With the continuous development of advanced technology, advanced ceramic powders and products have become key and bottleneck materials in certain high-tech fields. In the lithium battery industry, some ceramic materials play crucial roles in its production chain. These materials may directly serve as electrodes or separator materials, be used as packaging materials, or act as auxiliary materials in the production process. This ceramic materials market has been booming due to the demand from the lithium battery sector. Today, let’s take a closer look at which ceramic materials are required to produce a lithium battery.

Lithium-ion batteries are mainly composed of five parts: cathode material, anode material, separator, electrolyte, and packaging material. Among them, the separator is the most technically challenging part of the матэрыял батарэі, with its cost accounting for 10% to 14%, second only to the cathode material. In high-end batteries, the separator cost can even account for as much as 20%.

Traditional Separator Disadvantages

The commercialized lithium-ion battery separators are mainly microporous membranes made of polyethylene (PE) or polypropylene (PP). These polyolefin separators have certain drawbacks. On the one hand, when external temperatures reach or exceed the melting point of the separator, the separator may shrink or melt, leading to internal thermal runaway or short-circuiting in the battery. Therefore, maintaining the separator’s size and shape is crucial for improving battery safety. On the other hand, because the polarity of polyolefin separators does not match that of organic electrolytes, the separator has poor wetting with the electrolyte, which means that during repeated charge-discharge cycles, the separator’s ability to retain the non-aqueous electrolyte is weak, thus affecting the battery’s cycling performance.

Advantages of Ceramic Separators and Representative Materials

Currently, ceramic separators can be divided into two categories based on their preparation methods. One method involves using traditional polyolefin separators or nonwoven fabrics as a base membrane. A layer of ceramic пакрыццё is then applied using methods like bonding, hot pressing, or grafting. The other method involves mixing nano-sized ceramic particles into organic materials to create a slurry. This slurry is then stretched into films or made into nonwoven fabrics.

With the widespread use of tablets and electric vehicles, traditional polyolefin separators can no longer meet high-voltage and high-energy-density requirements. This is due to their poor performance in terms of high-pressure and high-temperature resistance. By using separator coating technologies, ceramic coatings can prevent thermal runaway points in the battery from expanding. This ensures better safety. The unique structure of inorganic materials also improves the separator’s resistance to thermal shrinkage. Additionally, ceramic coatings possess hydrophilic properties. These properties enhance electrolyte absorption, which can improve the uniformity of current distribution within the battery during charge and discharge cycles.

The most widely studied ceramic separator materials are high-purity alumina (Al2O3) and boehmite (AlOOH).

High-Purity Alumina (Al2O3)

Alumina is a high-hardness compound with a melting point of 2054°C and a boiling point of 2980°C. It is an ionically bonded crystal with high thermal stability and хімічны inertness, making it an excellent choice for ceramic coatings on battery separators. The advantages of high-purity alumina include:

- Long Cycle Life: It reduces mechanical micro-short circuits during the cycling process, effectively enhancing the cycle life.

- High Rate Performance: High-purity nano alumina can form solid solutions in lithium batteries, improving the rate performance and cycle stability.

- Excellent Thermal Conductivity: High-purity nano alumina has excellent thermal conductivity, which helps in transferring heat when the battery temperature rises, solving the poor thermal conductivity issue of PP/PE materials.

- Good Wetting Ability: Nano alumina powder has good electrolyte absorption and retention capacity.

- Excellent Flame Retardancy: Alumina is an excellent flame retardant material. Even at high temperatures, its superior flame-retardant properties can prevent widespread combustion or even explosions.

- Current Blocking: In cases of excessive current, high-purity alumina can block the current, preventing short circuits that may result from excessive heat causing the separator to melt.

