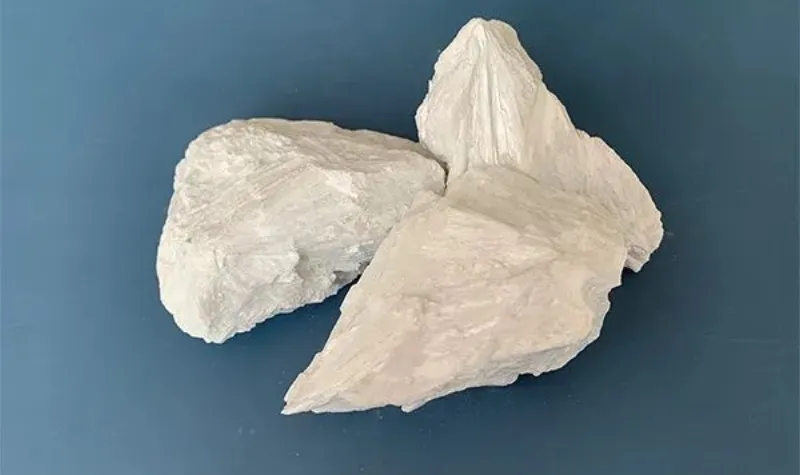

วอลลาสโตน (CaSiO₃) เป็นแร่แคลเซียมซิลิเกตที่มักพบในรูปร่างคล้ายเส้นใยหรือรูปเข็ม โครงสร้างคล้ายเข็มอันเป็นเอกลักษณ์ ผสมผสานกับคุณสมบัติที่เสถียร เคมี มอบคุณสมบัติที่โดดเด่น ได้แก่ ความทนทานต่ออุณหภูมิสูง ความทนทานต่อการสึกหรอ ความทนทานต่อการกัดกร่อน และความสามารถในการเสริมแรง นอกจากนี้ ยังไม่เป็นพิษ ไม่มีกลิ่น และไม่มีกัมมันตภาพรังสี ทำให้เป็นวัสดุที่มีคุณค่าสูง ด้วยความต้องการวัสดุอุตสาหกรรมขั้นสูงที่เพิ่มขึ้น วูลลาสโทไนต์จึงกลายเป็นวัสดุสำคัญ แร่ธาตุที่ไม่ใช่โลหะ, มีศักยภาพอย่างมากสำหรับ การประมวลผลแบบลึกของวอลลาสโทไนต์การประมวลผลเชิงลึกนี้เปิดโอกาสใหม่ๆ สำหรับการใช้งานในอุตสาหกรรมต่างๆ ซึ่งเป็นสัญญาว่าวัสดุอเนกประสงค์ชนิดนี้จะมีอนาคตที่สดใส

การจำแนกประเภทผลิตภัณฑ์วอลลาสโทไนต์

ผลิตภัณฑ์วอลลาสโทไนต์แบ่งออกเป็น 5 ประเภทตาม ขนาดอนุภาค และอัตราส่วนความยาวต่อเส้นผ่านศูนย์กลาง ซึ่งรวมถึงปกติ ผงวอลลาสโทไนต์, ผงละเอียดมากผงโวลลาสโทไนต์ชนิดเข็ม ผงโวลลาสโทไนต์ชนิดละเอียดพิเศษ และผงแปรรูป ผงโวลลาสโทไนต์ชนิดธรรมดาส่วนใหญ่ใช้ในวัสดุเซรามิก เคลือบ ลวดเชื่อม ตะกรันโลหะ และสารตัวเติมสี ผงโวลลาสโทไนต์ชนิดละเอียดพิเศษ (หรือผงละเอียดบริสุทธิ์พิเศษ) ส่วนใหญ่ใช้ในสี พลาสติก และยาง ผงโวลลาสโทไนต์ชนิดเข็มแบ่งออกเป็นผงโวลลาสโทไนต์ชนิดเข็มและผงโวลลาสโทไนต์ชนิดละเอียดพิเศษ โดยมีอัตราส่วนความยาวต่อเส้นผ่านศูนย์กลางมากกว่า 10:1 ใช้เป็นสารเสริมแรงในยางและพลาสติก และเป็นสารตัวเติมเส้นใยสำหรับเบรกคลัตช์รถยนต์และวัสดุเสียดทาน ผลิตภัณฑ์โวลลาสโทไนต์ที่ผ่านการปรับปรุงพื้นผิว ซึ่งผ่านกระบวนการด้วยสารจับคู่ เช่น ไซเลนและบีเทน สารเพิ่มความเข้ากันได้ เช่น มาลิอิกแอนไฮไดรด์ และสารปรับแต่ง เช่น กรดสเตียริก จะถูกนำไปใช้ในยาง พลาสติก สารเคลือบผิว และบรรจุภัณฑ์อิเล็กทรอนิกส์

วอลลาสโทไนต์สามารถเปลี่ยนแปลงและเพิ่มมูลค่าได้อย่างไร?

