O polipropileno (PP) é um polímero termoplástico amplamente utilizado, conhecido por sua facilidade de processamento e excelentes propriedades. Isso o torna essencial em indústrias como embalagens, eletrodomésticos e peças automotivas. Apesar de seu amplo uso, o PP apresenta certas limitações, incluindo alta retração térmica, baixo desempenho em baixas temperaturas e resistência inadequada ao impacto. Essas deficiências impulsionaram o desenvolvimento de estratégias para aprimorar as propriedades do PP. Um método eficaz é a incorporação de diversos mineral pós para modificação de polipropileno, melhorando seu desempenho geral. Ao adicionar compostos inorgânicos pós minerais, como carbonato de cálcio, talco e mica, a estabilidade térmica do PP pode ser melhorada. Isso também melhora sua resistência ao impacto e seu desempenho geral. Como resultado, a aplicabilidade do PP se amplia em diversos setores e ambientes desafiadores.

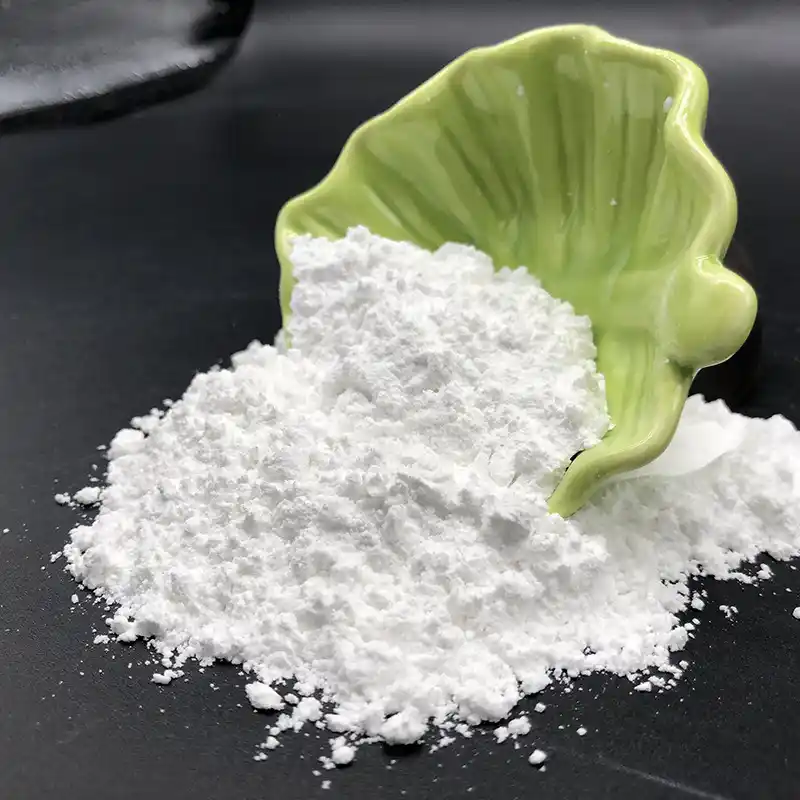

Carbonato de cálcio

Carbonato de cálcio, com seus recursos abundantes, variedade, não toxicidade e facilidade de processamento, é amplamente utilizado em cargas de resina. Sua aplicação é particularmente significativa em cargas de polipropileno (PP). O carbonato de cálcio é dividido principalmente em três tipos: nano, pesado e leve. Esses diferentes tipos de pós de carbonato de cálcio apresentam impactos de desempenho únicos em cargas modificadas com polipropileno, com base em suas propriedades físicas e químico propriedades.

Talco

Talco, um mineral natural rico em silicato de magnésio, possui uma estrutura em camadas única, bom isolamento e estabilidade. É amplamente utilizado em aplicações de polipropileno (PP). O talco reduz significativamente a taxa de retração dos materiais de PP. Também melhora o módulo de tração em certa medida, melhorando as propriedades mecânicas e a estabilidade.

Mica

A mica, com suas propriedades físicas e químicas únicas, desempenha um papel importante em materiais isolantes, plásticos, borracha, papel e tintas. Possui uma estrutura especial de grande proporção, aprimorando produtos plásticos. Ela melhora as propriedades físicas de peças mecânicas, componentes de veículos, produtos de madeira plástica, carcaças de eletrodomésticos e embalagens. A mica também aprimora as propriedades de filmes, fibras e cordas.

Dióxido de silício

O pó de sílica, um material inorgânico amplamente utilizado, é apreciado por sua alta pureza, formato uniforme e diversos métodos de preparação. Em particular, a nanossílica possui uma estrutura de rede tridimensional única e grande área superficial específica. Ela pode melhorar significativamente o desempenho geral de materiais compósitos, especialmente quando aplicada a produtos poliméricos.

