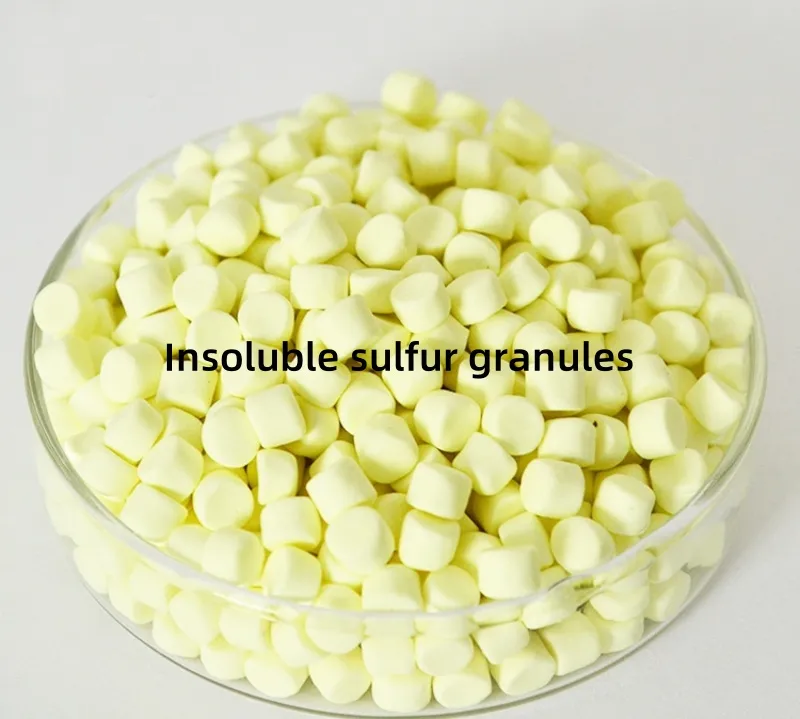

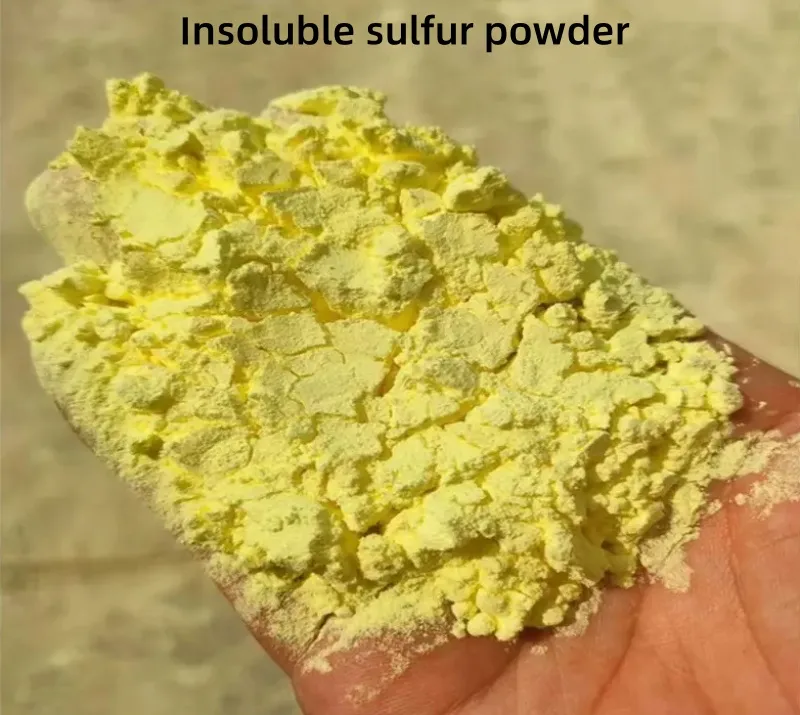

Нерастворимая сера (IS) является основной добавкой в резиновой промышленности, и ее размер частицы Распределение напрямую влияет на его дисперсность и эксплуатационные характеристики продукта. Традиционное механическое измельчение сталкивается со следующими проблемами:

- Термочувствительность: IS деполимеризуется в обычную серу при температуре выше 105°C, теряя свои функциональные свойства.

- Риск взрыва: Серная пыль с размером частиц <75 мкм имеет минимальную энергию воспламенения всего 1–3 мДж (стандарт ASTM E1226).

- Статическое накопление: Трение серы генерирует статическое электричество с потенциалом >5 кВ (оценка EN 1127-1).

Мельницы воздушные классификаторыБлагодаря своей низкотемпературной, инертной среде и возможности точной классификации они стали идеальным выбором для измельчения IS.

Принцип работы Воздушный классификатор Мельница

Ан мельница воздушного классификатора Эффективное измельчающее устройство, сочетающее в себе воздействие воздушного потока и механических сил. Высокоскоростной воздушный поток используется для измельчения и классификации материала. Основной принцип работы заключается в следующем:

Процесс шлифования: После попадания материала в мельницу поток воздуха разгоняет его до высокой скорости. Столкновения и трение между материалом и измельчающими пластинами создают сдвигающие силы, которые измельчают материал до мелких частиц.

