Гідраксід натрыю (NaOH), шырока вядомы як каўстычная сода, з'яўляецца шырока выкарыстоўваным і неабходным прамысловым рэчывам хімічныЁн адыгрывае важную ролю ў хімічнай вытворчасці, ачыстцы вады, а таксама ў вытворчасці мыла і мыйных сродкаў. Нягледзячы на шырокае прымяненне, многія сучасныя галіны прамысловасці патрабуюць больш дробных парашкоў гідраксіду натрыю. Каб задаволіць гэтую патрэбу, класіфікатар паветра млын стала эфектыўным рашэннем для вытворчасці ультратонкага парашка гідраксіду натрыю. У гэтым артыкуле разглядаюцца ўласцівасці і прымяненне гідраксіду натрыю, а таксама перавагі выкарыстання паветраны класіфікатар млын у сваім парашковае памолванне.

Гідраксід натрыю: уласцівасці і прымяненне

Гідраксід натрыю — гэта высокашчолачнае злучэнне, якое звычайна даступна ў цвёрдых формах, такіх як шматкі, гранулы або парашкі, і яно добра раствараецца ў вадзе. Яго асноўныя функцыі ўключаюць:

- Хімічная вытворчасць: Выкарыстоўваецца для вытворчасці хімічных рэчываў, такіх як хлор, карбанат натрыю, і сінтэтычныя валокны. Гэта найважнейшы рэагент у рэакцыях амылення (мылаварэння) і нейтралізацыі.

- Ачыстка вады: Выкарыстоўваецца для нейтралізацыі кіслот, змякчэння вады і выдалення цяжкіх металаў і іншых прымешак.

- Вытворчасць мыла і мыйных сродкаў: Дзейнічае як асноўны рэагент з тлустымі кіслотамі ў працэсе амылення для атрымання мыла.

- Цэлюлозна-папяровая прамысловасць: Пры хімічнай варцы цэлюлозы гідраксід натрыю растварае лігнін, каб аддзяліць цэлюлозныя валокны.

Хоць гідраксід натрыю звычайна выкарыстоўваецца ў вадкім або грануляваным выглядзе, у некаторых выпадках патрабуецца дробны парашок. Парашкападобная форма павышае рэакцыйную здольнасць і дазваляе больш дакладна кантраляваць хімічныя рэакцыі.

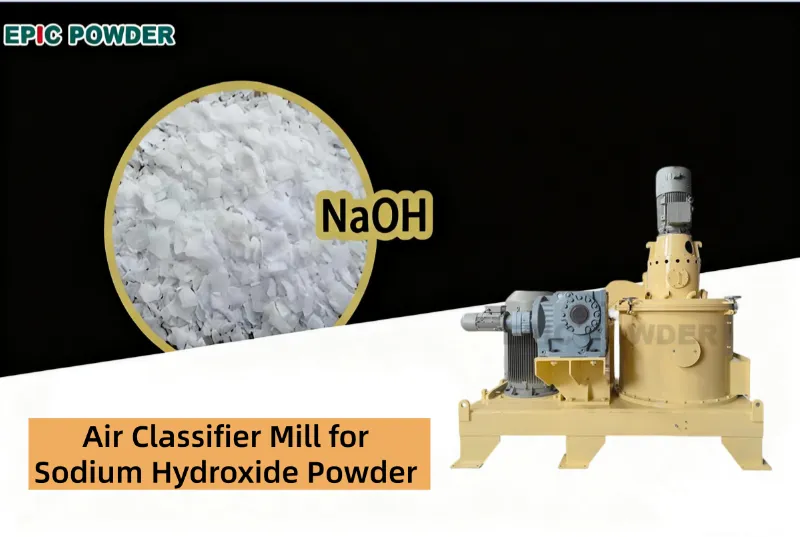

Паветраны класіфікатар млынІдэальны інструмент для драбнення парашка гідраксіду натрыю

Класіфікацыйны млын — гэта перадавое абсталяванне для апрацоўкі парашка, прызначанае для вытворчасці ультратонкіх парашкоў. Ён выкарыстоўвае механічнае ўздзеянне ў спалучэнні з паветранай класіфікацыяй для эфектыўнага здрабнення часціц, а класіфікацыйнае кола забяспечвае дакладнае падзел, у выніку чаго атрымліваюцца прадукты з вузкай... памер часціц размеркаванне.

Для гідраксіду натрыю, памер часціц непасрэдна ўплывае на прадукцыйнасць наступных прыкладанняў. Традыцыйнае механічнае шліфаванне часта прыводзіць да:

- Моцная агламерацыя часціц

- Нераўнамернае размеркаванне памераў часціц (D50 звычайна >100 мкм)

- Паглынанне вільгаці і злежванне падчас апрацоўкі

Тэхналогія класіфікацыйнага млына эфектыўна вырашае гэтыя праблемы, спалучаючы высакахуткасны ўдар з дакладнай класіфікацыяй.

