লিথিয়াম কার্বনেট (Li₂CO₃) লিথিয়াম ব্যাটারি শিল্প শৃঙ্খলের অন্যতম প্রধান কাঁচামাল। এটি পাওয়ার ব্যাটারি, শক্তি সঞ্চয় ব্যাটারি এবং ভোক্তা ইলেকট্রনিক্সের জন্য ক্যাথোড উপকরণ সংশ্লেষণে ব্যাপকভাবে ব্যবহৃত হয়। নতুন শক্তি যানবাহন এবং শক্তি সঞ্চয়ের দ্রুত বৃদ্ধির সাথে সাথে, প্রয়োজনীয়তাগুলি লি₂কো₃ বিশুদ্ধতা, কণা আকার বিতরণ এবং বিচ্ছুরণ বৃদ্ধি পাচ্ছে। উন্নত লিথিয়াম ব্যাটারি উপকরণের চাহিদা মেটাতে, জেট মিল অতি সূক্ষ্ম গুঁড়োকরণের জন্য একটি অপরিহার্য প্রযুক্তি হয়ে উঠেছে এবং শ্রেণীবিভাগ এর লিথিয়াম কার্বনেট.

লিথিয়াম কার্বনেটের বৈশিষ্ট্য এবং প্রয়োগ

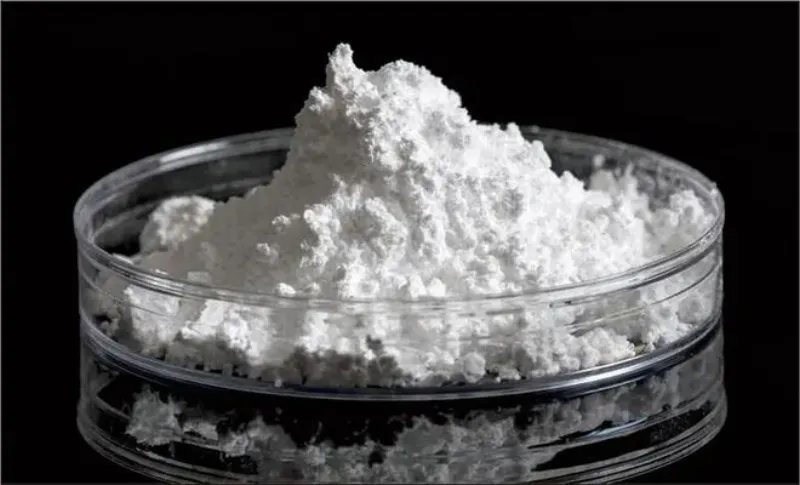

লিথিয়াম কার্বনেট হল একটি সাদা স্ফটিক পাউডার যার উচ্চ রাসায়নিক বিশুদ্ধতা, ভালো তাপীয় স্থিতিশীলতা এবং প্রতিক্রিয়াশীলতা। লিথিয়াম ব্যাটারি প্রয়োগে, এটি প্রধানত নিম্নলিখিত ক্ষেত্রে ব্যবহৃত হয়:

- ক্যাথোড উপাদান সংশ্লেষণ: যেমন LiFePO₄ (LFP) এবং ত্রিমাত্রিক উপকরণ (NCM/NCA)।

- ইলেক্ট্রোলাইট এবং সিরামিক: নির্দিষ্ট লিথিয়াম লবণের পূর্বসূরী হিসেবে অথবা সিরামিক সংযোজন হিসেবে।

- অপটিক্যাল এবং ফার্মাসিউটিক্যাল অ্যাপ্লিকেশন: বিশেষ কাচ, সিরামিক এবং ফার্মাসিউটিক্যাল ইন্টারমিডিয়েটের জন্য।

এই অ্যাপ্লিকেশনগুলি কঠোর প্রয়োজনীয়তা আরোপ করে কণা আকার: ধারাবাহিক বিক্রিয়া এবং কর্মক্ষমতা নিশ্চিত করার জন্য কণাগুলিকে অতি সূক্ষ্ম, সমানভাবে বিতরণ করা এবং বৃহৎ সমষ্টি থেকে মুক্ত থাকতে হবে। পাওয়ার ব্যাটারি-গ্রেড লিথিয়াম কার্বনেটের জন্য, সংকীর্ণ বিতরণ (PDI < 0.3) সহ D50 ≤ 5 μm সাধারণত প্রয়োজন হয়।

এর সুবিধা জেট মিলিং লিথিয়াম কার্বনেট প্রক্রিয়াকরণে

জেট মিলিং অতি সূক্ষ্ম গুঁড়োকরণ অর্জনের জন্য উচ্চ-বেগের গ্যাস প্রবাহ ব্যবহার করে। ভেনচুরি ত্বরণ (0.8–1.2 MPa) সহ, কণাগুলি একে অপরের সাথে সংঘর্ষে লিপ্ত হয় এবং চূর্ণবিচূর্ণ হয়। সমন্বিত শ্রেণিবদ্ধকারী (3,000–5,000 rpm) সুনির্দিষ্ট কাট আকার নিয়ন্ত্রণ (±0.5 μm) অর্জন করে। স্ফটিককরণের জলের ক্ষতি রোধ করতে তাপমাত্রা 80°C এর নিচে রাখা হয়।