Boehmite (AlOOH)

Pure boehmite is white, with a monoclinic crystal structure, belonging to the orthorhombic crystal system. It has a Mohs hardness of 3-3.5 and a specific gravity of 3.0-3.07. Boehmite is the precursor of γ-Al2O3 and is used in a wide range of applications, such as ceramic materials, composite materials, surface protection coatings, optical materials, catalysts, and semiconductor materials.

Compared to alumina, boehmite has the following advantages:

- Lower Hardness: Boehmite has lower hardness, which reduces mechanical wear during cutting and coating processes, making it more cost-effective than high-purity alumina.

- High Heat Resistance: Boehmite has excellent thermal stability and good compatibility with organic materials.

- Lower Density: For the same weight, boehmite can cover 25% more area than alumina.

- Better Coating Uniformity: Boehmite coatings are more uniform, resulting in lower internal resistance.

- Lower Energy Consumption: The production process of boehmite is more energy-efficient and environmentally friendly.

- Lower Water Absorption: Boehmite absorbs only half the water that high-purity alumina does.

- Simpler Production: The preparation of boehmite is simpler than that of high-purity alumina, which requires calcination, grinding, and grading.

- Easier to Replace: Switching to boehmite does not require significant changes in the equipment or processes of separator manufacturers, and it causes less damage to equipment.

Cathode Additive – Zirconium Oxide (ZrO2)

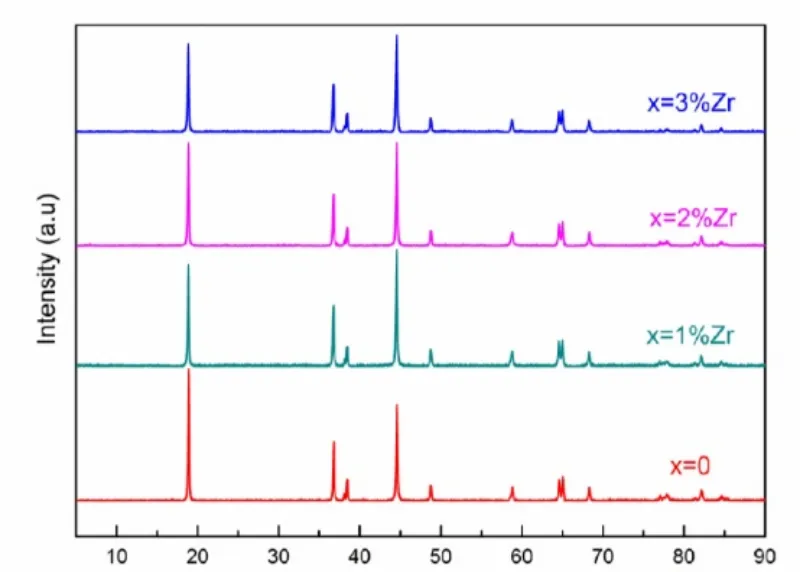

The application of nanoscale zirconium oxide (ZrO2) products in the new energy sector is expanding, with more lithium battery designs incorporating zirconium oxide powder as a cathode additive to stabilize battery performance and increase cycle life. Taking nickel-cobalt-manganese lithium (LiNi0.8Co0.1Mn0.1O2) as an example, let’s examine how nanoscale zirconium oxide influences the performance of cathode materials.

Structural Effects

X-ray diffraction (XRD) analysis of LiNi0.8Co0.1Mn0.1O2 doped with ZrO2 reveals that the addition of ZrO2 does not alter the overall structure of the material, which retains the hexagonal α-NaFeO2-type layered structure typical of the material.