การคัดเลือกและการทำให้บริสุทธิ์แร่

เป้าหมายของการทำบริสุทธิ์ด้วยแร่วูลลาสโทไนต์คือการกำจัดแร่ธาตุเหล็กที่เป็นอันตรายและลดปริมาณแคลไซต์ เทรโมไลต์ การ์เนต และควอตซ์ วิธีการทั่วไปประกอบด้วยการคัดเลือกด้วยมือ การคัดกรอง การคัดเลือกด้วยไฟฟ้าแม่เหล็ก การลอยตัว และการคัดเลือกแบบผสมผสาน วิธีการที่เหมาะสมขึ้นอยู่กับคุณสมบัติของแร่ธาตุ

การเตรียมวูลลาสโทไนต์ละเอียดพิเศษที่มีอัตราส่วนความยาวต่อเส้นผ่านศูนย์กลางสูง

วูลลาสโทไนต์ชนิดหัวเข็มละเอียดพิเศษสามารถทดแทนแร่ใยหินและใยแก้ว รวมถึงผลึกสังเคราะห์ เพื่อใช้เป็นวัสดุเสริมแรงที่ใช้งานได้จริง เนื่องจากมีต้นทุนต่ำ จึงมีมูลค่าการนำไปใช้ในอุตสาหกรรมอย่างมากและมีศักยภาพทางการตลาดมหาศาล อุปกรณ์หลักที่ใช้ในการบดผงวูลลาสโทไนต์ชนิดหัวเข็มละเอียดพิเศษ ได้แก่ เครื่องบดแบบกระแทกเชิงกล เครื่องบดแบบเจ็ทลม เครื่องบดแบบกวน เครื่องบดแบบเรย์มอนด์ และเครื่องบดแบบสั่นสะเทือน แรงเฉือนและแรงเสียดทานมีแนวโน้มที่จะลอกอนุภาคออกตามระนาบการแยกผลึกในแนวขนานกับทิศทางของแรง แรงเฉือนและแรงเสียดทานที่เหมาะสมจะช่วยแยกกลุ่มผลึกออกเป็นเส้นใยเดี่ยวๆ ซึ่งช่วยในการเตรียมวูลลาสโทไนต์ชนิดหัวเข็มละเอียดพิเศษที่มีอัตราส่วนความยาวต่อเส้นผ่านศูนย์กลางสูง

วอลลาสโทไนต์ที่ดัดแปลง

วอลลาสโทไนต์มีคุณสมบัติชอบน้ำ จึงมีความเข้ากันได้ไม่ดีกับพอลิเมอร์อินทรีย์ เทคนิคการปรับพื้นผิวโดยใช้สารจับคู่ (Coupling Agent) สามารถปรับปรุงคุณสมบัติของมันได้ สารเหล่านี้จะจับกับหมู่ไฮดรอกซิลบนพื้นผิวของวอลลาสโทไนต์ ช่วยเพิ่มความสัมพันธ์และความเข้ากันได้ระหว่างวอลลาสโทไนต์และพอลิเมอร์ วอลลาสโทไนต์ที่ผ่านการดัดแปลงมีการกระจายตัวและการไหลที่ดีเยี่ยม ช่วยเพิ่มความแข็งแรงในการยึดเกาะบริเวณรอยต่อกับพอลิเมอร์ ช่วยเพิ่มคุณสมบัติเชิงกลและคุณสมบัติต้านการเสื่อมสภาพของวัสดุคอมโพสิต วิธีการดัดแปลงทั่วไป ได้แก่ การดัดแปลงเชิงกลและเคมี การเคลือบ, สารจับคู่ และสารเคลือบนาโนอนินทรีย์

ผงมหากาพย์

เทคโนโลยีการบดและการจำแนกประเภทที่ล้ำสมัยของ Epic Powder ช่วยเพิ่มประสิทธิภาพการประมวลผลแบบลึกของวัสดุวูลลาสโทไนต์ ซึ่งช่วยให้สามารถผลิตผงละเอียดพิเศษคุณภาพสูงและผลิตภัณฑ์ที่ผ่านการปรับแต่งพื้นผิวได้อย่างมีประสิทธิภาพ Epic Powder นำเสนออุปกรณ์ที่ทันสมัย เช่น เครื่องบดเจ็ท เครื่องบดกวน และเครื่องจำแนกประเภทอากาศ ซึ่งเป็นสิ่งจำเป็นสำหรับการแปรรูปวูลลาสโทไนต์ เพื่อตอบสนองความต้องการที่หลากหลายของอุตสาหกรรมต่างๆ เช่น สารเคลือบผิว ยาง พลาสติก และอิเล็กทรอนิกส์ การใช้ประโยชน์จากเทคโนโลยีเหล่านี้จะช่วยขยายขอบเขตการใช้งานในอุตสาหกรรมของวูลลาสโทไนต์ ปลดล็อกศักยภาพที่สำคัญสำหรับนวัตกรรมและการเติบโตของตลาด