Процесс классификации: Материал классифицируется по размеру частиц с помощью вращающегося воздушного потока и классификационного устройства. Крупные частицы возвращаются на дальнейшее измельчение, а мелкие выводятся через классификационное устройство.

Уникальность воздуха-классификационная мельница Благодаря способности точно контролировать распределение размера частиц, повышая однородность и чистоту продукта, использование воздушной классификации позволяет избежать проблем, связанных с переизмельчением и потерями материала, характерных для традиционных методов измельчения.

Параметры процесса:

| Параметр | Значение параметра |

| Размер корма | ≤3 мм (после предварительного дробления) |

| Скорость вращения колеса классификатора | 1150–8500 об/мин |

| Объем воздуха в системе | 800–1200 м³/ч |

| Инертный газ | Чистота азота ≥99,99% |

Уникальность воздушной классификаторной мельницы заключается в её способности точно контролировать распределение размера частиц, повышая однородность и чистоту продукта. Использование воздушной классификации позволяет избежать проблем переизмельчения и потерь материала, характерных для традиционных методов измельчения.

Процесс измельчения нерастворимой серы

Нерастворимая сера – это химический Вещество с низкой растворимостью и высокой температурой плавления, контроль размера его частиц имеет решающее значение для его конечного применения. Процесс измельчения нерастворимой серы в воздушно-сепараторной мельнице обычно включает следующие этапы:

Предварительная обработка материала: Нерастворимое серное сырье предварительно просеивают, чтобы убедиться, что размер его частиц подходит для мельницы.

Переработка и классификацияВ воздушной классификаторной мельнице высокоскоростной поток воздуха разгоняет серу до высокой скорости. Благодаря многократным ударам и трению материал постепенно измельчается до требуемого размера частиц.

Классификация и восстановление: В процессе измельчения классификационное устройство автоматически сортирует частицы по размеру. Крупные частицы возвращаются на повторное измельчение, а мелкие частицы, прошедшие отбор, выбрасываются потоком воздуха, завершая процесс измельчения.

В этом процессе необходимо контролировать такие факторы, как скорость воздушного потока, скорость измельчающего диска и скорость подачи, чтобы обеспечить эффективность измельчения и равномерное распределение размера частиц.

Технология предотвращения взрывов в процессе измельчения

При измельчении нерастворимой серы существует высокий риск взрыва пыли из-за её горючести. Для предотвращения этой угрозы безопасности в конструкции и эксплуатации воздушно-сепарирующего агрегата необходимо реализовать ряд мер взрывобезопасности:

Контроль атмосферы:

Инертные газы (например, азот) заменяют воздух в качестве среды воздушного потока, снижая концентрацию кислорода и риск возгорания и взрыва. Азот эффективно снижает вероятность возгорания и взрыва.

Система пылеподавления:

Эффективная система пылеудаления обеспечивает удаление пыли из воздуха через коллекторы и системы рекуперации воздуха, что снижает накопление пыли. Вокруг зоны шлифования поддерживается отрицательное давление, предотвращающее утечку пыли во внешнюю среду.

Взрывозащищенные устройства:

Воздушный сепаратор должен быть оснащён взрывозащищёнными устройствами, соответствующими международным стандартам. К числу стандартных взрывозащищённых устройств относятся взрыворазрядные клапаны, изолирующие устройства и системы сброса давления. При превышении внутреннего давления определённого порога или возникновении нештатной ситуации эти устройства срабатывают, сбрасывая взрывное давление наружу, защищая оборудование и операторов.

Мониторинг температуры:

В процессе шлифования трение и скорость воздушного потока могут привести к повышению температуры оборудования. Превышение температуры может привести к возгоранию, поэтому используются датчики температуры для мониторинга температуры в зоне шлифования в режиме реального времени. Если температура превышает заданное значение, система автоматически подаёт сигнал тревоги и инициирует меры по охлаждению.

Электрическая взрывозащищенная конструкция:

Электрическая система воздушно-сепарирующего завода должна быть взрывобезопасной, чтобы предотвратить взрыв пыли из-за электрических искр. Это включает в себя использование взрывозащищенных двигателей, выключателей, кабелей и обеспечение надлежащего заземления оборудования.

Эксплуатационные процедуры и обучение:

Операторы должны пройти тщательное обучение по взрывобезопасности, чтобы ознакомиться с использованием и обслуживанием взрывозащищённого оборудования. Также должны быть разработаны подробные процедуры безопасной эксплуатации, такие как регулярные проверки систем вентиляции, пылеудаления и взрывозащищённых устройств для обеспечения безопасной работы оборудования.

Эпический порошок

Воздушная классификаторная мельница Epic Powder не только повышает эффективность измельчения и качество продукта из нерастворимой серы, но и обеспечивает важнейшие функции безопасности, эффективно предотвращая риск взрыва пыли. Используя передовую технологию воздушной классификации, Epic Powder обеспечивает контролируемый процесс измельчения с точным распределением размеров частиц, минимизируя риски, связанные с традиционными методами измельчения. По мере развития технологий измельчения воздушная классификаторная мельница Epic Powder будет оставаться лидером в области эффективного и безопасного измельчения нерастворимой серы и широкого спектра других химических материалов.