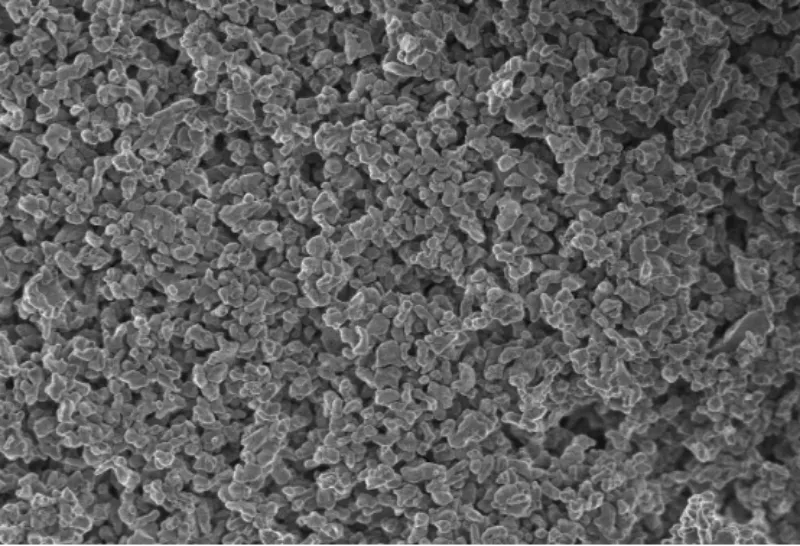

Morphological Effects

As the ZrO2 doping level increases, the size of primary particles decreases from the original 200–400nm-sized regular block particles to 100–200nm-sized dense aggregates. The large particles formed by agglomeration of the primary particles are reduced to 1–2μm. The spherical shape of the particles becomes less pronounced with doping, which facilitates easier lithium-ion diffusion.

Electrochemical Effects

Research indicates that ZrO2-doped materials show higher discharge capacity compared to the original LiNi0.8Co0.1Mn0.1O2. This is likely due to the smaller памер часціц, which reduces the lithium-ion diffusion path and improves electrochemical performance. Moreover, Zr4+ ions may migrate to the surface and form solid solutions, which help prevent structural collapse during charge-discharge cycles and also protect the material from cobalt dissolution, improving cycle stability.

Cathode Materials Sintering – Ceramic Kiln Equipment

With the increasing demand for electric vehicle batteries, the demand for cathode materials has surged, driving domestic kiln manufacturers to upgrade their production equipment. Materials such as silicon carbide ceramics and cordierite-mullite ceramics have seen a significant rise in demand.

Pusher Plates

The commonly used pusher plates are made from silicon carbide and corundum-mullite, with silicon carbide plates primarily used for low-temperature kilns. However, their oxidation at temperatures above 1300°C limits their application.

Crucibles

In terms of crucibles, different materials are used for the sintering of cathode materials. Cordierite-mullite crucibles are widely used in the lithium battery cathode material sector due to their excellent thermal shock resistance and cost-effectiveness.

Rollers

Rollers used in roller kilns, which are commonly used in the sintering of lithium-ion battery cathode materials, must withstand high temperatures and be resistant to creep deformation. The materials commonly used for ceramic rollers include corundum, aluminosilicate, fused silica, and silicon carbide.

Other Lithium Battery Ceramic Materials

In addition, other ceramic powders or products are also used in the preparation or assembly of lithium batteries. For example, high-purity ultrafine alumina is used as a cathode additive, playing a role in coating and doping. Silicon carbide micropowder can be combined with graphite, carbon nanotubes, or nano-titanium nitride to form anode materials. This combination improves battery capacity and lifespan. In the sealing process of lithium batteries, electronic ceramic rings are essential components. These rings are also known as “new-type power battery ceramic sealing connectors.” They form a sealed conductive connection between the battery cover and poles in electric vehicles.

Заключэнне

With the continuous development of advanced technologies and materials, it is likely that more lithium battery ceramic materials will be applied in lithium batteries and the entire new energy sector in the future.

«Дзякуй за чытанне. Спадзяюся, мой артыкул будзе карысным. Калі ласка, пакіньце каментар ніжэй. Вы таксама можаце звязацца з прадстаўніком службы падтрымкі кліентаў Zelda онлайн, калі ў вас ёсць дадатковыя пытанні».

— Апублікавана Эмілі Чэн