry, and duct installation angles may cause uneven airflow distribution in the classification chamber. This can intensify turbulence or create local vortices, which significantly reduces classification accuracy and efficiency. - Limited Precision for Submicron Particles

Existing classifiers struggle to maintain high precision and efficiency for particles below 1 μm, making it difficult to meet the stringent demands of modern high-tech industries for “fine and narrow” particle size distributions. - Trade-Off Between Efficiency and Accuracy

Classification capacity and classification precision constrain each other. Increasing throughput or particle concentration often reduces precision. Conversely, maintaining high precision typically leads to lower efficiency. Balancing these two factors remains a major technical challenge.

As a result, improving the performance of ultrafine powder classifiers and overcoming these technical limitations has become a key focus for researchers and equipment manufacturers worldwide.

Cảm ơn bạn đã đọc. Tôi hy vọng bài viết của tôi hữu ích. Vui lòng để lại bình luận bên dưới. Bạn cũng có thể liên hệ với bộ phận chăm sóc khách hàng trực tuyến của Zelda nếu có bất kỳ thắc mắc nào khác.

— Đăng bởi Emily Chen