লিথিয়াম কার্বনেট প্রক্রিয়াকরণের সুবিধার মধ্যে রয়েছে:

- উচ্চ বিশুদ্ধতা

- ধাতব পরিধান থেকে গৌণ দূষণ এড়াতে, কোনও গ্রাইন্ডিং মিডিয়া নেই।

- সঠিক কণা আকার নিয়ন্ত্রণ

- ক্লাসিফায়ার ইন্টিগ্রেশনের মাধ্যমে সংকীর্ণ বন্টন সহ 1-25 μm এর মধ্যে সামঞ্জস্যযোগ্য।

- নিম্ন-তাপমাত্রা প্রক্রিয়াকরণ

- সম্প্রসারণ শীতলকরণ মিলিংয়ের সময় পচন বা জমাট বাঁধা রোধ করে।

- চমৎকার বিচ্ছুরণ

- উচ্চ-গতির বায়ুপ্রবাহ কণাগুলিকে ডিগ্লোমেরেট করে, নিম্ন প্রবাহের সংশ্লেষণে একজাতীয়তা উন্নত করে।

- অটোমেশন সামঞ্জস্য

- বৃহৎ আকারের উৎপাদনের জন্য ক্লোজড-লুপ সিস্টেম, ধুলো সংগ্রহ এবং স্বয়ংক্রিয় প্যাকেজিংয়ের সাথে একীভূত করা যেতে পারে।

সাধারণ প্রয়োগের ক্ষেত্রে

- LiFePO₄ পূর্বসূরী সংশ্লেষণ: জেট-মিলড লিথিয়াম কার্বনেট অভিন্ন কণার আকার নিশ্চিত করে, লোহা এবং ফসফেট লবণের সাথে আরও সম্পূর্ণ বিক্রিয়া সক্ষম করে, বৈদ্যুতিক রাসায়নিক কর্মক্ষমতা উন্নত করে।

- টার্নারি প্রিকার্সার সংশ্লেষণ (NCM/NCA): সুন্দর এবং অভিন্ন লি₂কো₃ Ni-Co-Mn ম্যাট্রিক্সে অনুপ্রবেশ বৃদ্ধি করে, প্রতিক্রিয়া দক্ষতা উন্নত করে এবং একজাতীয়তা সিন্টার করে।

- সিরামিক এবং অপটিক্যাল গ্লাস: অতি সূক্ষ্ম লিথিয়াম কার্বনেট কাচের স্বচ্ছতা এবং সিরামিক ঘনত্ব উন্নত করে।

এপিক পাউডার

লিথিয়াম ব্যাটারি শিল্পের ক্রমবর্ধমান বিকাশের সাথে সাথে, নির্ভুল লিথিয়াম কার্বনেট প্রক্রিয়াকরণের চাহিদা ক্রমশ বৃদ্ধি পাচ্ছে। শূন্য দূষণ, নিয়ন্ত্রিত কণার আকার, নিম্ন-তাপমাত্রার অপারেশন এবং চমৎকার বিচ্ছুরণের সুবিধা সহ, জেট মিলগুলি অতি সূক্ষ্ম লিথিয়াম কার্বনেট পাল্পারাইজেশনের মূল সরঞ্জাম হয়ে উঠেছে।

অতি সূক্ষ্ম পাউডার প্রক্রিয়াকরণে ২০ বছরেরও বেশি দক্ষতা সম্পন্ন এপিক পাউডার, কাস্টমাইজড জেট মিলিং সিস্টেম সমাধান প্রদান করে, যা গুঁড়োকরণ, শ্রেণীবিভাগ, ধুলো সংগ্রহ এবং অটোমেশন নিয়ন্ত্রণকে অন্তর্ভুক্ত করে। আমাদের সরঞ্জামগুলি ১-২৫ μm কণা আকারের প্রয়োজনীয়তা পূরণ করে, উচ্চ বিশুদ্ধতা, কম শক্তি খরচ এবং স্থিতিশীল বৃহৎ আকারের উৎপাদন নিশ্চিত করে।

LiFePO₄ থেকে শুরু করে টারনারি ক্যাথোড উপকরণ, সিরামিক এবং অপটিক্যাল গ্লাস পর্যন্ত, এপিক পাউডার সমাধানগুলি ক্লায়েন্টদের পণ্যের কর্মক্ষমতা এবং উৎপাদন দক্ষতা সর্বাধিক করতে সহায়তা করে।

এপিক পাউডার নির্বাচন করা মানে উচ্চমানের Li₂CO₃ প্রক্রিয়াকরণে একজন বিশ্বস্ত অংশীদার নির্বাচন করা। উন্নত সরঞ্জাম এবং পেশাদার প্রযুক্তিগত সহায়তার মাধ্যমে, আমরা নতুন শক্তি এবং উন্নত উপকরণ শিল্পে সাফল্য অর্জনের জন্য প্রতিশ্রুতিবদ্ধ।