Caulino

O caulim é composto principalmente de minerais de argila caulinite. É um pó formado durante o intemperismo de feldspato, piroxênios e outros minerais de aluminossilicato. Este pó normalmente tem uma aparência opaca. Quando puro, tem uma textura branca e fina. Apresenta plasticidade, adesividade e expansão volumétrica. O caulim pode melhorar a resistência à tração e o módulo de elasticidade de materiais termoplásticos, aumentando a rigidez e a resistência de produtos plásticos. Quando adicionado ao polipropileno, também atua como um agente nucleante. Após a calcinação, o caulim melhora significativamente a resistência do isolamento elétrico dos plásticos e pode ser usado em fios, cabos e produtos de isolamento de alta tensão. A capacidade do caulim de bloquear a radiação infravermelha é notável e tem sido aplicada em equipamentos militares. Em filmes, pode melhorar as propriedades de isolamento térmico.

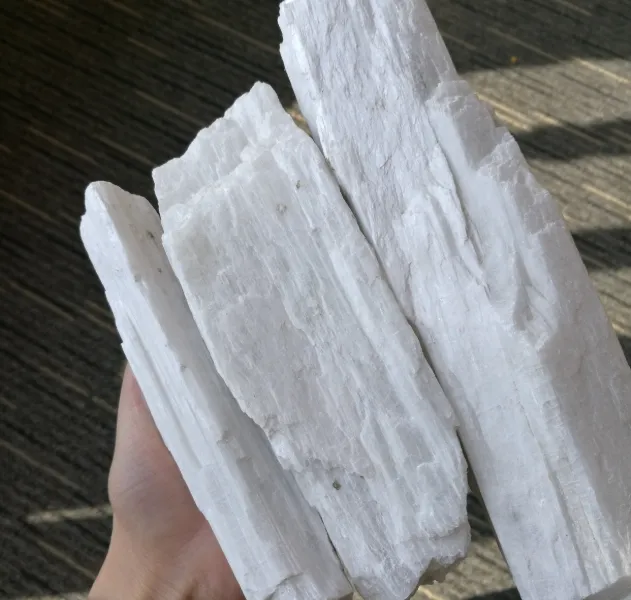

Wollastonita

A wollastonita pode ser amplamente utilizada em resinas como PET, PA, PE, PP e ABS. Muitas de suas propriedades são semelhantes às de pós inorgânicos como talco e mica. Como um novo modificador inorgânico para plásticos, a técnica de processamento deve se concentrar em manter a grande razão de aspecto de sua estrutura fibrosa. A modificação por ativação de superfície com agentes de acoplamento de silano é usada para melhorar ou garantir a compatibilidade entre diferentes interfaces de materiais. A wollastonita pode aumentar a temperatura de distorção térmica das resinas. Ela melhora a resistência e a redução do módulo em resinas sensíveis à umidade. Isso ocorre quando as resinas são expostas a ambientes úmidos. As propriedades físicas também apresentam melhorias significativas, dependendo da resina utilizada.

Sulfato de Bário

O sulfato de bário (BaSO4) pode ser classificado em dois tipos: sulfato de bário natural, também conhecido como pó de barita, e sulfato de bário sintético. O sulfato de bário sintético possui uma área superficial específica que varia de 22.000 a 140.000 cm²/g. Como carga plástica, alisa a superfície dos produtos e confere bom brilho. O sulfato de bário também oferece excelentes propriedades, como estabilidade química, resistência a riscos, resistência ao calor, índice de refração e facilidade de dispersão. Proporciona isolamento acústico e térmico superiores e alto brilho em comparação com muitos outros pós inorgânicos. É amplamente utilizado em aplicações como carcaças de eletrodomésticos, masterbatches, filmes, tubos e perfis. No entanto, a densidade do sulfato de bário é um fator importante que influencia seu desempenho na aplicação.

Conclusão

Existe uma grande variedade de pós inorgânicos, e a aplicação desses pós em tecnologias de modificação de PP é relativamente madura. Considerando a diversidade de aplicações subsequentes, os requisitos de desempenho para PP inevitavelmente variam. Nesse contexto, a ampla gama de pós minerais para modificação de polipropileno oferece mais opções, permitindo modificações direcionadas de enchimento para atender a necessidades específicas de desempenho. Ao selecionar os pós minerais apropriados, as propriedades mecânicas do PP podem ser adaptadas para diversos setores. As propriedades térmicas e químicas do PP também podem ser ajustadas para atender a necessidades específicas. Isso melhora a versatilidade e o desempenho geral do material em diferentes aplicações.

Pó épico

Epic Powder, com mais de 20 anos de experiência na indústria de pós ultrafinos. Promovemos ativamente o desenvolvimento futuro de pós ultrafinos, com foco nos processos de britagem, moagem, classificação e modificação de pós ultrafinos. Entre em contato conosco para uma consulta gratuita e soluções personalizadas! Nossa equipe de especialistas se dedica a fornecer produtos e serviços de alta qualidade para maximizar o valor do seu processamento de pós. Epic Powder — Seu especialista confiável em processamento de pós!