Прынцып працы і аптымізацыя параметраў ACM

Прынцып працы:

Пад дзеяннем хуткаснага ротара матэрыялы падвяргаюцца:

- Ударнае шліфаванне (сутыкненні часціц з высокай хуткасцю)

- Шліфаванне зрухам (трэнне паміж часціцамі і ротарам або ўнутранай сценкай)

Дзякуючы кіраванню ў рэжыме рэальнага часу класіфікацыйным колам, канчатковы памер часціц можна дакладна рэгуляваць у межах 5–45 мкм дыяпазон.

Перавагі Дробленне гідраксіду натрыю Парашок з паветраным класіфікацыйным млыном

- Ультратонкае шліфаванне: Дасягае памераў часціц мікраннага або нават субмікроннага ўзроўню, што павышае рэакцыйную здольнасць гідраксіду натрыю і спрыяе лепшаму кантролю хімічных рэакцый.

- Нізкатэмпературнае шліфаванне: Класіфікацыйны млын выпрацоўвае мінімальную колькасць цяпла падчас драбнення, што дапамагае прадухіліць рэакцыі акіслення або гідратацыі гідраксіду натрыю і падтрымліваць яго хімічную актыўнасць.

- Высокая энергаэфектыўнасць: У параўнанні з традыцыйнымі метадамі, такімі як шаровы млын, класіфікацыйны млын прапануе больш высокую энергаэфектыўнасць, што робіць яго больш прыдатным для буйнамаштабнай бесперапыннай вытворчасці.

- Нізкае забруджванне: Інтэграваныя працэсы драбнення і класіфікацыі мінімізуюць рызыку забруджвання знешнімі мелючымі матэрыяламі.

- Высокая прапускная здольнасць: Абсталяванне можа працаваць бесперапынна, забяспечваючы стабільную якасць прадукцыі і задавальняючы патрэбы прамысловай вытворчасці.

- Моцная адаптыўнасць: Здольны працаваць з матэрыяламі на аснове гідраксіду натрыю розных формаў і ўзроўняў цвёрдасці, што забяспечвае шырокае прымяненне.

Прымяненне ультратонкага парашка гідраксіду натрыю

Ультратонкі парашок NaOH мае значную каштоўнасць у галінах прамысловасці, дзе дакладнасць і высокая чысціня маюць важнае значэнне:

- Хімічныя рэакцыі: Больш дробныя часціцы забяспечваюць большую плошчу паверхні, што дазваляе хутчэй праводзіць рэакцыі з больш высокім выхадам.

- Фармацэўтычная прамысловасць: Выкарыстоўваецца для рэгулявання pH у лекавых прэпаратах. Ультратонкі парашок забяспечвае больш дакладны кантроль pH, паляпшаючы фармацэўтычную стабільнасць і эфектыўнасць.

- Касметыка і сродкі асабістай гігіены: У вытворчасці мыла і касметыкі ультрадысперсны гідраксід натрыю забяспечвае лепшую растваральнасць і размеркаванне, паляпшаючы якасць прадукцыі.

- Харчовая прамысловасць: Ужываецца ў харчовай прамысловасці (напрыклад, у прэтцэлях) для рэгулявання pH, з выкарыстаннем дробных парашкоў, якія забяспечваюць кансістэнцыю і бяспеку.

- Ачыстка вады: Ультратонкі парашок хутка раствараецца, эфектыўна нейтралізуючы кіслоты і паляпшаючы якасць вады.

Заключэнне

Выкарыстанне класіфікацыйнага млына ў вытворчасці ультратонкага парашка гідраксіду натрыю прапануе мноства пераваг, якія цесна адпавядаюць растучым патрабаванням у розных галінах прамысловасці. Дзякуючы сваёй дакладнасці, эфектыўнасці і энергазберагальным характарыстыкам, класіфікацыйны млын забяспечвае больш высокую чысціню і прадукцыйнасць пры драбненні парашка гідраксіду натрыю. Незалежна ад таго, ці гэта хімічная вытворчасць, ачыстка вады ці фармацэўтычныя прэпараты, дакладны кантроль памеру часціц і цэласнасць матэрыялу падкрэсліваюць яго важнасць у прамысловай вытворчасці.

EPIC парашок спецыялізуецца на распрацоўцы перадавых тэхналогій паветранага класіфікатара для высокапрадукцыйнай апрацоўкі парашка. Нашы сістэмы забяспечваюць дакладныя памеры ультрадробных часціц, гарантуючы, што ваш парашок гідраксіду натрыю адпавядае самым высокім галіновым стандартам. Дзякуючы нашаму вопыту ў галіне паветранай класіфікацыі і тэхналогій памолу парашка, EPIC Powder з'яўляецца вашым надзейным партнёрам для дасягнення выключных вынікаў апрацоўкі матэрыялаў.