Gambaran Keseluruhan Kes

| item | Penerangan |

|---|---|

| Pelanggan / Lokasi | Pengeluar serbuk logam berprestasi tinggi yang terkenal di Thailand |

| bahan | Sejenis serbuk logam aloi berprestasi tinggi |

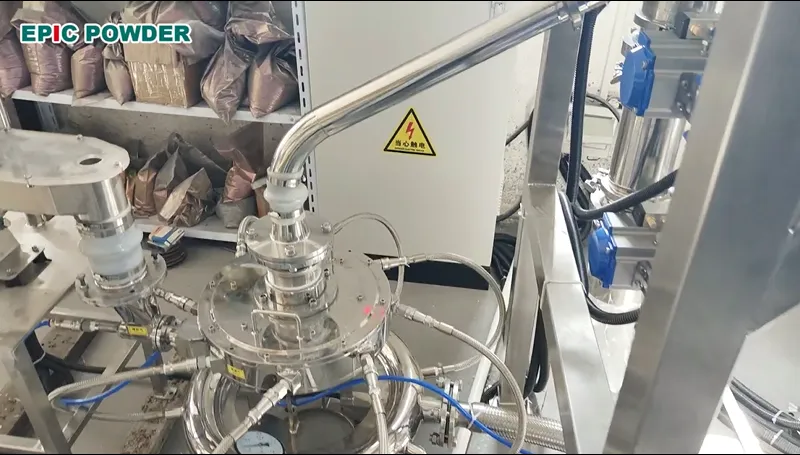

| Jenis Peralatan | Kilang Jet Lingkaran |

| Cabaran Teras | Mencapai klasifikasi serbuk logam ultrahalus dengan sangat sempit saiz Zarah pengedaran dalam Pemprosesan Serbuk etal untuk memenuhi keperluan kualiti yang ketat bagi pembuatan termaju (seperti pembuatan aditif/pencetakan 3D atau pengacuan suntikan logam). |

| Sasaran | Saiz zarah produk akhir D99.9 ≤ 8 μm |

Cabaran & Keperluan

Dengan pertumbuhan pesat pembuatan termaju global—terutama penggunaan meluas pembuatan bahan tambahan (pencetakan 3D)—keperluan untuk ketulenan serbuk, sfera dan pengedaran saiz zarah telah menjadi lebih menuntut berbanding sebelum ini. Sebagai pembekal serbuk logam berprestasi tinggi terkemuka di rantau ini, pelanggan Thailand menghadapi beberapa cabaran utama:

- Keperluan Kehalusan Yang Sangat Tinggi

Indeks saiz zarah sasaran ialah D99 ≤ 8 μm atau lebih halus. Ini bermakna 99.9% zarah mestilah di bawah 8 μm, memerlukan prestasi pengelasan yang sangat tepat. - Keperluan Gabungan untuk Deaglomerasi dan Klasifikasi Berkesan

Serbuk logam cenderung menggumpal dengan mudah. Input tenaga yang kuat diperlukan untuk deaglomerasi yang berkesan, dan pengelasan yang tepat mesti diikuti untuk mengelakkan zarah bersaiz besar daripada memasuki produk akhir. - Mengekalkan Sifat Bahan

Proses pengisaran dan pengelasan mesti meminimumkan kesan ke atas morfologi serbuk dan kimia ketulenan, memelihara ciri-ciri prestasi tinggi yang wujud.

Penyelesaian daripada Bedak Epik

Untuk menangani cabaran ini, Epic Powder mengesyorkan dan melaksanakan a kilang jet lingkaran–sistem pemprosesan serbuk logam ultrafine berasaskan.

1. Deaglomerasi Awal & Pra-pengkelasan — Kilang Jet Lingkaran

- Fungsi:

Kilang jet lingkaran menjana aliran udara berkelajuan tinggi untuk membentuk pusaran supersonik di dalam ruang pengisaran. Dalam pusaran ini, zarah berlanggar dan bergesel antara satu sama lain, menghasilkan deaglomerasi yang cekap dan mikronisasi awal. - Kelebihan:

Zon klasifikasi dinamik terbina dalamnya secara berkesan mengeluarkan kebanyakan zarah kasar, mengurangkan beban pada pengelasan hiliran dan menghapuskan pencemaran daripada sentuhan mekanikal.

2. Pengelasan Ultrafine Tepat

Selepas pra-rawatan oleh kilang jet lingkaran, pengelasan halus dicapai dengan melaraskan tekanan udara dan kelajuan roda pengelas.

Sistem ini memecahkan aglomerat secara menyeluruh dan mengeluarkan zarah bersaiz besar, memastikan pengedaran saiz zarah yang sangat sempit yang memenuhi keperluan D99 yang ketat.

Keputusan Pelaksanaan

Selepas pentauliahan dan beberapa pusingan pengoptimuman, sistem berjaya memenuhi spesifikasi saiz zarah serbuk logam yang ketat pelanggan:

| Indeks Prestasi Utama | Sasaran | sebenarnya | Penilaian |

|---|---|---|---|

| D99 | ≤ 8 μm | 7.58 μm | Melebihi sasaran |

| Taburan Saiz Zarah | Sangat sempit | Mencapai standard bertaraf dunia | Peningkatan yang ketara |

| Hasil Produk | Kekalkan tahap tinggi | >95% | Kecekapan ekonomi yang tinggi |